Home › Forum › Ask A Member › 1938 Sportfour Bowden Cable

- This topic has 22 replies, 6 voices, and was last updated 3 years, 4 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

September 8, 2022 at 5:51 pm #265727

I ordered some “universal” lawnmower Bowden cable in hopes

of re-routing the new cable correctly, from the tiller handle,

“underneath” the front cover, as from the factory, instead of “through” it, like

a previous owner did.The cable going under the cover needs to take a rather torturous “S” turn.

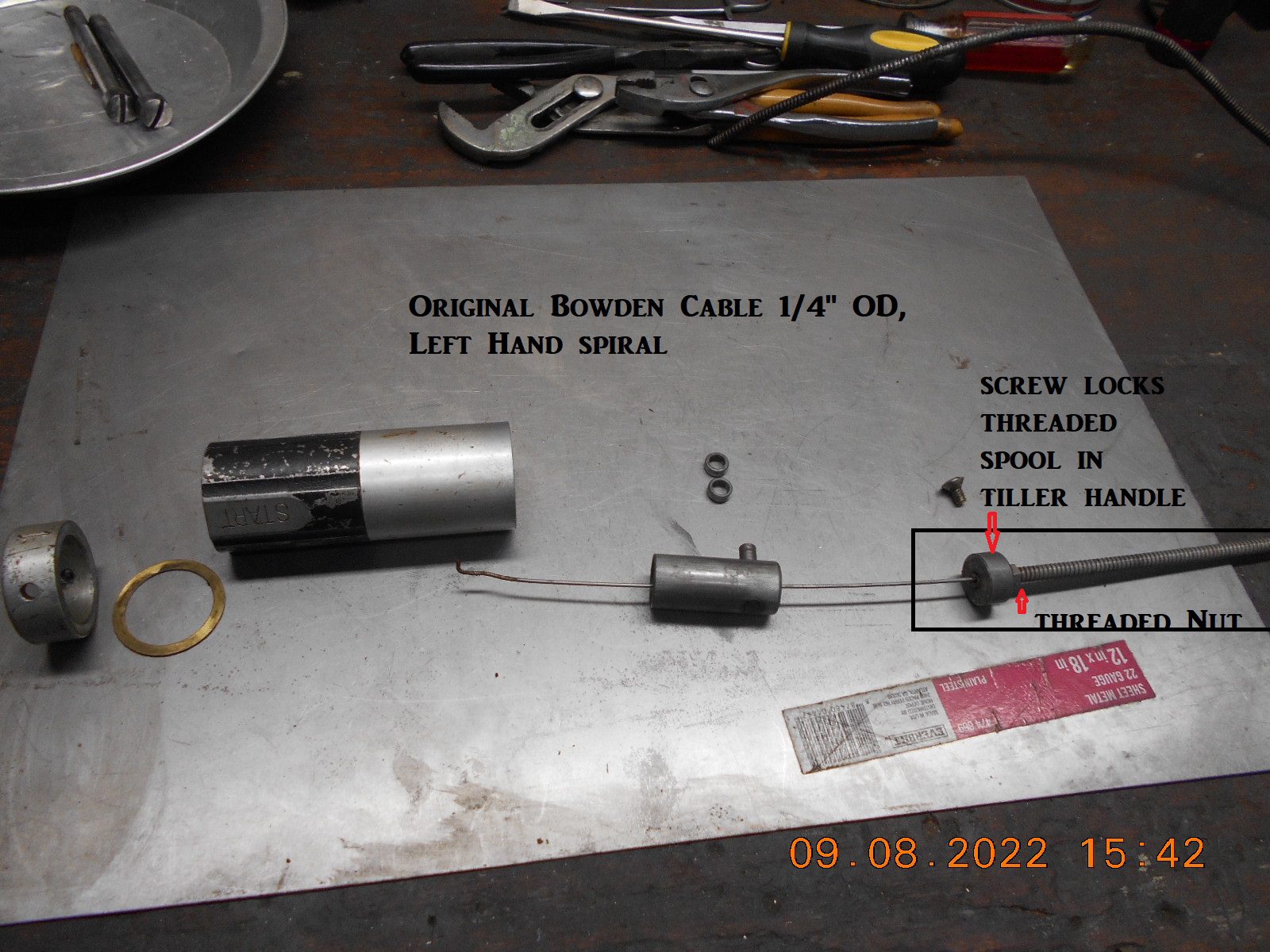

The old cable sheath was 1/4″ OD, Left hand spiral wound.The new cable sheath OD is 3/16″, so I thought, “good”, maybe it will take

the “S” turn easier. Once I got the old cable out of the tiller handle,

it didn’t take long before I see I had troubles.

