Home › Forum › Ask A Member › KA series crank removal

- This topic has 6 replies, 5 voices, and was last updated 1 year, 10 months ago by

squierka39.

squierka39.

-

AuthorPosts

-

June 9, 2022 at 8:23 am #261202

Goodmorning gentlemen, I’m stuck….or at least my crank is stuck in the block! From what I could make out from my shop manual, the crank should slide out freely but the counterweight seems to be hitting the block. I have attached two photos that might help clear up any lack of wording on my behalf. Am I missing something in my procedure?

Please help me get unstuck.

June 9, 2022 at 8:32 am #261205Not sure on this motor, but some have an external set screw to hold the

crank center main bearing in the correct orientation and position.

On some motors the center main is a slight press fit in the crankcase

and require some heating the crankcase to get the crank out.

Crankshafts aren’t designed for much of an axial “pressing”, so

spacer blocks between the crankshaft webs are some times needed.Prepare to be boarded!

June 9, 2022 at 10:22 am #261208Have you removed the crankcase head?

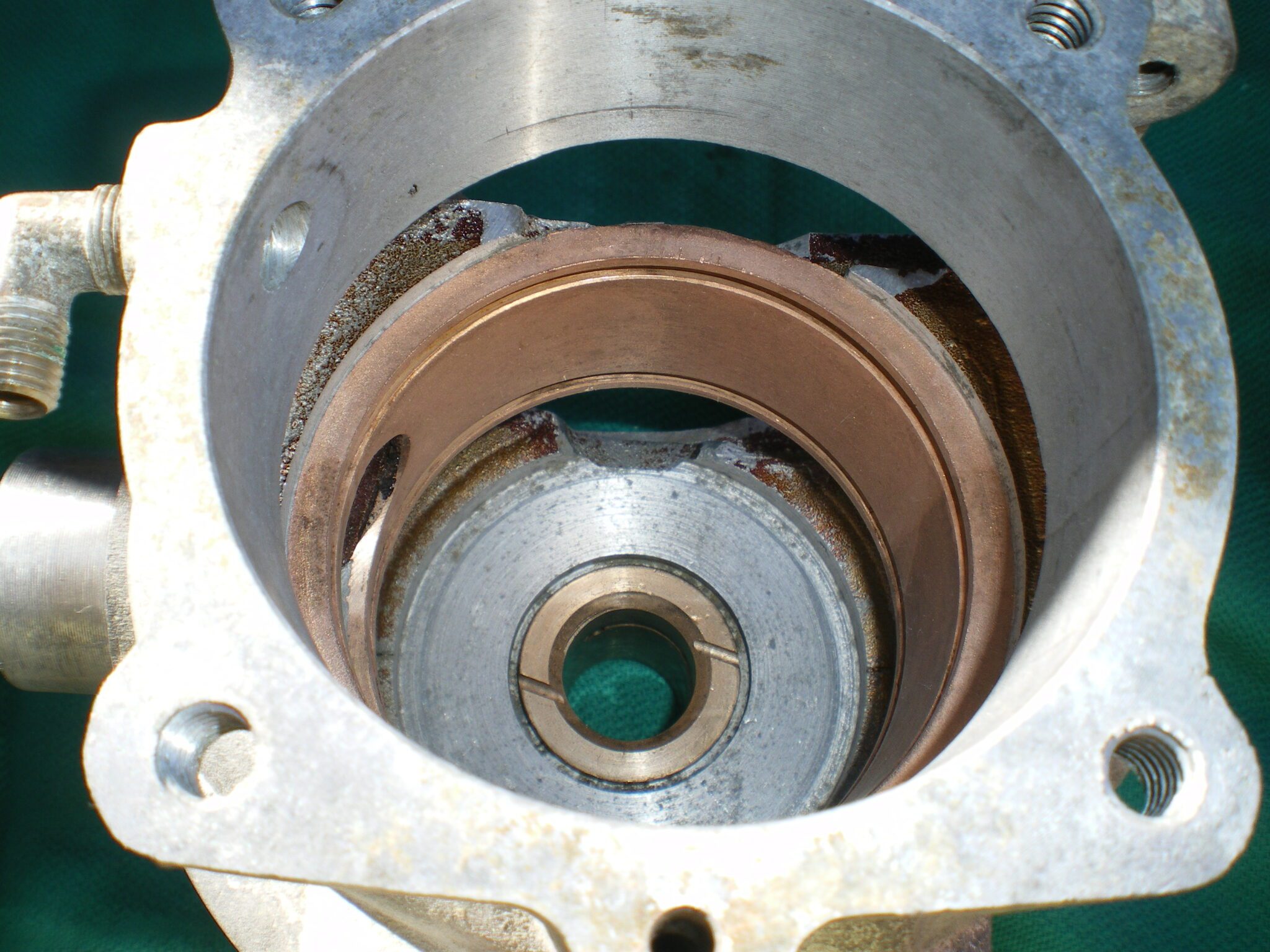

June 9, 2022 at 11:16 am #261210There are two cast iron sealing rings on the cranks large rotary valve and since your motor shows signs of moisture having been in it, they are probably stuck to the crank, just like piston rings stick to cylinder walls from rust. Soaking with your favorite penetrating oil should help break them free.

In this photo you can see the grooves in the large bronze bearing which the sealing rings fit in and why they require an 8:1 fuel mix.

June 9, 2022 at 1:42 pm #261220I see now that the 3rd Edition Johnson repair manual mentions

this type of crankcase.Prepare to be boarded!

June 12, 2022 at 8:38 am #261400Hello again, I finally got around to checking the info you guys supplied…..my motor still has the crank throw with way too tight a fit with the bronze rotor bushing. I tried to tap it through and it was met with too much resistance so I stopped. I was looking at the 10th edition and a much older one for info. and will keep searching. Thanks for all your help.

June 17, 2022 at 8:11 am #261579Gus, the rings that were mentioned above are very tight. Getting the bottom counterweight past them can feel like it’s going to break, but it won’t. You just need to give it a good pull. I’ve taken a few of these apart. Lube it up some and pop it out. There two rings so it will do the same on the second one. There is no other way around it.

-

AuthorPosts

- You must be logged in to reply to this topic.