Home › Forum › Ask A Member › 1936 Evinrude 9017, 16.2 hp, Sportfour Imperial Electric Start

- This topic has 26 replies, 7 voices, and was last updated 4 months, 2 weeks ago by

Tubs.

Tubs.

-

AuthorPosts

-

September 30, 2025 at 9:16 am #300236

I looked at your detailed engine rebuild pictures to see how one might add tension to advance lever. 1-could you put a spring washer under points plate or under points cam? The cam nut would I think dictate tension possibly? 2-Some sort of shim in lever cross shaft tube? 3- another spring washer under other end of cross shaft. I believe you said you already installed one at one end. 4-drill and tap a hole in cross shaft casing and install a tension set screw. I do not know if there would be an access hole for adjustment. Just some thoughts on possible ways.

September 30, 2025 at 11:37 am #300242September 30, 2025 at 11:41 am #300244September 30, 2025 at 2:38 pm #300248I saw your picture of the point plate upside down. That is when I thought that being your regulator was missing pieces, maybe the point plate was off at some point and parts could have been left out. Without a parts diagram, only a guess.

Now that I see your new picture of the underside of the housing with lever, is it possible that there was a control cable hooked up to the lever to control it? I know you said you have a choke lever bracket.

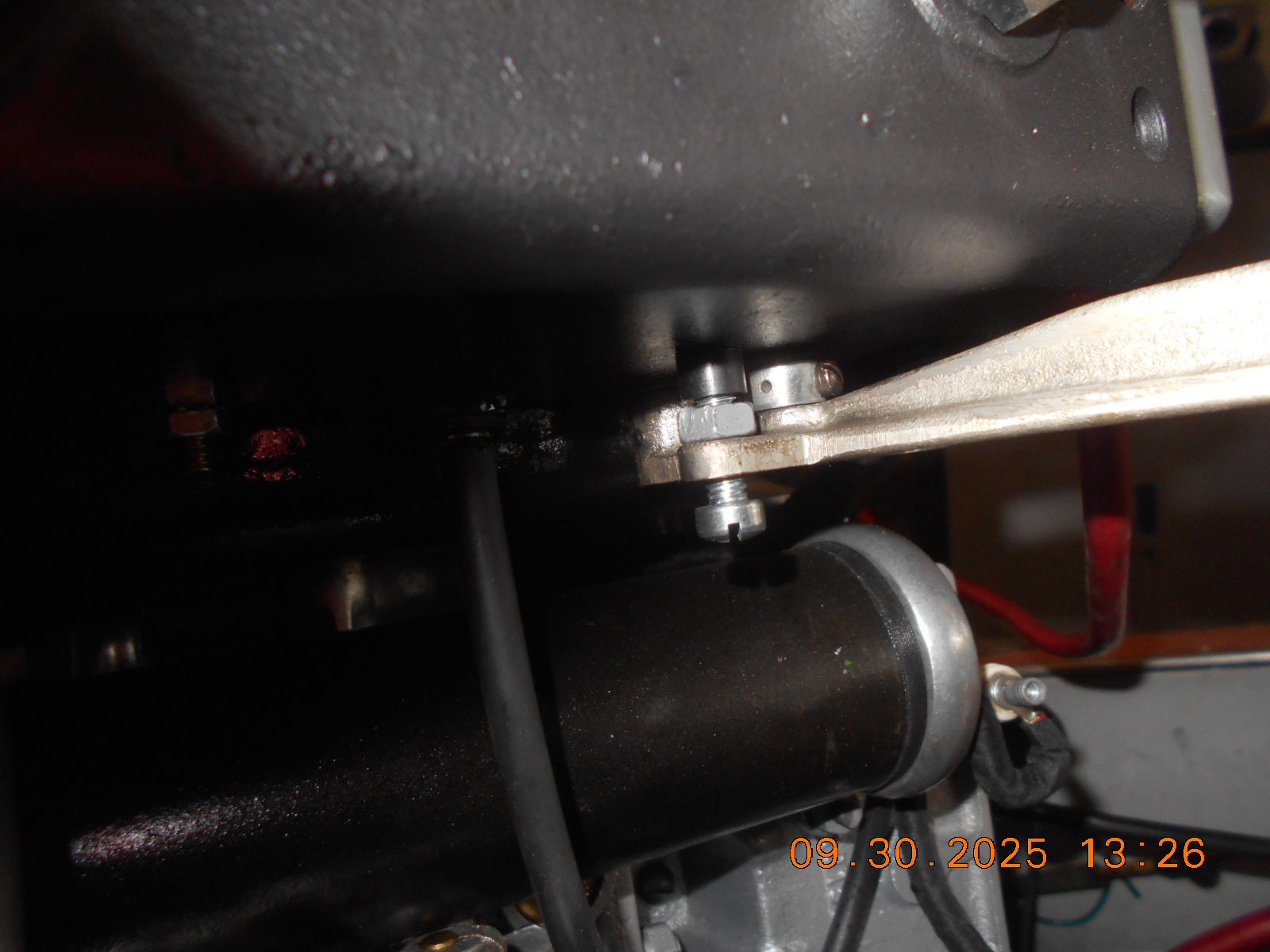

Your idea of maybe a tensioner between the lever and housing could also have been there. A ball bearing inserted in hole in lever applying tension on housing? Just throwing ideas out there.September 30, 2025 at 5:52 pm #300251Gary, The item I have an arrow pointing to, is as you mention,

a swivel nut affair riveted on, to which the inner Bowden cable attaches to.

There’s a 1/4″ hole through the lever about 1″ from the arrow.

Not sure what it was originally for, but it’s now where my tensioner

resides.

Once I got the idea, it only took a few minutes to make up a tensioner.

I drilled and tapped a 1/4″ long piece of 3/8″ Delron, and attached it

to the lever with a 1/4″ bolt and nut.

Turning the nut down forces the Delron piece up against the bottom of

the electrical gear housing.