There’s a threaded spool that holds the cable in place inside of the tiller handle,

via a bolt from the outside, and there’s a threaded nut behind the spool as well.

Not only is the new Bowden cable too small for the threaded pieces, the new

cable is a Right Hand spiral.

I thought about machining a new spool, but the tap needed would be 3/16″ x 18 TPI,

or so, and the cable is not a “pointy” thread profile either. I don’t believe said tap exist

anyway.Just wondering if anyone has run into this problem and had a “work around”?

I could always look for the correct size Bowden cable, but they don’t always

list the specs for the cables, and of course the bigger cable is going to be

harder to make the “S” turn.

Thanks.Prepare to be boarded!

September 8, 2022 at 7:07 pm #265741Anonymous

September 8, 2022 at 9:09 pm #265748Steve, I believe I did check there a while back, and just looked again.

It looks like all of their cables are plastic coated sheaths.Prepare to be boarded!

September 8, 2022 at 10:46 pm #265754Buc,

Could you weld, solder or epoxy a short section of the original cable sheath to the end of the new sheath? Another thought would be to build up the new sheath od with solder and cut the thread into that soldered section.

Steve

September 9, 2022 at 9:14 am #265763Buc,

Could you weld, solder or epoxy a short section of the original cable sheath to the end of the new sheath? Another thought would be to build up the new sheath od with solder and cut the thread into that soldered section.

Steve

Steve, your new / old cable union idea has possibilities.

The solder build-up and threading idea might work, but

the original threaded spool and nut are a left hand spiral / thread.

I was also thinking about some kind of compression spool / collet

type of affair, but not sure what it would look like yet!Thanks.

Prepare to be boarded!

September 9, 2022 at 10:20 am #265764Buc,

I have some other ideas as I’m working on the same sort of issue with a speedifour. It would be easier to explain on the phone.

Steve 218-310-8862

September 9, 2022 at 11:20 am #265767

I learned that on a 1938 Fleetwin. I could never

find a source for anything other than the smaller

cable like you have found.

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

September 9, 2022 at 4:33 pm #265781Today was a lesson in futility.

I tried routing the smaller diameter, more flexible Bowden cable

underneath the front cover in the only way I could “guess” it

was originally, and it failed miserably.

I’m guessing the last guy drilled the hole in the front cover out

of frustration.

I ended up using the new cable, and ended up shortening it a couple

of times, routing it back through the front cover.

It’s a real PITA trying to get the cable hooked up to the carb

with the heavy front cover hanging on the cable.To anchor the smaller Bowden cable in the tiller handle, threaded spool piece,

I found that a simple Derlin plug in the bolt hole (that positions the anchor spool

in it’s proper place inside the tiller handle) worked quite nicely. It squishes some

forming around the spiral cable. For good luck, I put some “Seal All” epoxy

around each end of the spool piece where the cable goes through.

At least this way, the original pieces can be used again for the proper size cable.I put new spark plugs in it and am going to call it “Good” until next year when

I try it out on the lake again.

I’d like to find some photos of an original routed cable this winter to see how they did it,

then maybe try re-routing a correct cable in the spring. Right now, I’m sick of

looking at it, lol.Aircraft Spruce, an online site, has some larger Bowden cable, but it doesn’t

say if it’s a “left hand” spiral like the original, needed to work with the anchor spool

and nut. The specs says their cable has a 6″ bending radius.

I see no way to accommodate that large of a radius under the cover.Prepare to be boarded!

September 9, 2022 at 10:58 pm #265794Here is how my ’38 Sportfour is routed, works good

. You might try Roger Melugin (kentucky?). I think he was the guy who reproduced some of that cable once. Or try Doug Penn for a used piece.

-

This reply was modified 3 years, 4 months ago by

HARRY D. NICHOLSON.

-

This reply was modified 3 years, 4 months ago by

HARRY D. NICHOLSON.

September 10, 2022 at 9:44 am #265805Harry, your photo shows the exact route I tried with the new cable.

I suspect the trouble lies in the two sharp bends under the cover.

If you ever pull your motor’s front cover off, a photo of what the cable

looks like there would be great.

Thanks for your help.Prepare to be boarded!

-

This reply was modified 3 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.