Home › Forum › Ask A Member › Chrysler 55hp 1967 pumping

- This topic has 11 replies, 3 voices, and was last updated 2 years, 7 months ago by

rapier.

-

AuthorPosts

-

August 1, 2021 at 11:08 am #244055

Just rebuild this motor with new crank, pistons, bearings, seals and some replacement gaskets following a head gasket failure and overheat a few years ago. Put it all together with a new 6 blade impeller, but it failed to pump any water from the exhaust snout and still refuses to. Struggling to understand why, as ordinarily this sprays from the exhaust until the thermostat opens and then gushes…

It’s being run in a drum with water up to the lower mounts at 24:1

The inlet water pipe is properly inserted into the pump grommet and there are no obstructions in the grommet.

Have checked the pump and impeller – the pump has little wear and the wear plate is near new (and the impeller running in the right direction)

Have tested the pump operation using a drill to spin the shaft.

Have removed the (new) thermostat (just for the interim..but it opens at the right temp when heated up in a pot of water).

Connected a snug fitting hose to the inlet water pipe (tap cranked slightly open) – water flows through the powerhead and exits the exhaust snout on the midsection, a smaller amount runs down the inside of the midsection.Am wondering whether the seal and washer on the powerhead side of the inlet pipe is to blame – perhaps a loss of pressure?

-

This topic was modified 2 years, 8 months ago by

Mumbles.

Mumbles.

August 1, 2021 at 2:18 pm #244072Won’t the base gasket seal that area?

August 2, 2021 at 5:47 am #244106Yes, the base gasket seals it there, but underneath the casting is a seal and washer that the long inlet pipe I guess push fits into.

I had an idea in the hour before dawn that the under skeg pickup may have been partially blocked, kinked or damaged somehow. Dropped the gearbox and pulled the pump apart again, removed the screen and pushed a rod up it, no obstruction, but plenty of holes / corrosion once I looked closer. Spoke to an old-school Chrysler guy who said it was a common fault as the thin ali pipes used to corrode and cause pumping issues by drawing in air.

-

This reply was modified 2 years, 8 months ago by

Mumbles.

Mumbles.

