Home › Forum › Ask A Member › 1936 waterwitch

- This topic has 2 replies, 2 voices, and was last updated 7 years, 10 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

September 8, 2017 at 5:39 am #8172

Anonymous

Seeing as there have been some Waterwitch posts lately, thought I’d share some photos of my motor. Since it’s one of several motors that are on my to do list, I haven’t messed with it much. Doesn’t have spark but it "feels" like it has good compression although I haven’t checked it yet. May just have to break down and do that here shortly. When I got the motor, it had a homemade tiller handle and from what I’ve read the original was somewhat fragile so it’s not surprising it must have broke. As can be seen in the photos, the original skeg was trashed and a repair was cobbled together. I got a ’37 gear case and tiller handle off Ebay. The ’37 gear case looks the same dimensionally with the only noticeable difference being some small ports at the top at the top below the cavitation plate. The tiller handle is different but it will serve it’s purpose. The motor obviously has it’s problems but my intent is to see if I can get it running and then decide what to do about the appearance.

Please excuse the rotated pictures which are not that way on my computer. I find them irritating but I can’t figure out how to correct them.

Thanks

KirkSeptember 8, 2017 at 5:42 am #64528September 8, 2017 at 1:27 pm #64534As you have a strong interest in these I’ll

share what I have learned from the ones I’ve

had as well as what others have shared with me.

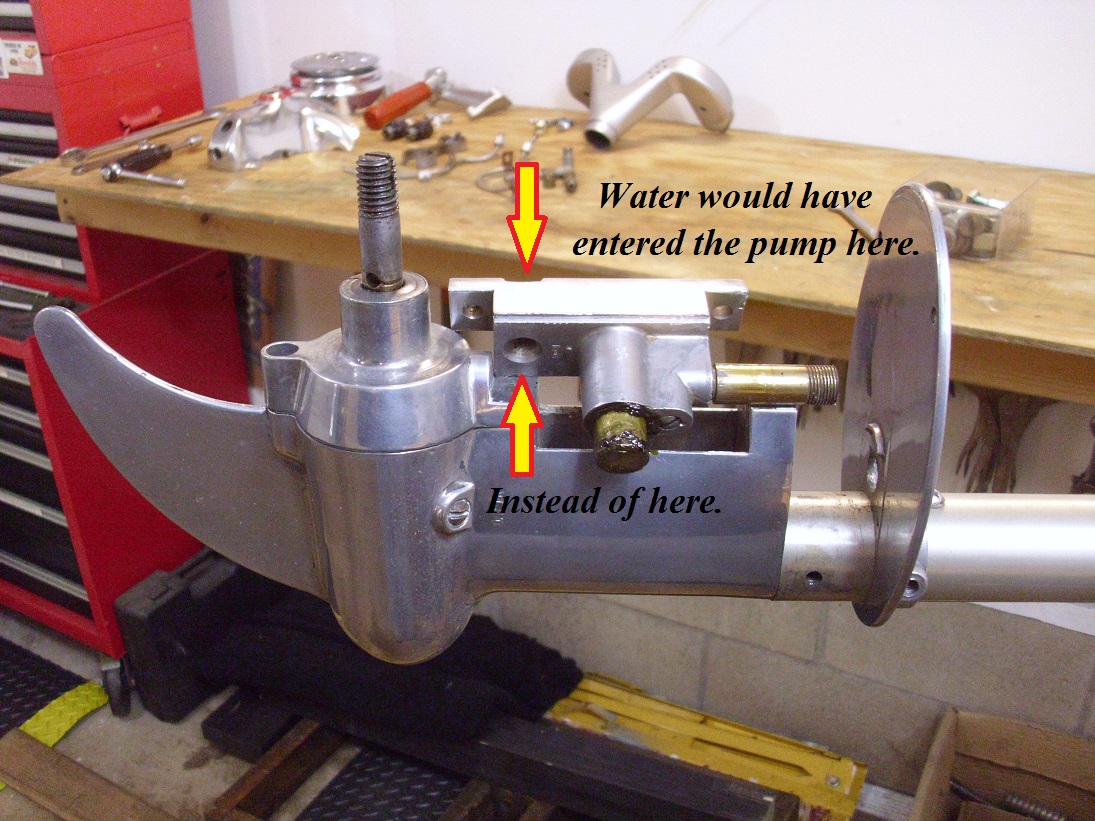

Your motor is a 1936 as the water tube is inside

the exhaust. Only year they did that. We’ve also

discussed the deference in the 36 stands and tiller.

Originally the had intended the have the water

enter the pump through the pump body. This

didn’t provide enough water for cooling so they

put two holes in front of the gear case to increase

the supply of water. I don’t know if any motors

were sold before the change or they discovered

it in testing. The pump castings for the early

design were still used. They just didn’t machine

the hole for the water. The early castings have

this flat spot where the water access hole would

have been.A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.