Home › Forum › Ask A Member › Repairing A Broken Needle Valve

- This topic has 9 replies, 7 voices, and was last updated 2 years, 8 months ago by

need2fish.

-

AuthorPosts

-

August 10, 2021 at 3:07 pm #244619

A ’59 Fastwin was recently given to me as a parts motor but after checking it out, I think it will run again.

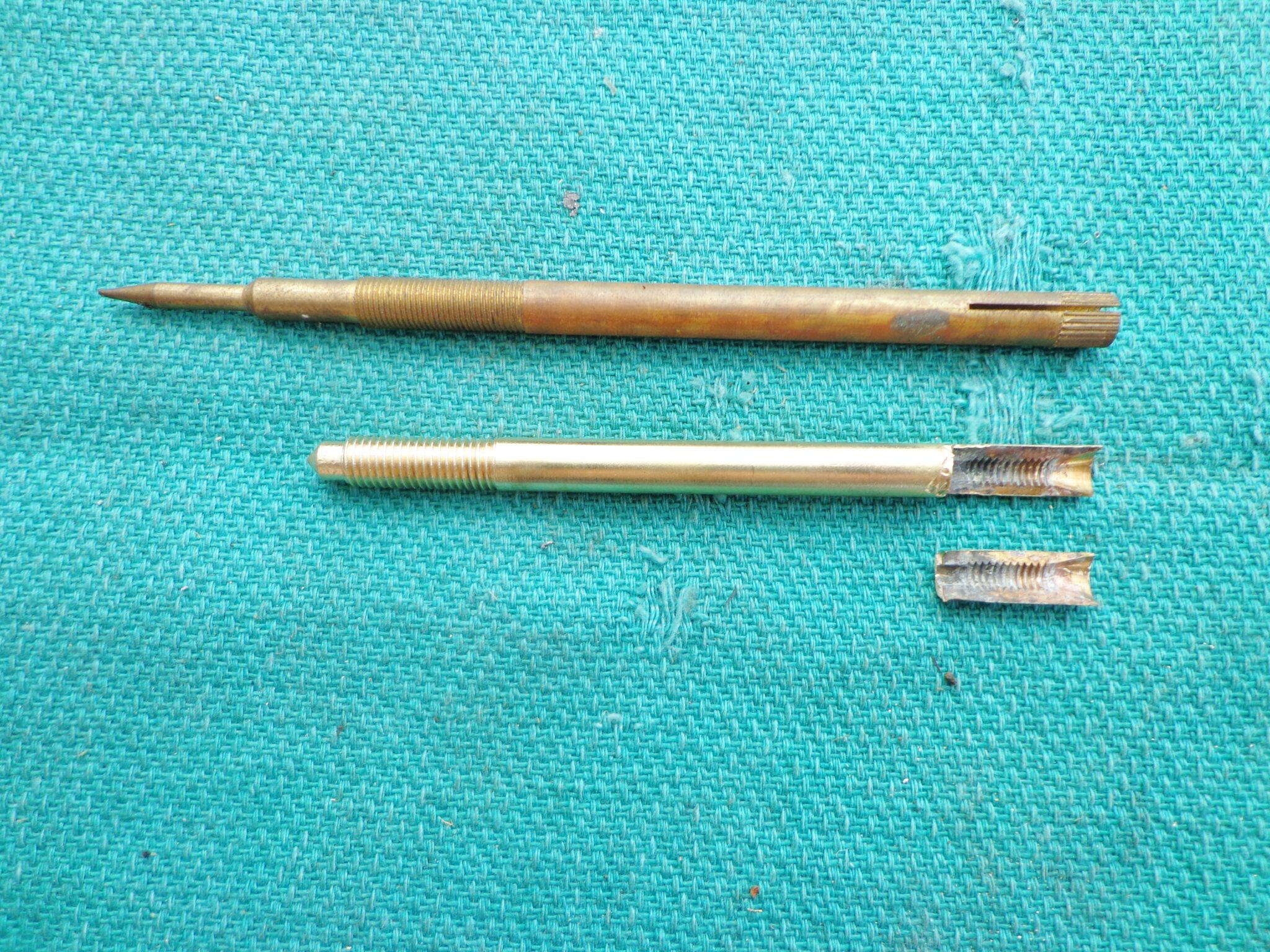

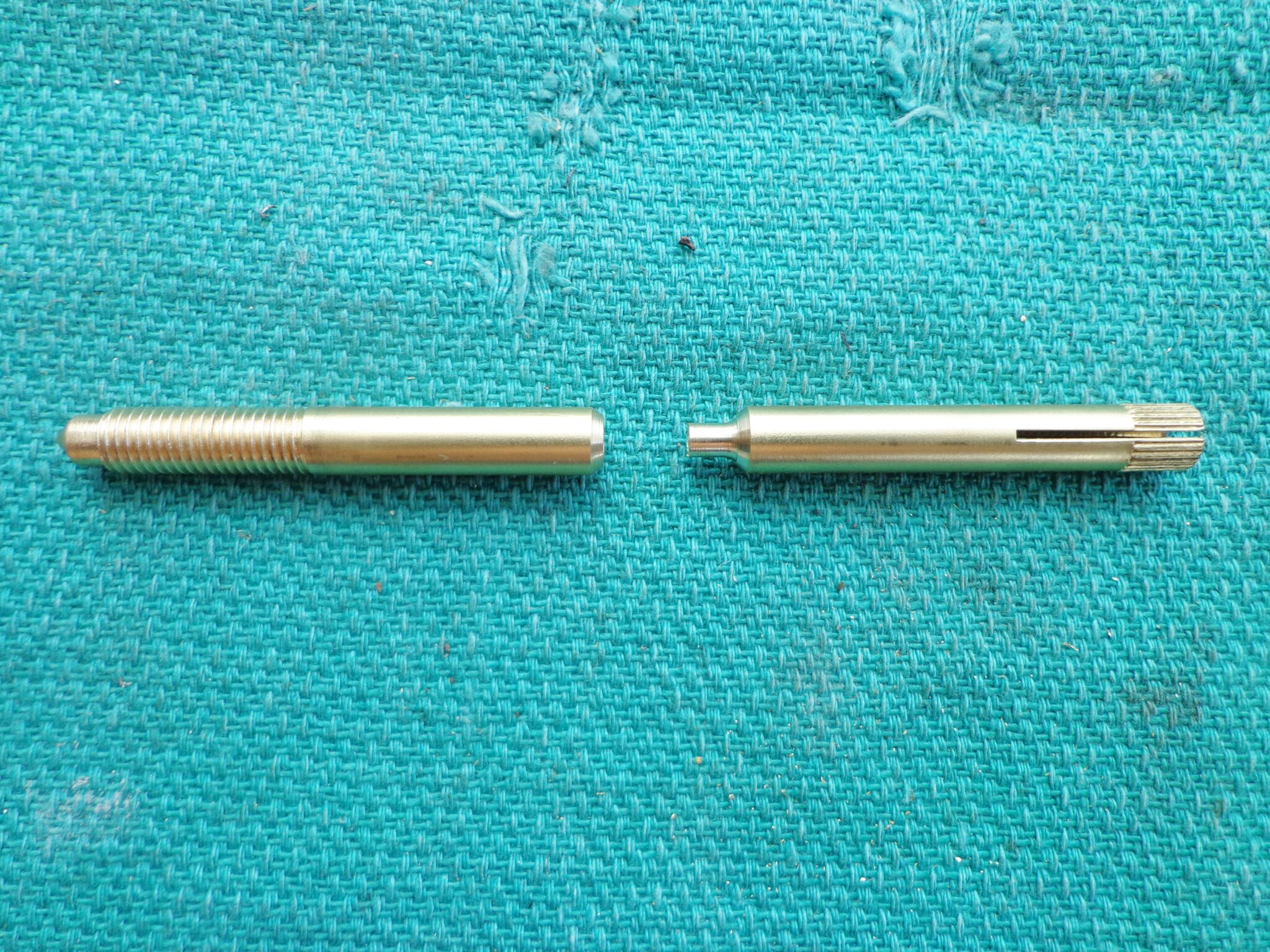

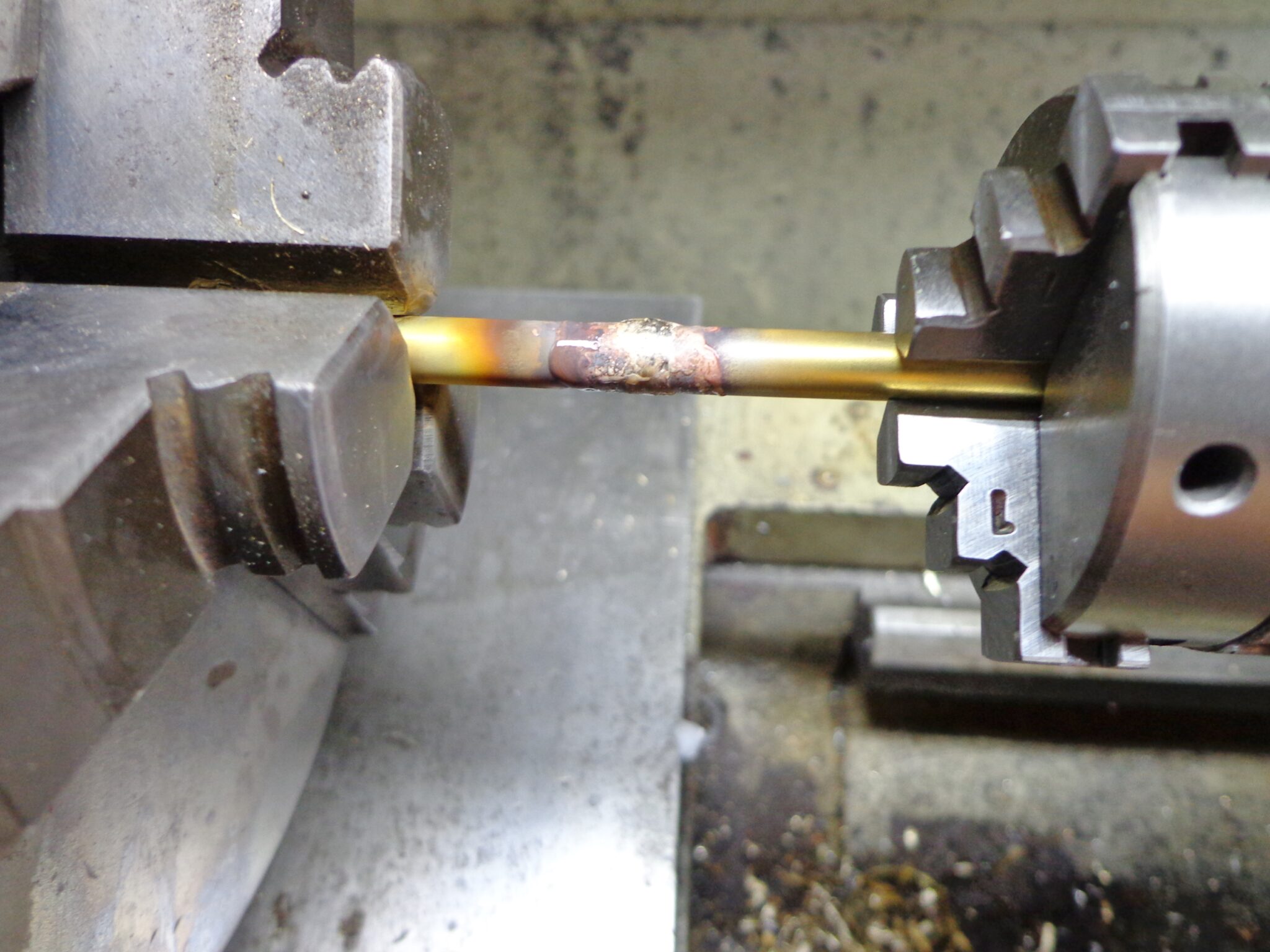

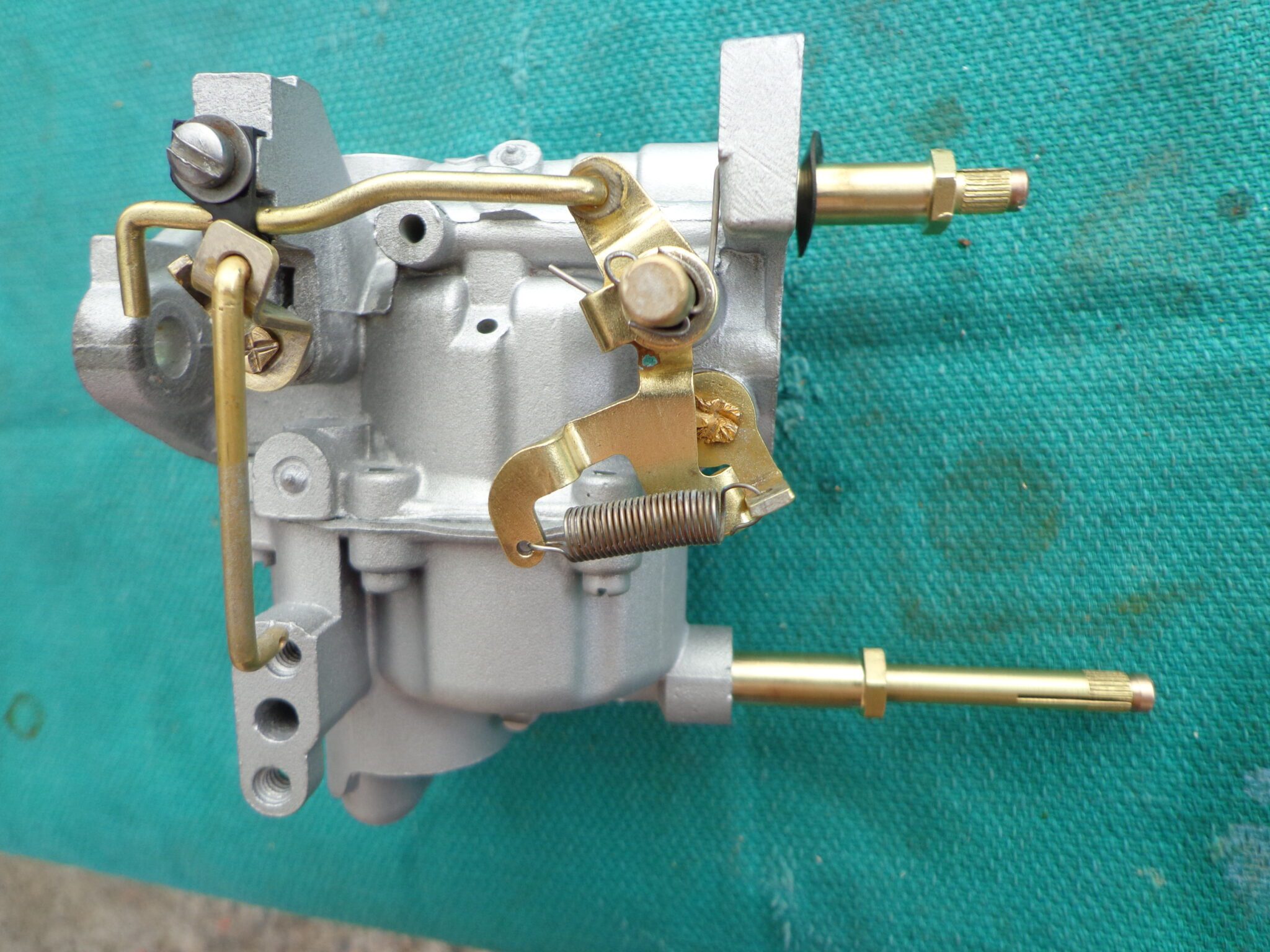

One of the issues with it besides the butterfly valve being stuck open was the high speed mixture needle. The end was corroded thru and broken off. Since I couldn’t find a correct replacement in my stash, I decided to repair it by cutting it and another one and making one out of two. After