Home › Forum › Ask A Member › 1956 OMC 15HP Crank Seal

- This topic has 14 replies, 5 voices, and was last updated 2 years, 9 months ago by

olcah.

olcah.

-

AuthorPosts

-

April 6, 2022 at 4:46 pm #257564

Recently I have been working on two 1956 15 HP. One Evinrude, One Johnson. Also I have another 1956 Evinrude 15 HP for parts. All three of these are the same basic motor and have the same crankshaft part number.

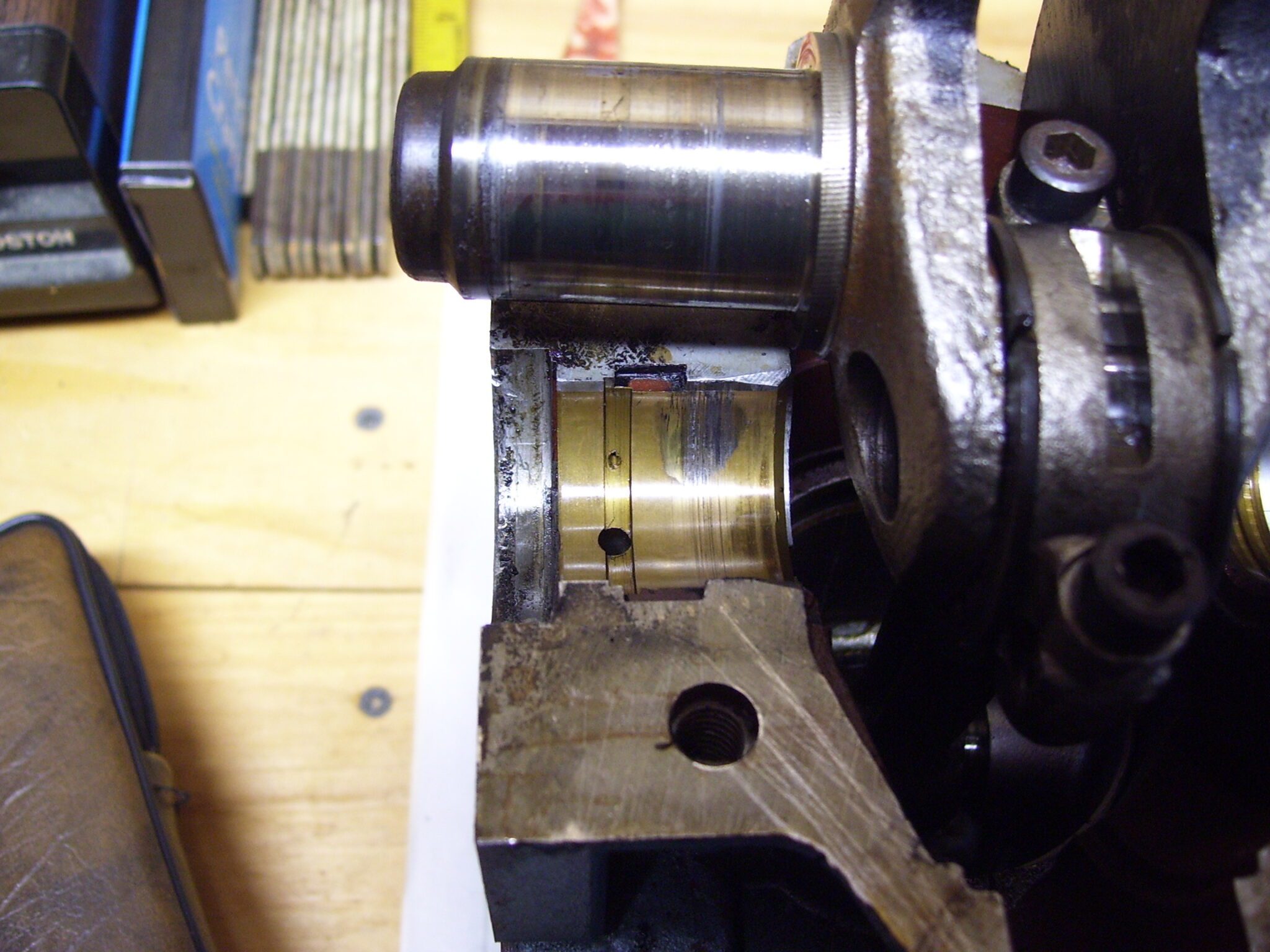

Last summer I assembled the powerhead on the first Evinrude. See photo of the crankshaft around the lower seal. Notice that lower crankshaft journal extends thru the seal area and slightly beyond the crankcase as is usual. Also there is a bevel on the crankshaft to make installing the seal easy.

