Home › Forum › Ask A Member › 1948 evinrude 3.3 sportwin specs/help

- This topic has 16 replies, 7 voices, and was last updated 9 years, 3 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

April 22, 2015 at 1:21 pm #14488

Bob, I received my 3.3 Sportwin as a basket of parts with the pistons out.

After many queries, study of literature, etc., I installed the pistons, but

still didn’t feel 100% certain there were in correct. The longest I ever got

it to run was about 30 seconds, then went downhill from there.

I then queried different owners to see if their piston’s 90 deg. step

was on the port or starboard side as they looked in, or probed in the

spark plug hole. Of course I got two different answers! Galerider was

recently the "third", and deciding vote. "Steep step" on the port side.

So if yours isn’t the same, one of us still has problems, ha, ha.

I determined from Galerider that my pistons are in correct.

Think I’ll re-visit the low speed adjustment on the carb and make sure the

air shutter is in the correct position for starting.

Good Luck, BuccaneerPrepare to be boarded!

May 20, 2015 at 7:46 pm #16540Hello,

First post here. Thank you for posting this. I just picked up a 3.3 sportwin for $80. Runs good. Had a missing glass carb sediment bowl. Thanks to your diagrams with part numbers I found one on eBay.

My lower unit is also seeping gear oil. I am looking for a shaft seal but the part number in this diagram doesn’t seem to yield any results. Is there perhaps a cross reference part number that may work? Also does the shaft seal come off from the prop end or do I have to take the whole lower unit apart?

October 14, 2016 at 3:21 am #45828This is a nice forum!

Went through my entire carb and fuel system on my 1951 Evinrude 4423 3.3 HP.

Cleaned out Carb, compressed air , Etc.

Replaced rubber seals etc.

Replaced old cork float with Merc retro fit.I have gotten the carb to run the motor OK.

But, I can not get the Carb to not flood the engine at STOP. And not to leak fuel at one spot.There is a tiny hole under the Carb’s output hole after the venturi. Below the gasket. Where the Carb mounts to the motor.

I have no idea what this tiny hole is for. Other than for making the Carb leak.Why do I have fuel dripping out of this hole?

I have set the float all the way to the bottom of the bowl. So that there is barely enough movement to let fuel in before the float rises and shuts off flow.

And fuel still leaks out from behind the Carb via that tiny little hole under the sealing gasket.Please help. Thank you, thank you thank you!