a little bit of measuring and machining, the two pieces were silver brazed together and then turned to clean up the joint, which is pretty much invisible.

While the lathe was being used, I figured it was also a good time to clean up the tapers on both needles.

Stay tuned, more to come on this project!

August 10, 2021 at 3:44 pm #244629WOW

August 10, 2021 at 4:12 pm #244633Well done Mumbles……….brilliant effort!

Monte NZ

August 10, 2021 at 4:16 pm #244634WOW! great job…. was that a salvaged knurled end or did you have to fabricate it? Tricky fab job with internal taper and straight knurl

Joe B

August 10, 2021 at 5:39 pm #244636That’s incredible – wish I had a lathe and more talent!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."August 10, 2021 at 5:55 pm #244638WOW! great job…. was that a salvaged knurled end or did you have to fabricate it? Tricky fab job with internal taper and straight knurl

Joe B

Thanks guys! The job wasn’t really hard, just a bit time consuming.

joecb: I cut the knurled end off the old needle in my first photo and grafted it onto the good end of the original needle. I have made complete needles from scratch before but only for needles with snap on knobs. This older style with the tapered screw could be made but I would need a slitting saw, which I don’t have. Maybe down the road sometime.

August 10, 2021 at 6:34 pm #244644Great looking jobs Mumbles!

Just for clarification, were the two halves silver soldered,

or brazed together with brazing rod?Prepare to be boarded!

August 10, 2021 at 6:38 pm #244645Silver brazed. It comes in a roll with flux or as a stick from my welding supplier.

August 10, 2021 at 9:54 pm #244713Silver brazed. It comes in a roll with flux or as a stick from my welding supplier.

Interesting, I’ve never used the stuff. My quick search shows it’s popular

with bicycle builders.

Sounds like silver soldering, but not sure

what different alloys there may be between the two.Prepare to be boarded!

August 13, 2021 at 9:51 am #244813Silver alloy solder is better than straight silver/tin when it comes to gap filling. Its major component is copper, which gives it a good ability to bond with brass components..

Make sure you buy the stuff without cadmium — bad for the health.

-

AuthorPosts

- You must be logged in to reply to this topic.