Home › Forum › Ask A Member › shear pin will not go past thrust washer on prop

- This topic has 8 replies, 6 voices, and was last updated 4 years, 4 months ago by

frankr.

frankr.

-

AuthorPosts

-

December 7, 2019 at 9:39 am #188821

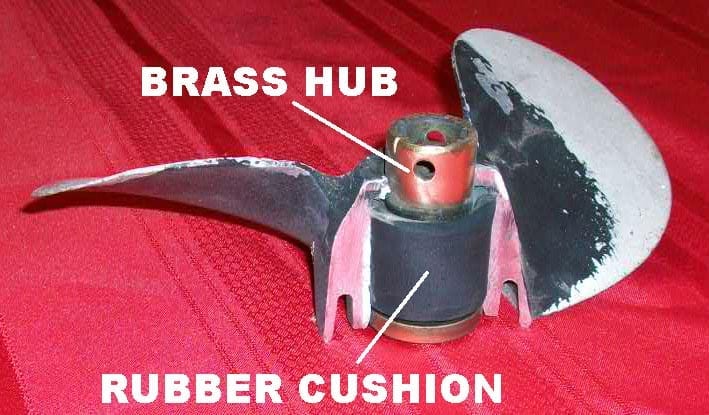

As you can see in the picture the shear pin will go in one side but then hits the edge of the thrust washer on the other side.

The hub is a bit crooked in the prop.

I would like suggestions before I do my idea. Which is use an arbor press

Or

Run the motor without the thrust washer but prop is kind of wobblyDecember 7, 2019 at 10:27 am #188824December 7, 2019 at 11:47 am #188829Another invisible submission

December 7, 2019 at 11:50 am #188830

December 7, 2019 at 11:50 am #188830Garry, no clue as to why it does this, I looked and saw that the post had one hidden post, I clicked that button and viola your post appeared…

I will contact Travis to see if he has any ideas…http://www.richardsoutboardtools.com

classicomctools@gmail.comDecember 7, 2019 at 11:59 am #188831If it were my motor, I would grab the blade closest to the shear pin and push forward hoping to rock the unit a bit so the shear pin will fit. I am sure that the hub is cocked and from the

picture it appears that you will not be able to get the shear pin cover over the end because of the pin sticking out. So you will have to take a hammer and tap the pin so it rides over the brass spacer. Once the pin is in place, the cover fits and the cotter pin is in place, take the motor out for a ride. Hopefully the torque of the motor will correct the hub and make it more centered.December 7, 2019 at 12:24 pm #188832Take a punch or marker and mark the hub and the prop. Go run the motor behind a boat in the water. If the marks have moved the hub is spun. New prop time or hub.

December 7, 2019 at 3:35 pm #188890OK got it

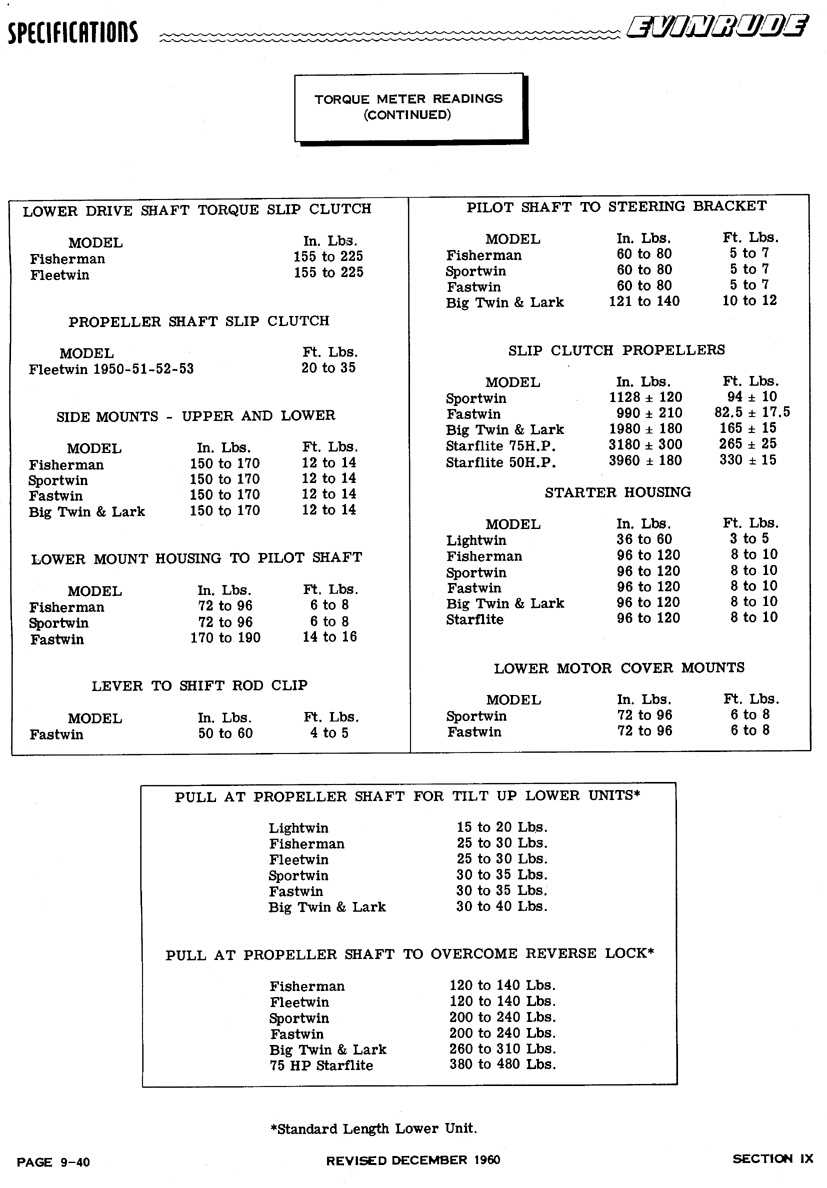

Is there a way to tell if the hub is spun while on dry land?December 7, 2019 at 5:45 pm #188894There is, All you need is the special tool test fixture to hold it and apply the torque. It should hold 150-180 foot pounds of torque. I made myself a test fixture back in “The Day”. It broke a hunk out of a prop blade.

December 7, 2019 at 6:26 pm #188828

-

AuthorPosts

- You must be logged in to reply to this topic.