Home › Forum › Ask A Member › 1956 Evinrude 15 HP Model 15016 con rod

- This topic has 10 replies, 5 voices, and was last updated 4 years, 8 months ago by

olcah.

olcah.

-

AuthorPosts

-

June 20, 2021 at 10:34 am #240725

Did the push test for bearing wear with a wood rod on the cylinders. The top cylinder has a small amount of motion. Estimate .003 in. The piston rods on this motor have needle bearings on the crankshaft end and a plain bearing at the piston pin. Is this ok? I plan to use this motor, maybe a lot. If I need to fix, what is the best way? Replace piston/rod combination?

June 20, 2021 at 2:41 pm #240745.003″ of slop surely doesn’t seem like much to worry about….Keep in mind that what might seem like slop in the rod much just be a bit of sideways slop in the piston… I would just try to run it, excessive rod slop will be audible at idle speed if it is an issue..

June 20, 2021 at 4:15 pm #240765Fleetwin, Thank you!

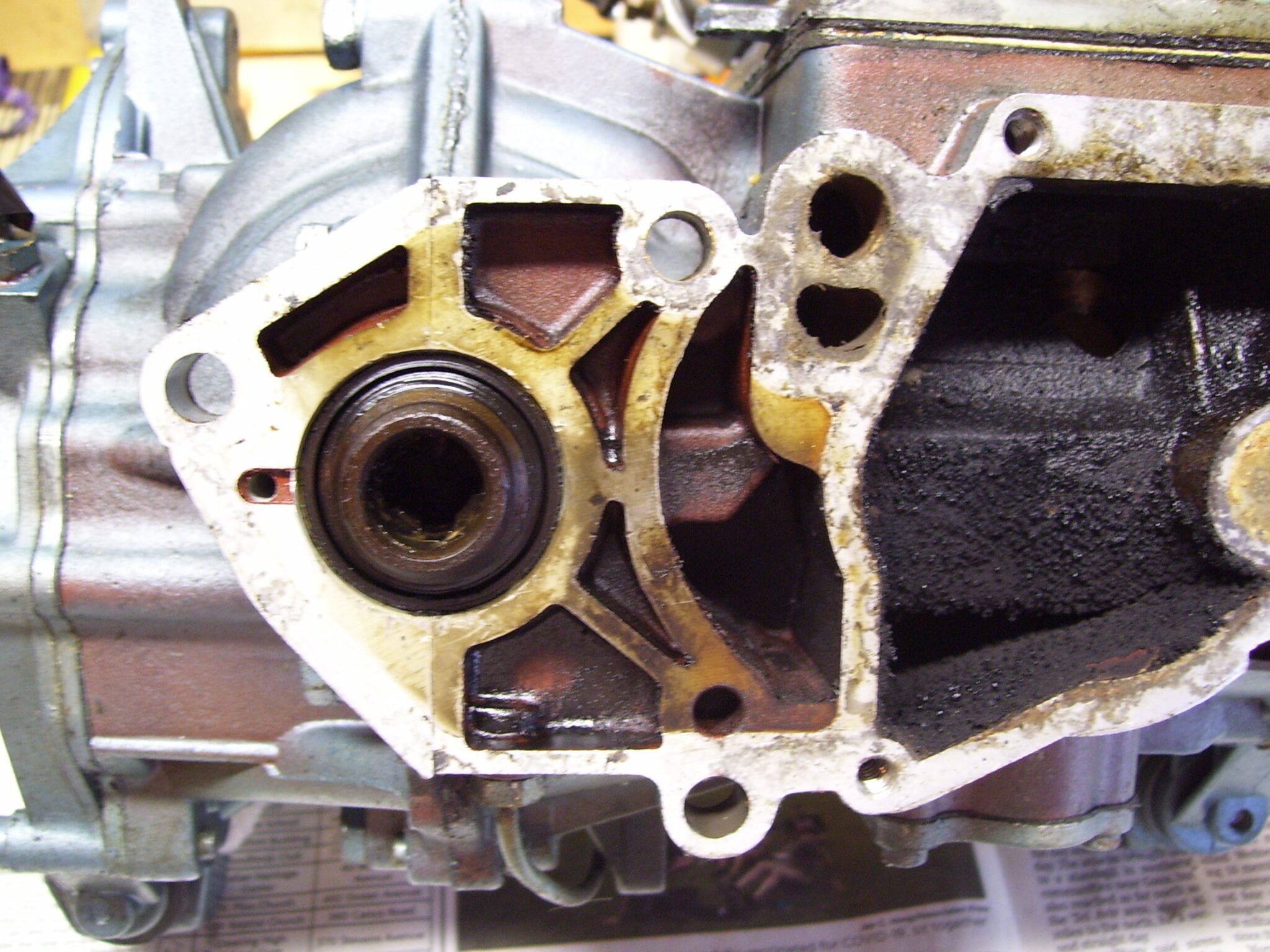

June 20, 2021 at 4:20 pm #240766The motor has the notorious 303804 bottom crankshaft seal (see photo). How do I get the seal out to replace it without opening the crankcase? I have seen explanations in past threads but they seemed hard to follow. I am very concerned that the crankshaft seal surfaces could get damaged.