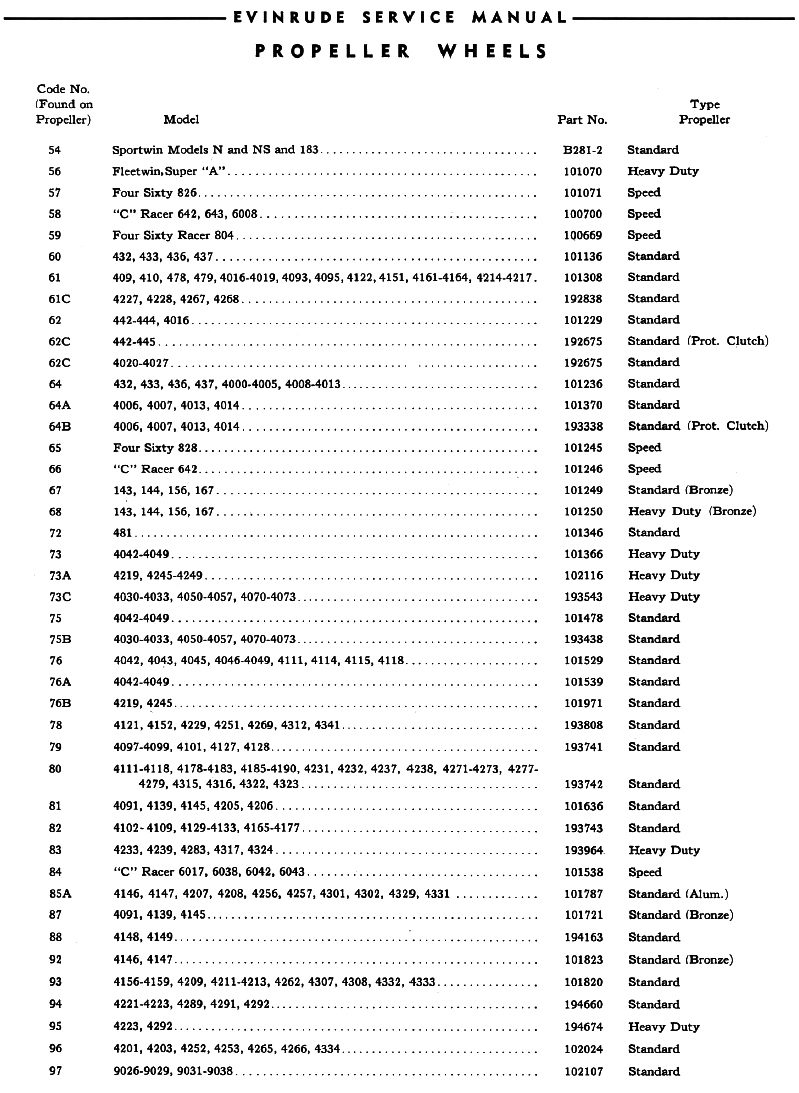

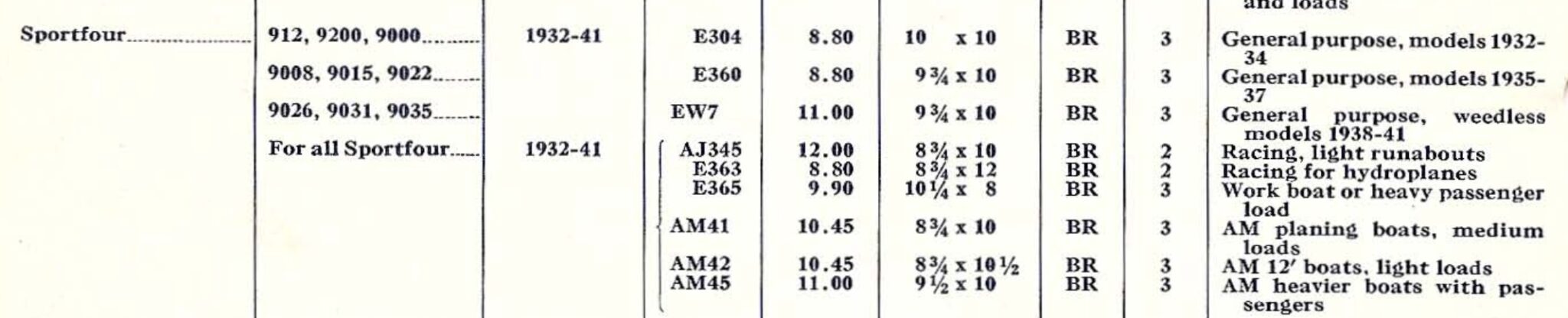

It seems like it will work okay.I looked over the prop situation more, and while I seen one prop stamped 97

before, today I discovered that the other prop is also stamped 97.

Not sure if that’s an OMC prop number, but I find no reference to it on

the Internet.I went to YouTube School of Higher Learning, and came to the conclusion that

both props are basically 10″ diameter x 9″ pitch.

Not sure if that’s what I need for the Crestliner, but it will have to do.

I ended up putting the 1938 Sportfour prop on anyway, as one blade on the

other prop is bent aft about 1/4″ higher than the other blades.Lastly, I reset the ignition timing so now it’s more advanced while the lever is retarded

all the way.

The points break contact when the piston looks to be about 1/8″ before TDC.

Perhaps too much advance, but it took about 15 tries to get it even close

to where I wanted it.

It’s a real pain to try to tighten the points cam lock nut, without

the cam advancing itself while the nut as it’s being tightened.

There’s no good way to hold the cam while tightening the nut. There is

a notch in the topside of the cam, but there’s not enough clearance for any

kind of a spanner wrench.

Would like to see what tool the Evinrude boys used for the job!While out of water, I primed the motor a couple of pumps, and it fired up