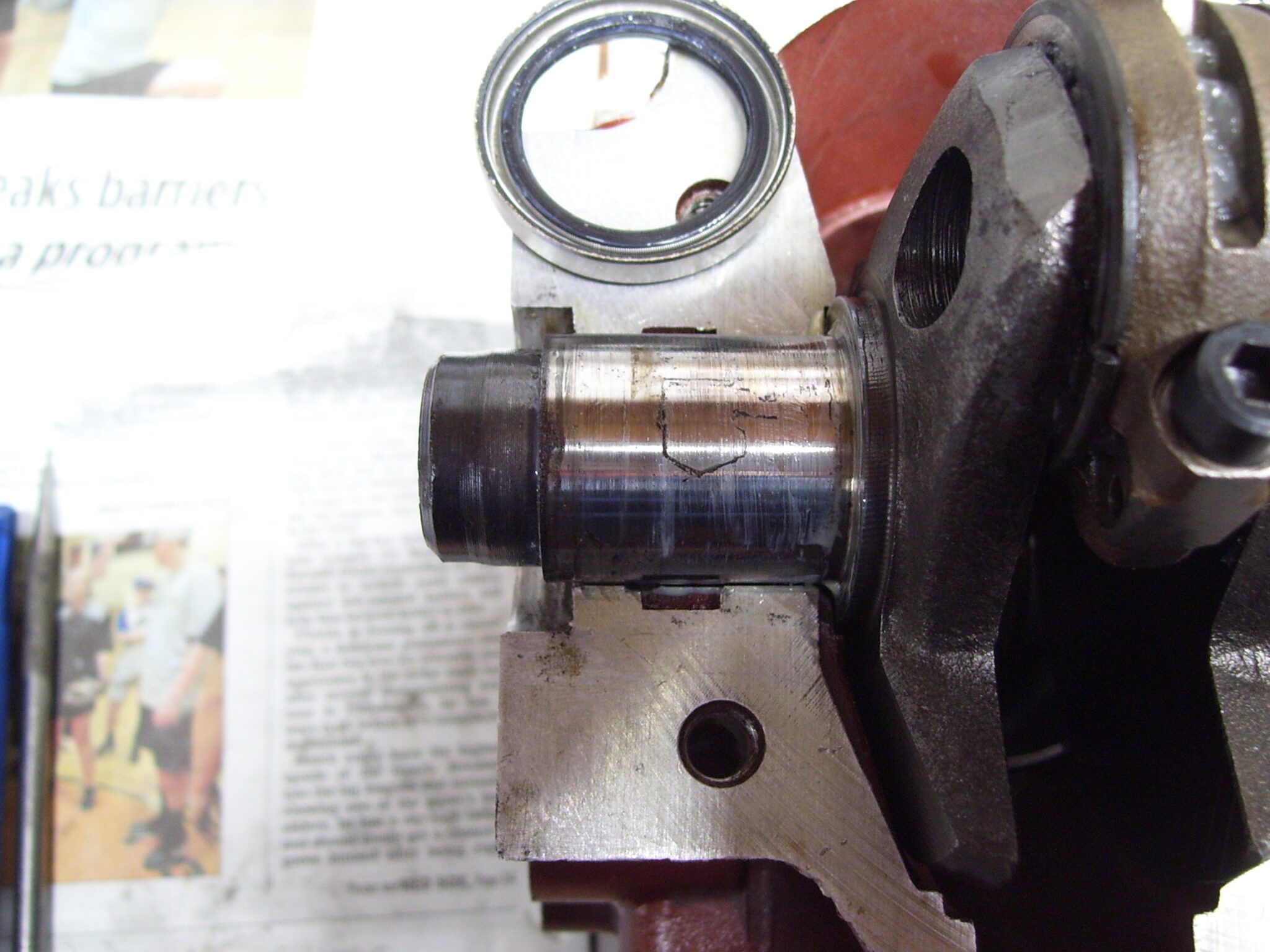

Next photo shows that area on the Johnson that I am assembling now. The lower crankshaft seal surface does not extend thru the seal area . Also there is no bevel on the crankshaft. The standard seal does not touch on the seal surface. I does not ride on the seal surface of the crankshaft.

