Home › Forum › Ask A Member › 1939 1/2hp Cub Barrel Test.

- This topic has 5 replies, 4 voices, and was last updated 9 months, 3 weeks ago by

Tubs.

Tubs.

-

AuthorPosts

-

April 29, 2025 at 11:49 am #295955

Finely getting some weather to do a little tank testing. I went through this motor this winter and it ran out of the water. The real test for these is – in the water – with the prop on. From the looks of the motor when I got it I thought the odds were more likely that it wouldn’t. Compression is 70lbs. Not great, but better that 60 or 65. Oh – check out the dent in the top right-hand side of the gas tank where “some dumb ass” dropped it right after it was painted. Video link – https://youtu.be/_gicwMuUQMk

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

April 29, 2025 at 1:30 pm #295957Great job Tubs!

I feel your pain about the “dumb ass”.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

April 29, 2025 at 3:54 pm #295960You know you can heat up the tank joint and split it into two pieces. Tap out the dents and then resolder the two haves back together again. Make sure the inside of the tank has been washed with Dawn soap several times to get rid of the fumes.

April 29, 2025 at 10:16 pm #295964

I’ve done that. I struggle getting them back together. Propane torch is too hot and the soldering iron I have isn’t hot enough. I’m restoring the tool they used to do it originally. I’m going to see if I can learn to do it that way.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

April 30, 2025 at 2:06 pm #295985Tubs, great job!

You brought it back from the dead to become a really strong runner.

It’s a tricky motor with that tiny cylinder bore to get enough compression to turn the prop in the water. It was really cranking in the bucket. What was the state of the coil and points when you got it?

Is it a Maine candidate? I’m already praying for a dry summer.

Bob DApril 30, 2025 at 11:10 pm #296007

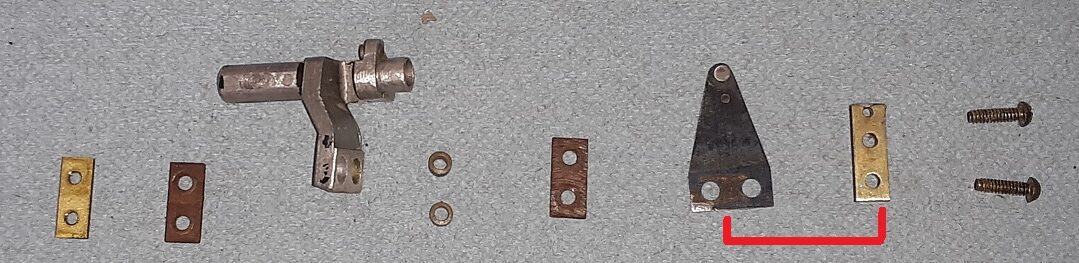

Dittos Bob on the dry weather but I understand you’ve been getting quite a bit of rain up there. Its on the Maine list but we are planning a trip to Wisconsin Memorial Day weekend so, weather permitting, its going to be on a boat for a little bit. Its the original coil. It tested good on a Merc-o-Tronic. Motor seems to run well. I ran it for over two hours to see if any issues would pop up. I think its good to go. Points are the same as the Pre. WW-II Pals, Scout, Ranger, the 1hp Johnson’s, and possibly others, so they are easy to come by. They were fine in this motor but this style of points loose continuity when they sit for a long time, between the brass bar, that the wire connects to, and the contact that moves. You won’t have a spark. Most people think the coil is bad but once you take them apart and clean them, the spark returns.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.