-

This reply was modified 4 years, 8 months ago by

Mumbles.

Mumbles.

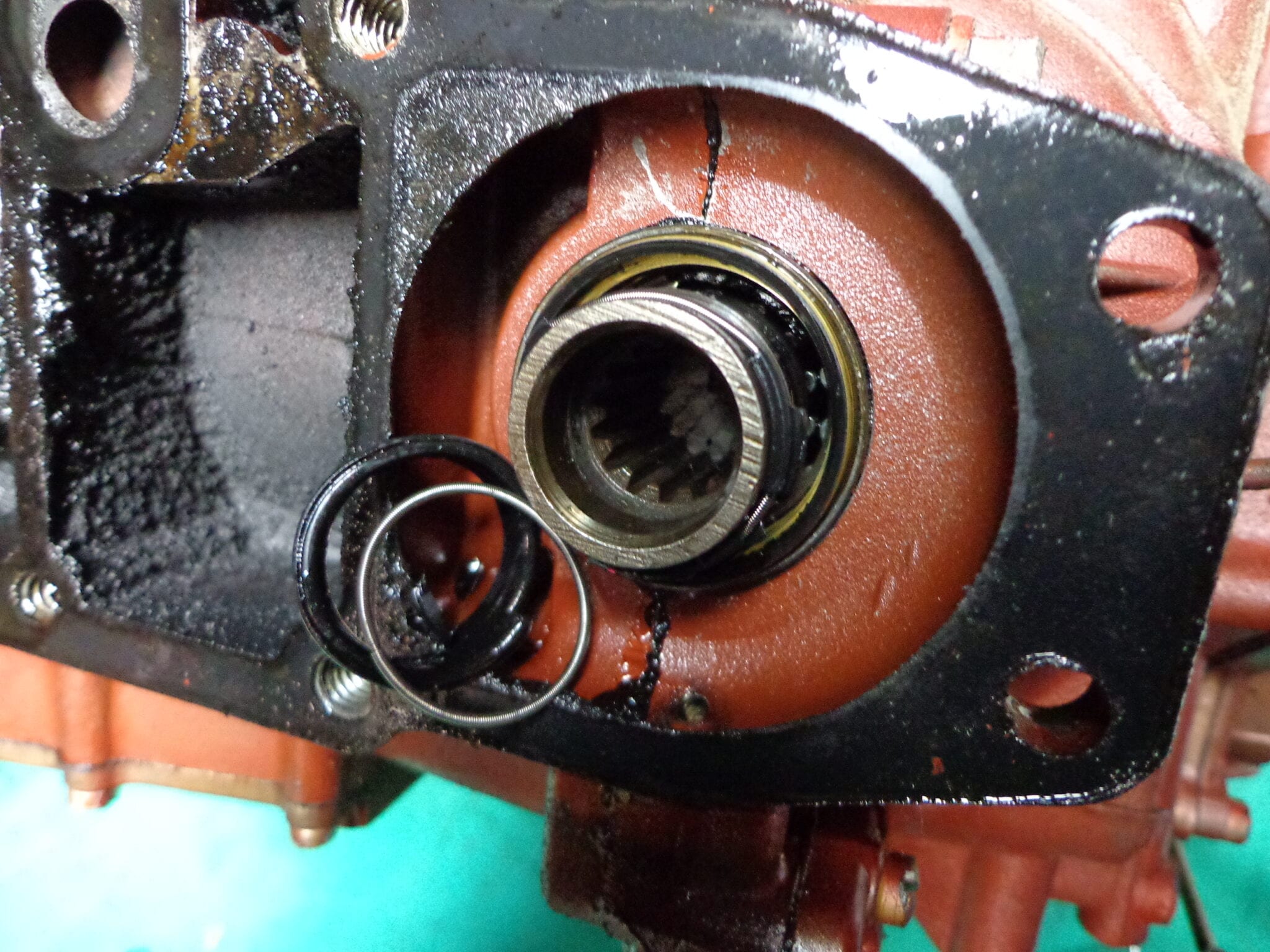

June 20, 2021 at 6:23 pm #240777There might be a way to R+R that seal but if they haven’t fallen out already, I like to split the cases so I can have a good look inside anyway. It’s also a good time to change the upper seal to while the crank is loose. The rubber is what falls out, leaving the metal outer case behind.

June 20, 2021 at 7:15 pm #240781Mumbles,

Thank you. I will probably open the crankcase too. I was hoping to avoid that step but it looks like no one has a magic bullet.

🙂June 20, 2021 at 8:20 pm #240782Actually, it isn’t hard to pry out with a screwdriver.

June 20, 2021 at 9:36 pm #240783Frank,

Thank you. I will look the seal over carefully. Do you have any tips that would help prevent damage to the crankshaft seal area?June 21, 2021 at 9:01 am #240812If you have a old screw driver you could grind a radius on it to match the seal bore,

and sand any sharp edges off the screw driver. I have an assortment of little

wood blocks handy for using under my pry bars for leverage.

Last year I replaced the crank seals on three Big Twins…. opened up the cases

on all three which made seal replacement “easy”.Prepare to be boarded!

June 21, 2021 at 10:07 am #240821Thank you Buccaneer.

-

This reply was modified 4 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.