Looked at photo of the parts motor and the crankshaft end appears to have the same problem. Seems to me like the lower crankshaft was machined in error and the bevel was removed and the seal surface was shortened. Hope I am missing something. ??

April 6, 2022 at 5:17 pm #257569What you are missing is the big screw-up that OMC made. Those cut-down cranks had stainless steel rings on them, similar to speedy sleeves, for the seal to ride upon, Great idea, I suppose, however the stainless rings promptly fell off, rendering the seal useless. Of course, then water entered the crankcase and destroyed everything inside. Many didn’t even make it through the warranty period, especially here in salt water country. OMC had to replace many powerheads because of this engineering snafu.

1 user thanked author for this post.

April 6, 2022 at 5:55 pm #257570Frank,

Thank you so much for this history. I would never have expected that. Guess I should look for another crankshaft. (Too bad it’s off warranty.)

Thanks again.

April 6, 2022 at 9:29 pm #257586Would it be possible to have a sleeve made that you could epoxy to the bottom of the crank that could seal the crank. Just a thought.

April 6, 2022 at 9:52 pm #257587I was wondering that too. Kind of afraid of epoxy because of the heat. It would be easy to make a sleeve and heat shrink it on but the sleeve would only be about 1/16 inch thick so it could just stretch and fall off with time.

April 6, 2022 at 10:06 pm #257589Loctite has/had locking material we use to use on bushings and loose bearings…think it was green…bought from OMC years ago I believe. It needed to be heated up real good to remove what you were “glueing” in.

April 7, 2022 at 1:07 am #257595What you are missing is the big screw-up that OMC made. Those cut-down cranks had stainless steel rings on them, similar to speedy sleeves, for the seal to ride upon, Great idea, I suppose, however the stainless rings promptly fell off, rendering the seal useless. Of course, then water entered the crankcase and destroyed everything inside. Many didn’t even make it through the warranty period, especially here in salt water country. OMC had to replace many powerheads because of this engineering snafu.

Hello. I have a 1956 Evinrude and a 1956 Johnson 15HP. How common was it to have a crankshaft that was engineered wrong? What are the options to correct it or is there no options. Also if you remove power head can you see this error or do you have to disassemble the crankcase? Thank You.

April 7, 2022 at 3:11 am #257597OK, here are a couple of my thoughts. First off, I can’t remember whether those things split and fell off, or stretched or heat-expanded, or what. I suppose 60 or 70 years is excuse enough to forget. But I do remember removing gearcases for water pump service and finding the ring dropped down on top of the pump housing. And/or discovering it too late, after powerhead destruction happened.

I agree, Locktite seems to be a logical solution now. But was it even invented yet in 1956? I do think they were pressed on or shrinked on back in The Day. I certainly think I’d try the Locktite solution if I had one to fix now.

How common? Well common enough that I replaced two or three powerheads under warranty—and we weren’t even Evinrude dealers yet.

Pretty sure you could see it if the powerhead is off.

April 7, 2022 at 7:35 am #257600If powerhead was off one could tell if the crankshaft was cut down by looking for the bevel up to the 1″ diameter seal surface near the end of the crankshaft. See the first photo. No bevel means cut crankshaft. (2nd photo)

February 16, 2023 at 3:08 pm #272787Brought this old thread back with an idea to save the crankshaft. What if I made a sleeve of plain carbon steel not hardened. Then slipped it onto the shaft and welded just the outer end of the sleeve to the crankshaft? Maybe just weld three spots 120 degrees apart. The seal would be running against plain steel. Wouldn’t the seal wear on that surface for a very long time? Maybe the welding would soften the hardness of the crankshaft internal splines. But wouldn’t the splines still wear for a long time?

Any comments/thoughts please.

-

AuthorPosts

- You must be logged in to reply to this topic.