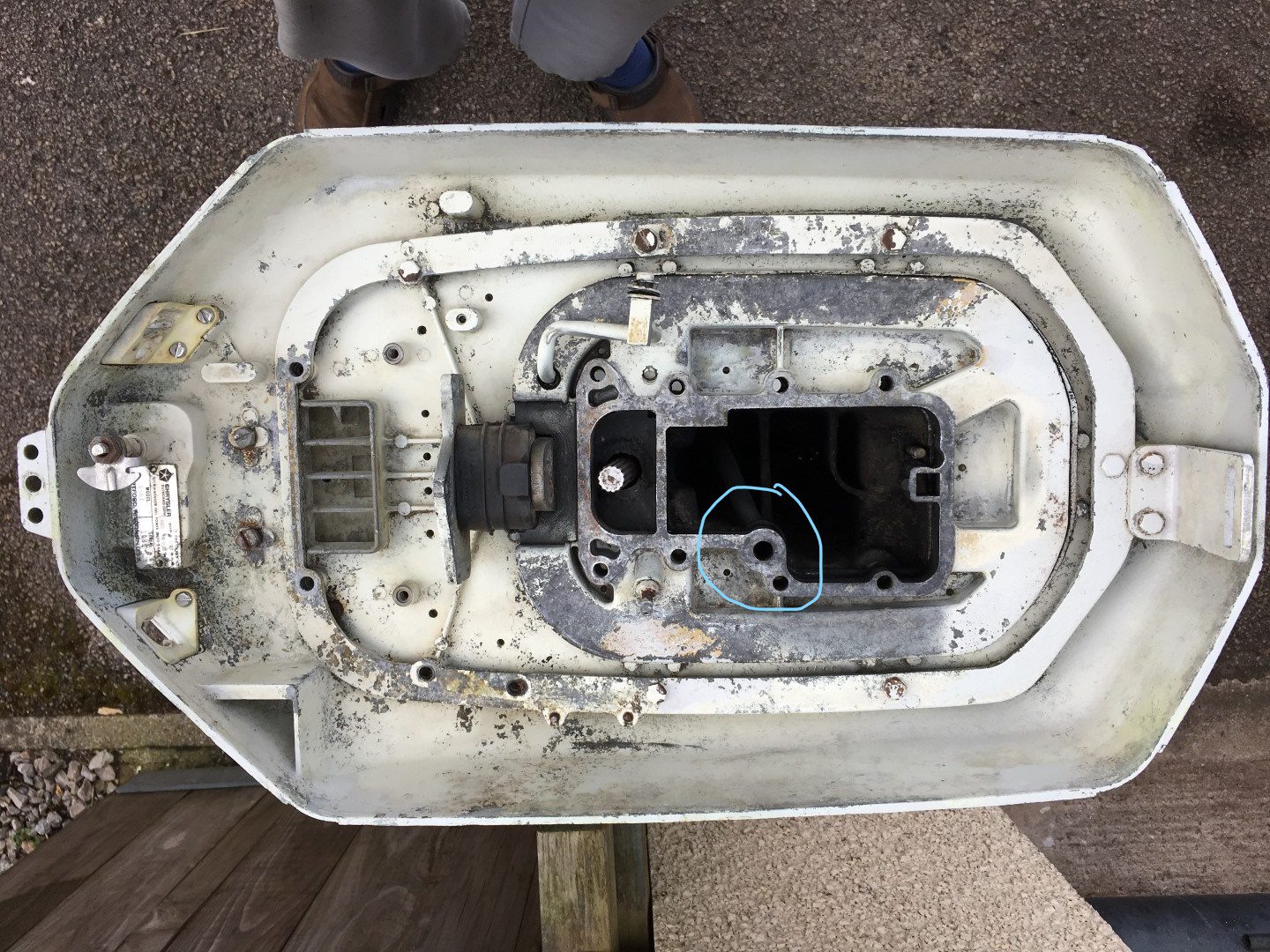

August 21, 2021 at 7:51 am #245249I fixed the pickup tube expecting it to resolve the pumping problem, by priming the pump properly, but still have the same issue. There’s no flow (or spitting) from the exhaust bypass, even when the thermostat is removed. When I looked at the factory parts diagram the ’67 water pump looks like a 3 bolt mount, so I can only assume that the l/u was replaced at some stage and that the parts are interchangeable. My last option is to pull the powerhead – if anyone here has other ideas I’d greatly appreciate them?

-

This reply was modified 2 years, 8 months ago by

Mumbles.

Mumbles.

August 21, 2021 at 9:37 am #245254Is there any smoke coming out of the idle relief port?

September 10, 2021 at 10:08 am #246442A house sale and all that entails stopped work on this. I got grumpy about a lack of progress and pulled the powerhead last weekend and found I’d used the incorrect base gasket in a moment of mental aberration during the rebuild. It wasn’t entirely the cause, but it didn’t help with some of the bypass not exiting the snout, but instead flowing down inside the mid, between the gap in the base plate. Am now in the process of heating and cooling the bolts on the exhaust port cover and plates – a job I hate doing,,but thank Quicksilver for continuing to make 1960s pattern gaskets for the ‘Force’ models. My theory is a long gone owner ‘lost’ a piece of impeller and that’s where it’s lodged, plus collected additional debris over time, so restricting flow.

September 10, 2021 at 11:04 am #246443Don’t be to concerned on mental aberrations … it is no worse then me not lining up a vacum pulse hole on a bypass cover plate with the rear end of a $6.99 fuel pump… with me complaining to the seller and asking for a refund on 6 pumps . 🙁

I am glad the seller refused … I now have 5 good pumps 🙂

Joining AOMCI has priviledges 🙂

September 10, 2021 at 11:05 am #246444I’m glad to see you got this figured out and it was a simple fix. As long as Mercury has parts for Force motors, you should have parts for your Chrysler.

About forty years ago I had a 55 on a 14′ flat bottomed runabout. It was a missile on the water and it took me on many adventures. Through the Gulf Islands one summer, twice across the JDF Straight to Pt Angeles WA and of course countless hours on Cowichan Lake here on the island. I hope your motor gives you as much enjoyment as mine gave to me!

September 15, 2021 at 10:33 am #246706Yes, miles of smiles with it – was an experiment I still don’t regret. Mine is (normally) on my13ft Duratech copy which weighs about 180lb bare.

No progress on this one though. I spent 1 1/2 days with the Map torch, before I broke 8 of 9 – they’re notorious – I should have just taken the heads off and gone from there. At least you can get the 50/50 down the threads. One bolt refuses to give up it’s side hold, so I cannot get the plate off yet.

September 19, 2021 at 8:56 am #246900After breaking the edge of the exhaust cover with the wedges (hopefully my parts supplier can source another for me..), I had to dremel out the exhaust cover to expose the bolt that wouldn’t shift. No sign of a stuck impeller vane, but the lack of water flow / pumping was caused by a build up of salt & grit blocking the (narrow) intake channels in two places – a lack of flushing issue. Will take the powerhead to a machine shop to get the broken studs removed, they’re mild steel and don’t want to shift, despite heating cycles and penetrant.

-

This reply was modified 2 years, 7 months ago by

Mumbles.

Mumbles.

-

This topic was modified 2 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.