Home › Forum › Ask A Member › Restoration of 3hp1964 Johnson JH 19A

- This topic has 2 replies, 2 voices, and was last updated 2 years, 6 months ago by

Monte NZ.

-

AuthorPosts

-

October 16, 2021 at 5:49 am #248145

Hi All

Could someone please let me know the correct high speed fixed jet for the above?The jet in the carburetor when I got the motor, has the number “2” on it, but another carburetor that I have for the same model has “4 A”………may I add, that there is a quite a difference in the size of the hole in the jet.

As the engine has had a hard life and going on things I have had to correct and repair, I thought it might be wise to check.Thanks in advance

Monte NZ

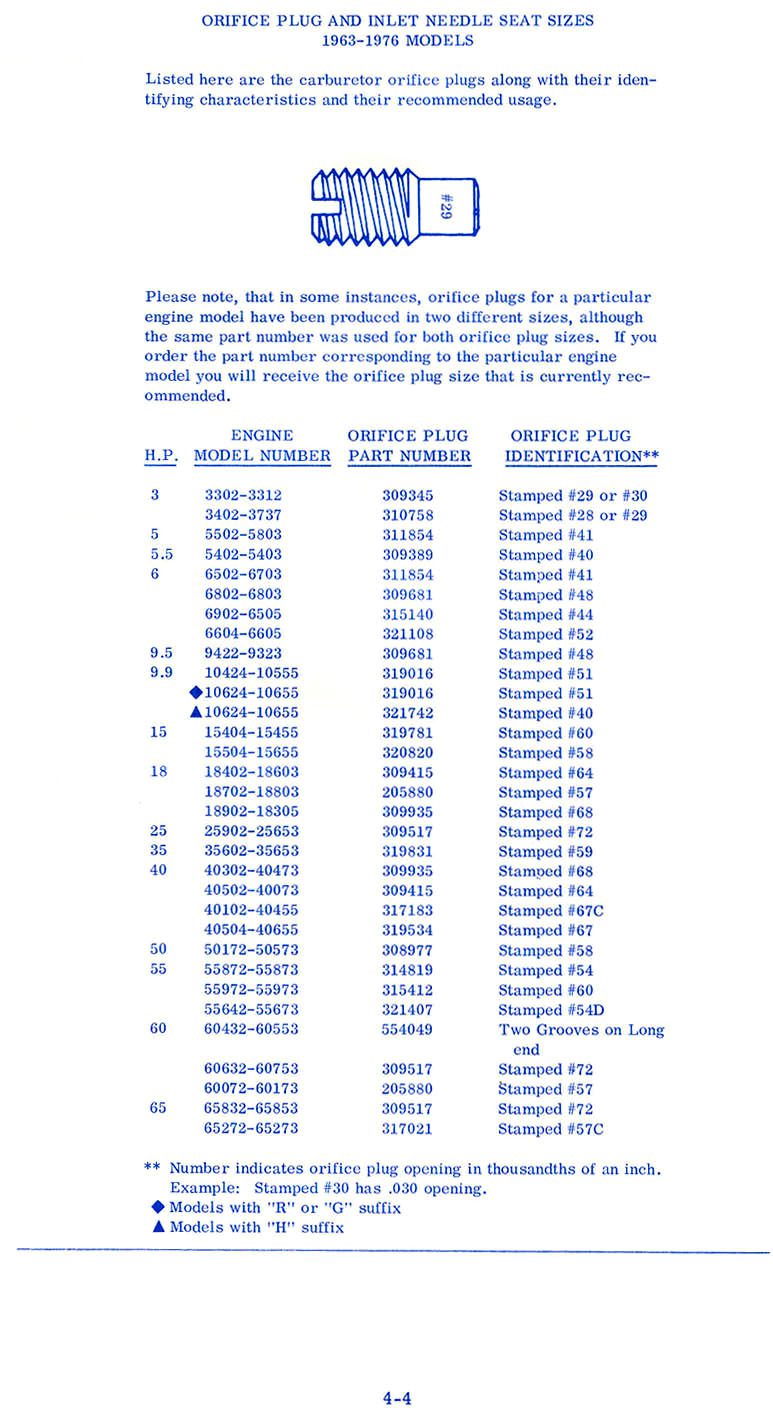

October 16, 2021 at 1:09 pm #248156Marineengine shows the orifice having a passage size of 0.029″. Original P/N 310758 being replaced by 330142.

https://www.marineengine.com/newparts/part_details.php?pnum=OMC0330142

October 18, 2021 at 4:47 am #248251Thanks very much Mumbles………that chart certainly tells it all!

On reading the chart I went and another look at the jet with the #2 on it and discovered on closer inspection, a very faint #8 next to the 2, proving that it was the correct jet and that the hole is 28 thou.

As a further check I tried a 28th thou drill and it fitted perfectly.It’s worth mentioning that it was a hell of a job getting the jet out of the carb bowl as it had been butchered by someone not using the proper screwdriver. Fortunately I had made a proper screwdriver previously, otherwise I would never have got it out!

If it’s any help to others having this problem, I used the following method:-

I cut an inch long piece of 1/8th steel rod and tapered it at one end to fit snuggly into the slotted end of the jet. The idea of the rod was to stop the drill from wandering as I drilled down either side of the steel rod into what was left of the slots on the jet………;.I drilled down about 3/32 either side, then heated the bowl under the jet with my small blowtorch, gently hammered the screwdriver into the extended slots and pressing hard on the screw driver, wound the jet out.Thanks once again.

Monte NZ -

AuthorPosts

- You must be logged in to reply to this topic.