Home › Forum › Ask A Member › 1929 Johnson A-45 Spark Plug Wires / Coil

- This topic has 25 replies, 8 voices, and was last updated 4 years, 12 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

December 15, 2020 at 1:17 pm #225281

When I finally dug enough tar out of the coil cavity to free the coil,

I noticed one tab on the coil was broke off. Never did find the broken

tab. I presume I broke it as I was digging out the tar.I have 9mm plug wire on order, but in the mean time, I’m

wondering how to install the new plugs wires when they come.

I’m doubtful if one can solder the wires to the coil on the bench,

then work both plug wires into the holes, without stressing

the coil’s secondary connections.It also looks like it may be challenging to solder the plug

wires in place after the coil is in position, especially on

the one with the broken tab.The original remaining tab on the coil did not have a hole

drilled thu it to insert the plug wire through, but was just

soldered to the side.

Just wonder how any of you have installed new plug wires

successfully?Lastly, is it necessary to re-pot the area below the coil again

to prevent arcing, or was the tar more for securing the wires?

I would rather slide some Fish paper under the coil than ever

have to dig tar out again!Prepare to be boarded!

December 16, 2020 at 7:50 am #225335Buccaneeer:

I am at about the same point in a S45. Are you sure that you need 9mm plug wire? I was intending to use 7mm as usual, although the crusty stuff that I took off looked bigger.

I also look forward to the collective wisdom of replacing the tar with something more pleasant.December 16, 2020 at 9:49 am #225337Buccaneeer:

I am at about the same point in a S45. Are you sure that you need 9mm plug wire? I was intending to use 7mm as usual, although the crusty stuff that I took off looked bigger.

I also look forward to the collective wisdom of replacing the tar with something more pleasant.It was mentioned to me to use 9mm, and what came out of the motor appears

to be larger than normal plug wire. That said, you surely could use regular

7 mm plug wire if you wish. I ordered some 9 mm black, woven wire

from Brillman just for aesthetics.Under the plastic / bakelite nuts there were dished washers and some

kind of rubber grommet that compressed the wire tight when the

nut was tightened….. at least I presume that was the idea.

I wonder if O-rings would work? The original rubber grommets

were a gooey mess that came out in a million little pieces.Prepare to be boarded!

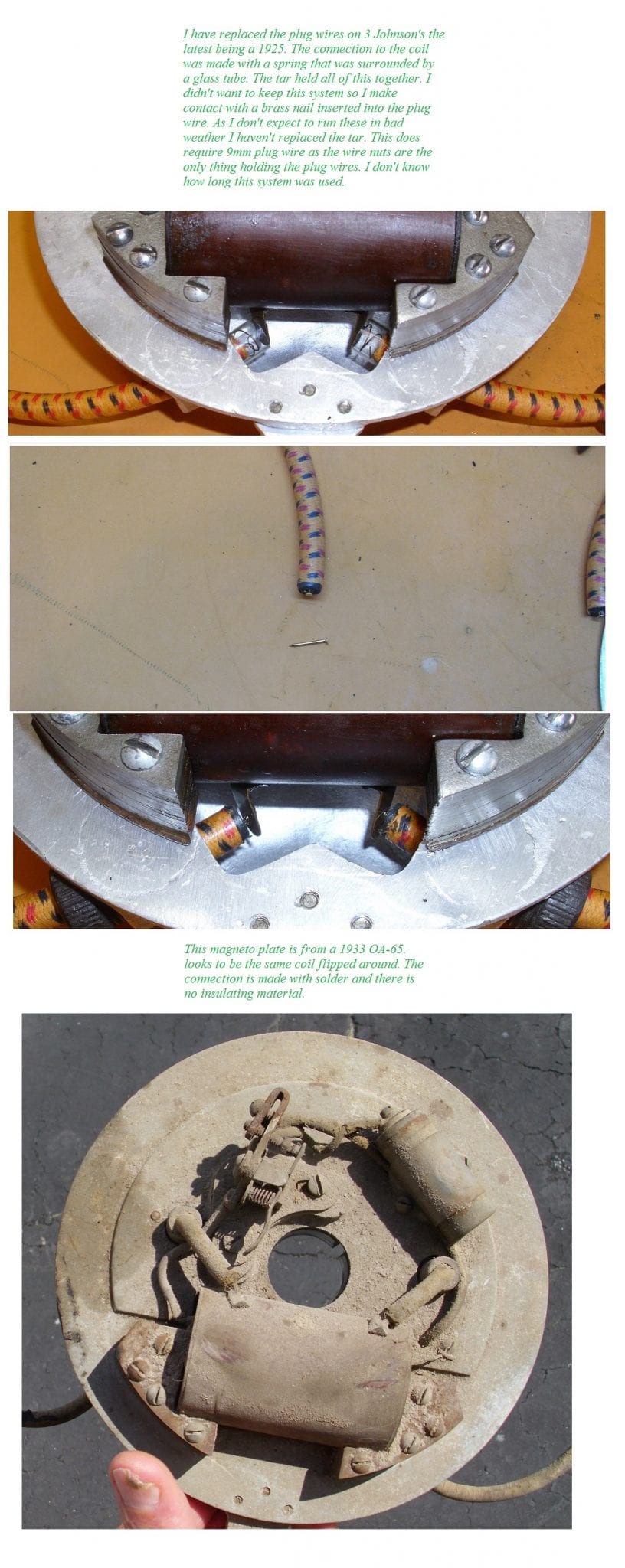

December 16, 2020 at 10:10 am #225338December 16, 2020 at 12:35 pm #225350Tubs, interesting about the glass tubes. They must have quit using the

“tube and spring” affair some time after 1925 and before my A-45

in 1929, as I definitely didn’t dig any glass or springs out of the tar.Was the plug wire on that OA-65 installed before or after the coil

was installed on the mag plate?

Thanks.Prepare to be boarded!

December 16, 2020 at 3:50 pm #225360Buccaneer,

I have repaired coils (with success thus far)that have had the tabs broken off. I’ll try to attach some pictures of the process.

First I cleaned it all up and found the hole in the hard covering. Then, very carefully cut around that hole to find which direction the wire that came out of it ran under the hard covering.

Then expanded the hole in that direction to get more wire, enough to be comfortable working with and gently (!) lifted that wire out. I then soldered an extension onto it, tucked it gently back down so only the new wire was exposed after refilling the hole with epoxy.

I took all the advice about being gentle and real conservative with heat.

I used to have a putty clay like stuff that I’d put around an area to be welded to dissipate heat, but I just used a wet shop towel this time. And gentle air blasts.

GeerJMGP

December 16, 2020 at 4:01 pm #225361Finished product.

It has some liquid electrical goop gobbed on it.JMGP

December 16, 2020 at 4:05 pm #225363Try again with the other two pictures.

GJMGP

December 16, 2020 at 4:06 pm #225365And one more.

JMGP

December 16, 2020 at 4:13 pm #225375And….

If I were to do it again, I’d make tabs with holes in them to protrude from the hard covering, what is it bake lite(?).

Then one could just Thread the stripped spark plug wire and twist it together.

And…..on a tangent here, I’m going to start experimenting with reproducing those oh so hard to find coils!!

Got the idea when I saw a strange looking roll of wire and asked about it. My friend said it’s for making coils.

Anyone ever tried?

I’m thinking a drill and a jig and some Kevlar gloves and some bake lite.

Ha!

GJMGP

-

AuthorPosts

- You must be logged in to reply to this topic.