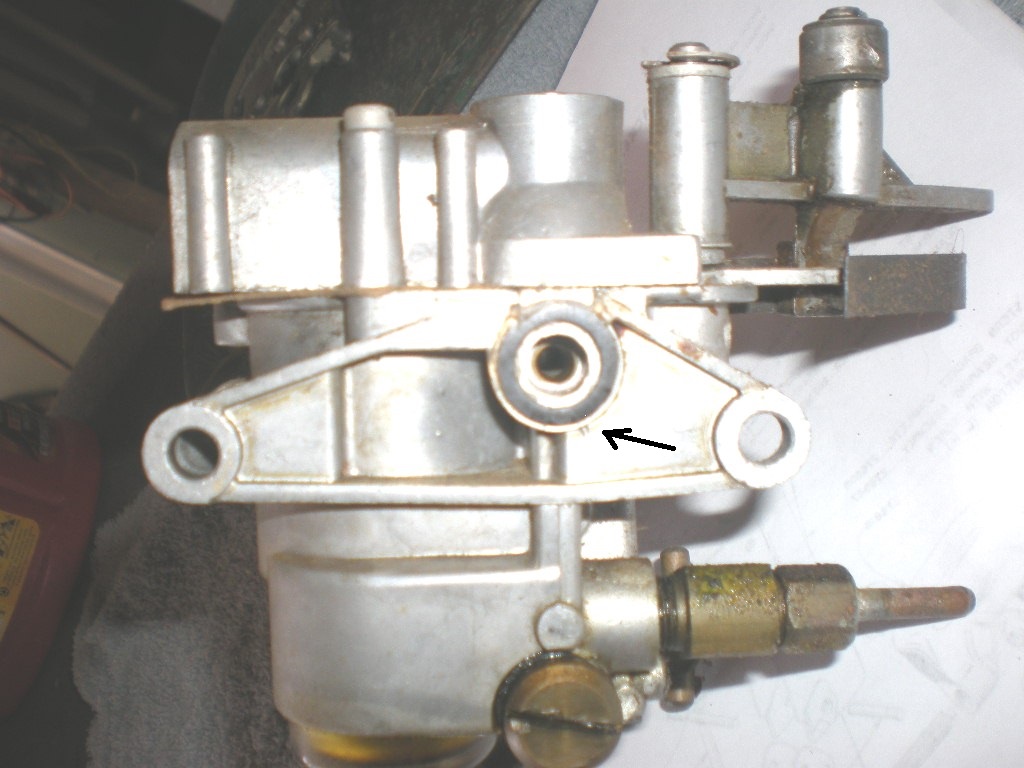

October 14, 2016 at 2:03 pm #45835SportwinDude,

Is this the tiny hole you’re talking about that’s leaking gas?

I took this photo when I had my carb off. The outboard is

now together so I can’t inspect the carb further.

I’m not sure what the hole is for, but I gotta think that your

float and needle is not actually doing it’s job.

Did you try blowing thru the fuel inlet with the carb inverted,

and hence float needle shut, to see if it’s sealing?

Did you perhaps blow any of the internal rubber parts across

the garage when using compressed air? (I’m guilty of that on

more than one occasion!)Prepare to be boarded!

October 14, 2016 at 3:40 pm #45838Hi John

When the dial on the front is turned to "off" the lever inside the cover should close the air vent and pull up on the float pin to stop gas from entering the carburator. If it still leaks, you can try lapping the inlet needle to it’s carburator seat. The other solution would be to shut off the fuel at the fuel line shut off and run the carburetor dry.This would require you fog the motor with fogging oil for storage. When stored, the speed control should be in the STOP position to ensure the air shutter on the side of the cylinders is closed to keep moisture away from the piston rings.

I hope this helps

October 27, 2016 at 6:00 pm #46575

October 27, 2016 at 6:00 pm #46575Gary, Bucc,

Thanks for the help!

I was able to dial in the mixture screw to get the little hole under the main outlet to stop leaking.

I found old Evinrude literature that explained how to set the mixture screw. The OFF on the dial really means OFF when seated on this Carb!

I am more used to setting a mixture screw 1-1/2 turns out or so for initial startup.However, I believe Gary is quite correct about the float not sealing at the point of contact between the bowl-hole and the needle valve taper.

Some History:

Through it’s 65 years, This old girl was messed with quite a bit. Either by owners or bad marine mechanics.

The motor is pretty complete. I even have the side cover tins!

I am a precision machinist by trade. Getting the Carb and fuel system apart was a challenge. There were many slotted fasteners that were mangled from slippage with the universally loved slotted screwdriver! Us machinists live in a word of Allen-Head/Hex Key fasteners. There is not much other style used in a machine shop. Hex is a distant second even! Anyways, I was able to restore the old slotted fasteners by hand lapping down the (Doh’s!) and even re-cutting the slots.Which leads me to the Float Bowl:

When I had the Carb. all apart. I noticed a burr around the hole where the needle valve seats. Being a machinist, I took a 90 Deg. M.A. Ford Uniflute Contersink by hand and gave the hole a light twist to remove the burr.

Now, I doubt that the .005 de-burring job I performed would cause the needle valve not to seat….but.

If I leave (2-5 min) the fuel petcock on. And if I leave the mixture screw set to five. The engine will flood and be hard to start.

The leak I had before under the output hole is fixed. (I adjusted float all the way down with just maybe .030-.040 worth of needle open/close play)

But now, 2-5 minutes later, at the above settings, the fuel will leak into the engine and flood.So to remedy this, at every fishing stop, I must remember to shut the petcock off (made a nice knurled brass knob for that) shut the mixture screw to OFF. And turn the throttle to STOP.

Then when ready to go again. Reverse the procedure.

It works, but I still feel I am missing a small detail? Maybe the lap-job is in order on the needle valve?

I will get into it again this winter. I will try to take pictures and post my work. The entire outboard needs paint. So once I am happy with the performance, I intend to strip her down, Zinc Cromate prime and paint her up!

Any suggestions on factory colors and where to get them??

Thanks again for all your help and interest.

John – SportwinDude

October 27, 2016 at 9:52 pm #46593 -

AuthorPosts

- You must be logged in to reply to this topic.