for about three seconds, and it sounded like it meant business!

Weather permitting, I hope to retry on the lake soon.Prepare to be boarded!

September 30, 2025 at 6:10 pm #300254September 30, 2025 at 7:19 pm #300257That same Evinrude Service Manual shows the 1936 Sportfour model 9015 (magneto) as having a standard prop code stamped on the prop as #47. Don’t know pitch or dia, or if differences exist between ’36 and ’38 gearcases or RPMs. The #47 prop is also used on ’32-’35 magneto Evin Sportfour and ’35,’37,’38 Electric Start Sportfours and ’34-’35 Elto Sportfour, and ’32-’33 Elto Junior Quad. The #47 and #97 have different Evinrude part numbers.

September 30, 2025 at 9:52 pm #300261Thanks for the data Harry. I found that the prop 97 is listed as 9-3/4″ x 9-3/4″.

I guess for now, I’ll see if advancing the timing gets the old girl to wind up

better. If not, smaller boat, or different prop perhaps!Prepare to be boarded!

September 30, 2025 at 10:11 pm #300262October 1, 2025 at 7:17 am #300266Great job on the lever tensioner. To advance or retard the timing, can you just lengthen or shorten the treaded rod that goes from the lever to the points plate? If so, that looks like you would be able to make adjustments a lot easier.

-

AuthorPosts

- You must be logged in to reply to this topic.