Home › Forum › Ask A Member › 1938 Elto Ace Carb Repair?

- This topic has 27 replies, 7 voices, and was last updated 4 years, 4 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

August 25, 2021 at 6:53 pm #245479

The replacement carb from EBay showed up a couple of days ago.

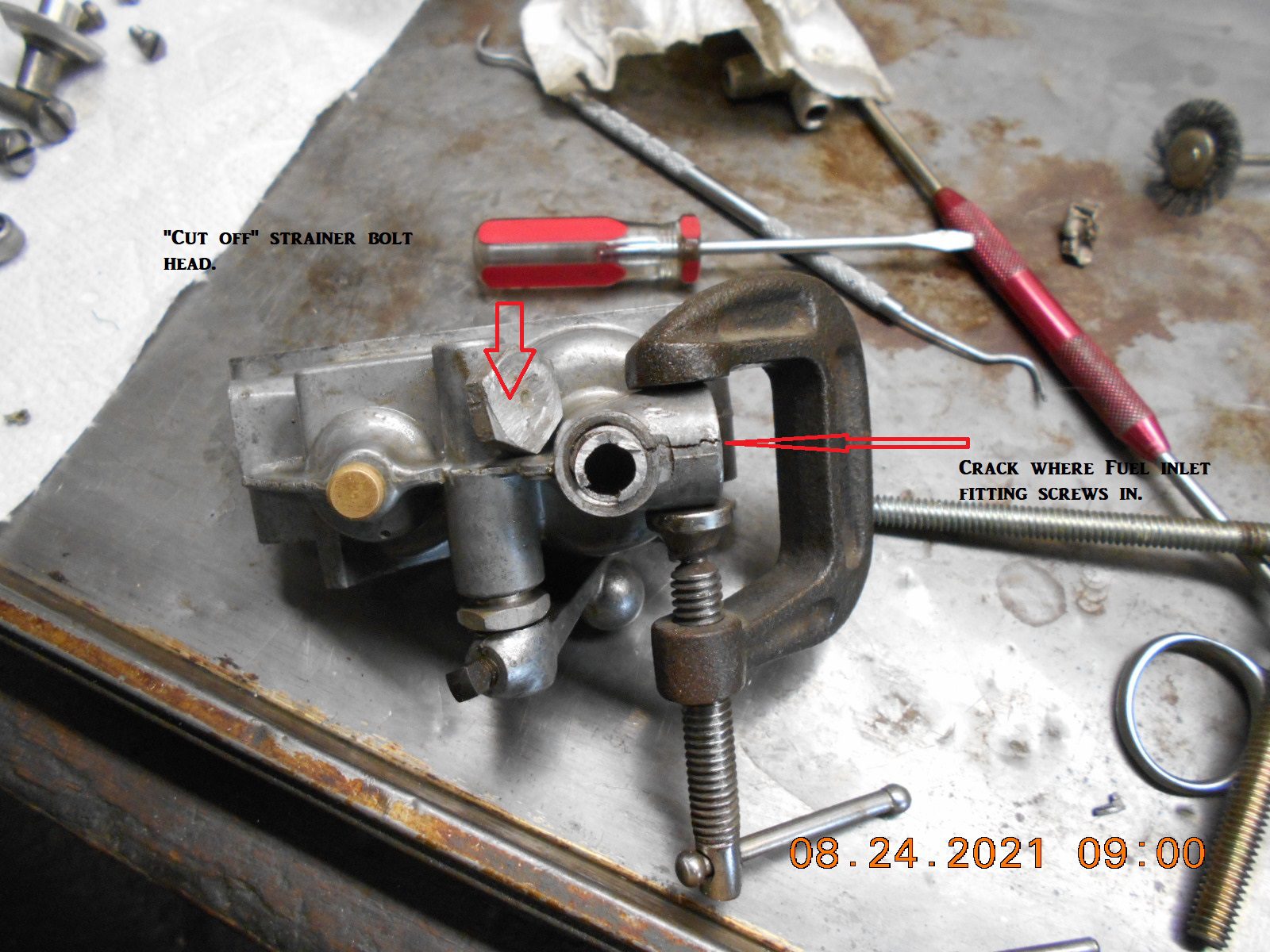

It looked great, but the strainer plug, fuel inlet elbow, nor the adjustment

needle would budge. I took apart what I could, and soaked it overnight

in carb cleaner.

The next morning the said items were still “stuck”, so I proceeded with

penetrating oil, and careful heating with a little propane bottle torch.After a bit I got the strainer plug to move back and forth about 1/4 turn

but no more. About the same time, the gas line “elbow” fitting loosened

up easy, but I noticed a crack in the casting there.I ended up cutting the head of the strainer bolt off with a Dremel.

The strainer bolt was “half” ate away, and there was material “welded”

in the threads, from corrosion or galvanic action perhaps.I was able to collapse the rest of the strainer bolt and got it out.

There’s not much “meat” in the casting between the fuel inlet

and strainer threads where the meet up. Poor design and years

of corrosion probably idled many of these motors.I wasn’t going to try soldering the crack in the casting, and the strainer

hole threads were “iffy” even after cleaning them up with a tap.

Therefore I made 7/16 x 20 bushing to screw into the original strainer hole,

that has a 5/16″ x 24 hole in the center for a new strainer bolt with nice threads,

and still allow the float needle to pass thru okay.The OD of the bushing and the fuel inlet fitting was “doped” up with JB Alumi Weld.

Best thing I could find today. Not sure long term how it resist gasoline, but

I’ve had some regular JB Weld on a “three wheeler” gas tank leak for years.Instead of using the old “elbow’ fitting on the carb inlet, I found a straight fitting

to use, that will make it easier to unplug or rod out if ever needed.I previously put a brass strainer inside the gas tank, so one in the carb will not be needed.

Hope to try it out in a day or two when the JB Weld is completely cured!

Prepare to be boarded!

August 25, 2021 at 9:31 pm #245490Nice fix – hopefully, the JB Weld will hold up.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."August 29, 2021 at 6:13 pm #245710The JB Weld on the replacement carb and it’s repair, had cured for a few days, so decided to try it out.

Looks like success to me!Prepare to be boarded!

August 29, 2021 at 6:21 pm #245712Runs great – glad the fix worked out!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."August 29, 2021 at 9:29 pm #245743

Way to keep em going. I know I have had

a couple dozen of those carburetors over the

years and have never seen either problem that

you had. I have a 1 hp. project motor. I was

planning on doing it this winter. Now you

have got me worrying about what I might find

if I do start on it.

TubsA "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 29, 2021 at 9:40 pm #245744Nice job there captain Buccaneer! I wonder if that carb part could be made on a 3D printer? Once there is a program a CNC could whip one out in no time. What fun is that you might ask!!! Thanks for sharing with us.

dale

August 29, 2021 at 9:42 pm #245745All I can say, if the carb fittings are stuck, avoid putting heat to it, soak

it plenty, and be patient. The castings are pretty thin around the fuel

inlet and strainer screen junction, and evidently like to corrode there

as well.Prepare to be boarded!

August 29, 2021 at 9:45 pm #245746Nice job there captain Buccaneer! I wonder if that carb part could be made on a 3D printer? Once there is a program a CNC could whip one out in no time. What fun is that you might ask!!! Thanks for sharing with us.

dale

Not that my machining skill are up to the task, but I’d rather try to make one out of a block of

aluminum on the milling machine. Not sure I’d be happy with one of those printers

taking all night to make a part, then have it buggered up, lol.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.