Home › Forum › Ask A Member › 1940 Johnson A-10 Ignition

- This topic has 2 replies, 2 voices, and was last updated 10 years, 5 months ago by

cajuncook1.

-

AuthorPosts

-

September 15, 2015 at 12:47 am #2539

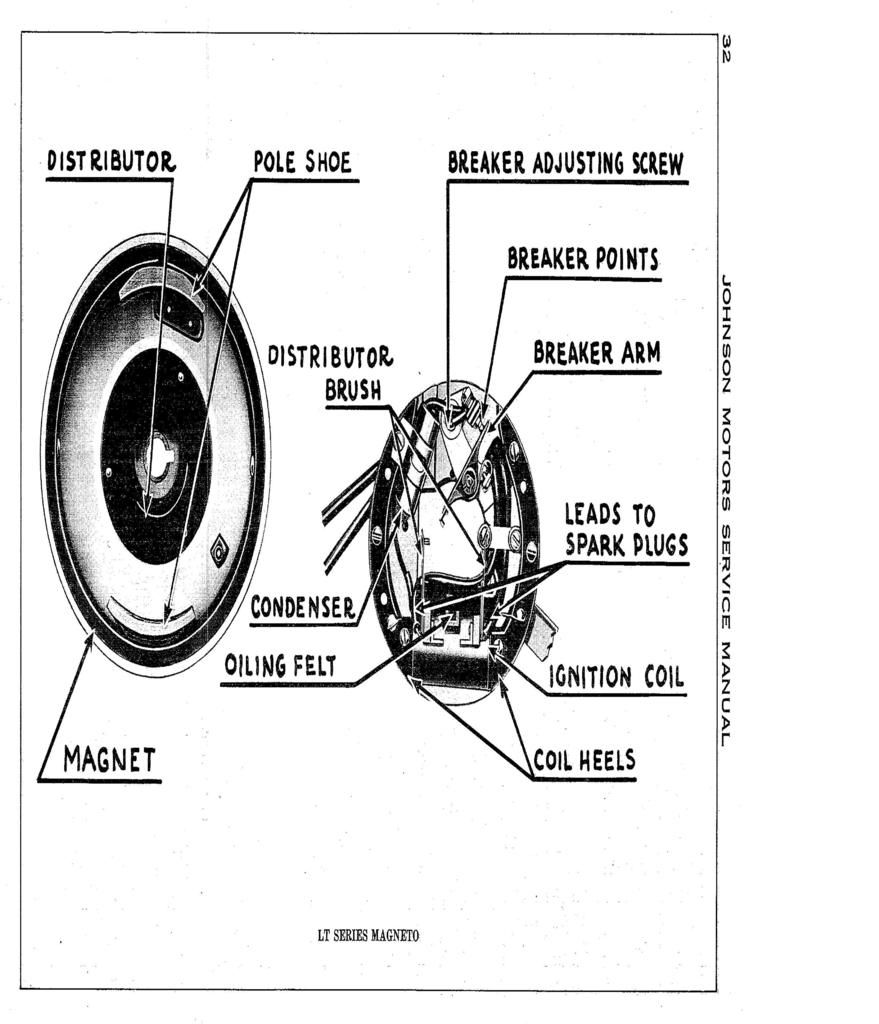

Well guys, I finally got my 1940 Johnson AT-10 5hp unstuck. Bought it as a parts motor because you never know what ‘s going on inside when it is stuck…a gamble at times. Hopefully this little motor pays off and runs again. I looked on YouTube and only a video or 2 of this type motor was found. Are they not a popular motor or they just difficult to revive due to limited available resources to be had? Anyway, I got one so I am going to try and revive it.I was able to get to the ignition plate and found it in pretty decent shape. Now, I have never evaluated a ignition plate of this type. It has one coil, set of points and condenser to supply spark to both high tension leads. After reviewing the Johnson 3rd edition manual, I see that bakelite covering has distributor brushes to prevent spark from being delivered to both upper and lower spark plug leads at the same time. Apparently, if I understand correctly, spark is distributed to both distributor brushes but the metal strip found on the flywheel hub grounds one so only the cylinder at TDC gets the spark.

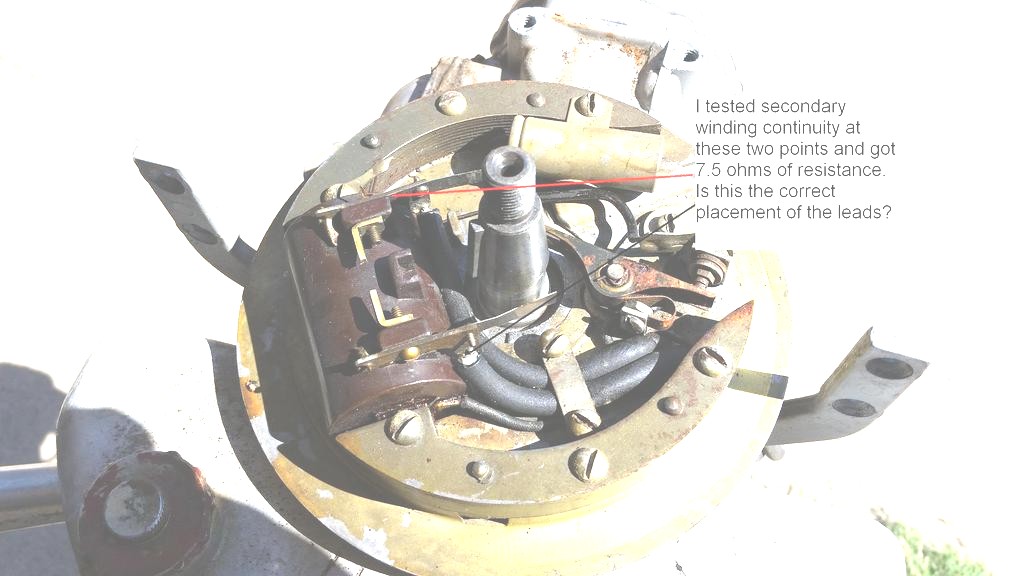

I think the coil is good, the secondary winds ohm out at 7.5 ohms of resistance with a multi-meter. Please see in the diagram below if I place the leads in the appropriate positions. I will clean the magneto, points, and distributor brushes(gently). Hopefully after I set the points, I will be good to go. I do not have the special tool to adjust and set the brushes, so I have to hope they are in proper alignment. If someone has another way of accomplishing the adjustment of the distributor brushes, please let me know.

Thanks for your opinion or advice.

cajuncook1

September 15, 2015 at 1:25 am #23894September 15, 2015 at 3:36 pm #23921

Well, I removed and clean the points. Set them to 0.02 inches. It is kind of nice only having to set one points for both cylinders. Cleaned contact area where I could. Gently cleaned the distributor brushes and clean the distributor disk on the flywheel as well. I saw no cracks in the distributor disk, so it looks like there should be no issues with shorting.Well, nice fat blue sparks on the upper and lower high tension spark plug leads with an open air gap tester set at 1/4 inch. The true test whether the distributor brushes are correctly set is when I get the motor started and there is no back firing at low speeds. I believe that would indicate firing is taking place at the same time on both cylinders instead of spark being grounded when the opposite piston is not at TDC.

Compression is a little low at 62psi at the top and 60psi at the bottom.

I am going to humor this for the time being, because the power head was locked up, so I will assume at this point the rings may be carboned up and not sealing well. Hopefully if I get this motor running and add some Seafoam to the fuel oil mix, it will loosening the rings.

I will keep ya posted.

Cheers,

David T.

-

AuthorPosts

- You must be logged in to reply to this topic.