Home › Forum › Ask A Member › 1941 Johnson MS 20

- This topic has 7 replies, 6 voices, and was last updated 5 years, 9 months ago by

Joshua Byrd.

-

AuthorPosts

-

May 2, 2020 at 12:30 am #201696

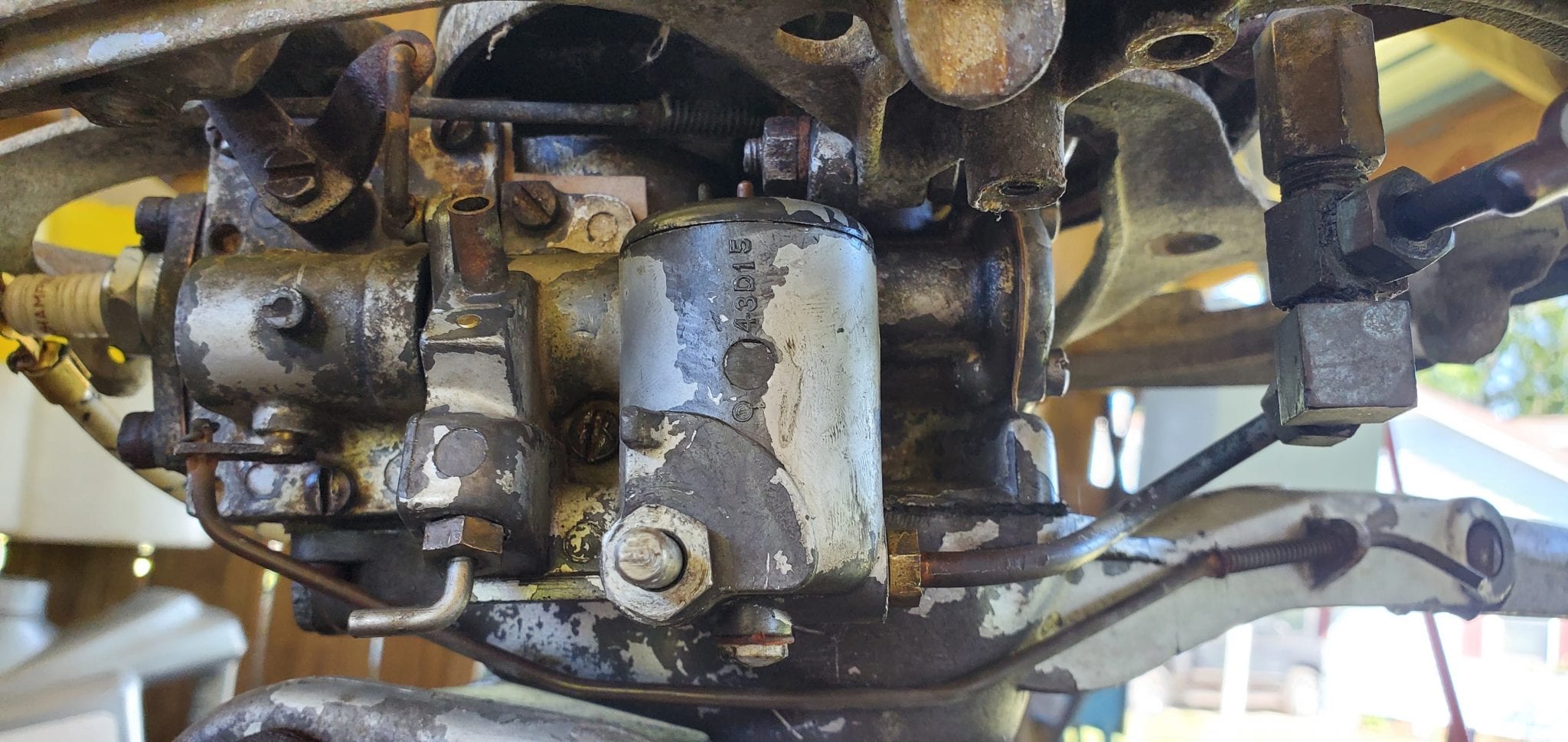

Ive got a old 1941 Johnson MS 20 Im working on. Gone through the ignition and I have a good spark at the plug. Cleaned the carb installed a fresh sealed cork float but the high and low speed needle packings were completely shot. I have been able to get a old parts catalog but I havent been able to find anything as far as servicing the carb. Where could I find or get some leather packings for the high and low speed needle as trying to use rubber packing doesnt seem to be working to well and what are the initial settings for setting the high and low speed needles. Ive been able to find information on the HS 20s but that carb doesnt look like this one and this one doesnt have a primer instead it just has the choke. Also any other information on this motor would be greatly appreciated.

May 2, 2020 at 7:47 am #201715Is your carb like this MD38? I went thru this one, but don’t really remember a packing,

but perhaps there was.

It’s hard to make small leather washers with punches, but that’s always an option

to try to make your own.

I was taught a trick back in the 70’s, when in a pinch, use common string,

wrap it around the needle, tighten the packing nut, and you’re mowing

lawn again!Prepare to be boarded!

May 2, 2020 at 9:36 am #201729.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

May 2, 2020 at 4:23 pm #201766It looks similar to that. I’ll attach a picture of it mounted up.

-

This reply was modified 5 years, 9 months ago by

Mumbles.

Mumbles.

May 2, 2020 at 8:37 pm #201793o rings for packing work.

May 3, 2020 at 11:41 am #201834I’ve heard of some using valve stem packing. When I’ve looked into it all I found was 3/32″ dia. Not sure if that’s too thick.

KirkMay 3, 2020 at 7:30 pm #201928I use Waxed Dental Floss

May 4, 2020 at 12:37 am #201946Ok got a couple more questions concerning this motor.

1. The wire from the coil to the spark suppressor had broken off the spark suppressor and I’m unsure of where it goes. It looks like it should be soildered to the back side of the suppressor. But I have nothing else to look at as a reference and I don’t have a picture on my phone. I have to get that tomorrow.

2. The wriggle pump I’ve seen a picture some where on here that shows where you should have contact. I have contact everywhere except 1 spot. Is there anyone making these rubber pieces for the pump? -

This reply was modified 5 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.