Home › Forum › Ask A Member › 1957 Evinrude 25930 Crankshaft seals

- This topic has 16 replies, 7 voices, and was last updated 5 years, 9 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

May 5, 2020 at 12:07 pm #202069

I popped off the crankcase front cover to inspect, and replace

crankshaft seal and o-rings.

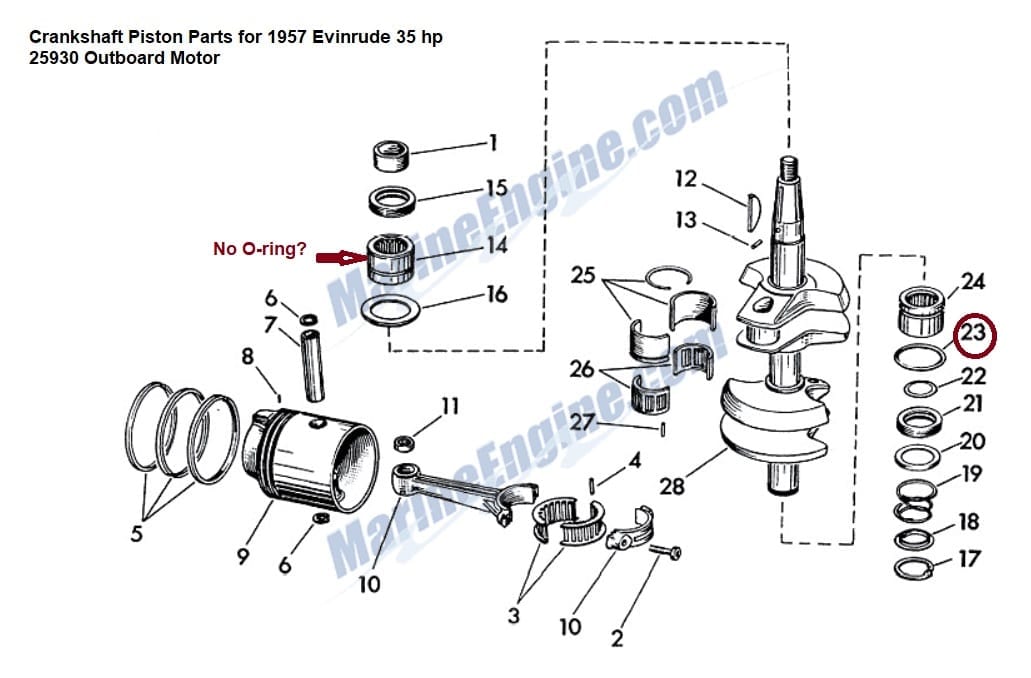

The lower crankshaft had the o-ring (302537, part #23) as shown in the diagrams on ME,

(sits around the needle bearing assembly, and in the crankcase grooves).

The diagram shows no such o-ring on the top, but there was one

when I tore it apart.

Is it suppose to be there?

ME does not have diagrams for 1956 available, so I could not see

if someone used an older and different designed, part.

The old o-rings appears the same size on top and bottom of the crank, but I will have to recheck that.Also, is the crankcase halves o-ring seal the same diameter stock

as used in the lower units? ME offers the stock in a 50′ roll (309044)

but doesn’t give the specs. They don’t suggest buying a roll of o-ring stock

for the lower unit, but just list the individual part.Thanks!

Prepare to be boarded!

May 5, 2020 at 12:30 pm #202074Everybody, it seems, asks the same question. NO, there is not supposed to be an o-ring around the top bearing. That groove is a collector groove leading down to the intake manifold.

The spaghetti seal is the same stuff used in the lower units. Buy it cheap at mcmaster.com They call it 3/32″ buna-N cord stock, 70 durometer.

May 5, 2020 at 2:07 pm #202078A great question indeed. It would surely appear that the omission of the oring in the diagram must have been a mistake. But, like Frank says, this engine is one that uses that crazy vacuum drain system that is supposed to draw any fuel/oil down from that area into the intake manifold. I have always questioned this design. With no oring, fuel/oil will most certainly sneak by that bearing when subject to pressure in the top crankcase. It is a real shame that the engineers didn’t incorporate both systems, use the standard oring design to seal off the crankcase, but add the vacuum drain idea to catch anything that might sneak by the oring or upper seal. Many guys (including myself years ago) just added the oring to the existing groove in the bearing, which is a big mistake. The oring blocks the vacuum port in the crankcase and often times creates an oily mess.

You mentioned that your engine had an oring around the upper bearing when you pulled the crankcase apart. Did it appear that the crankcase had been apart before? I looked in the 1957 book, sure looks like it does show an oring being used. I sure don’t want to create more confusion, so please confirm your model number and recheck the parts breakdown…It would be a real shame to get this thing reassembled only to have a oil leak under the flywheel….

OK, just reread your post….It would appear as though you have a 1956 model engine, but are using the 1957 literature? Do I have it right now? I would definitely find the correct parts list for your engine before reassembly. Again, you mentioned that the upper bearing had an oring when you pulled it apart…It would be a shame to reassemble this engine only to have an oil leak under the flywheel due to the omission of the oring.-

This reply was modified 5 years, 9 months ago by

Don. Reason: addition

May 5, 2020 at 3:19 pm #2020801956 is a 30 HP. No 35 HP in ’56 I don’t know if it makes that much of a difference

www.kenadianoutboards.com

May 5, 2020 at 3:47 pm #202082yes, 56 was a 30hp. May or may not be different…Hard to know without the proper parts book. And, this issue is clouded further because there was an oring in place when he pulled it apart….

Yes, someone may have had the engine apart and accidentally installed the oring on the upper bearing. The 1957 book shows the oring being used… At this point, we don’t know what year engine he is working on… I just don’t want him to reassemble the powerhead without the oring if indeed one is called for. And, just as importantly, I don’t want him to add the oring if it is not supposed to be used on his engine…. Either case will result in an oil mag plate and having to pull the crankcase apart again….May 5, 2020 at 4:07 pm #202086Thanks for the replies. To the best of my knowledge, I’m working on a 1957 engine.

The model number on the transom mount and core plug is 25930. I was just “wondering”

if someone could have used a different needle bearing assembly from, say, a 1956 (or other)

model that did use an O-ring on the “upper”. ME doesn’t have diagrams prior to 1957, so

I could not check up on that theory. ME’s diagrams seem to have many errors.Fleetwin, you say the 57 book shows the oring on the upper and lower needle bearing?, if

so, I’ll certainly put on back in.I checked all the tiny bearing oil drainage passages “as open”.

I had some McMaster buna stock for the lower unit, so I’m good to go. Thanks!Prepare to be boarded!

May 5, 2020 at 4:33 pm #20209025930 is a 1957. I don’t have the ’57 parts book, but I do have the 1956—NO o-ring. Even moving way ahead to 1959—still NO o-ring. Look in that groove. Do you see a small hole that leads to the intake manifold if you blow through it? Would you expect them to go to the expense to drill those passages, then block them with an o-ring? Anybody got a service bulletin addressing such a change? I’ll listen.

May 5, 2020 at 4:51 pm #202091No O ring on either the ’56 or ’57. They have a pressed in lip seal on the top bearing and the same bearing assembly was used for years.

May 5, 2020 at 5:21 pm #202095Thanks again for your keen detective work. I went back out to the shop, took some photos, and

thought about it for a while. Guessing that this 57 BigTwin has been apart before by the looks

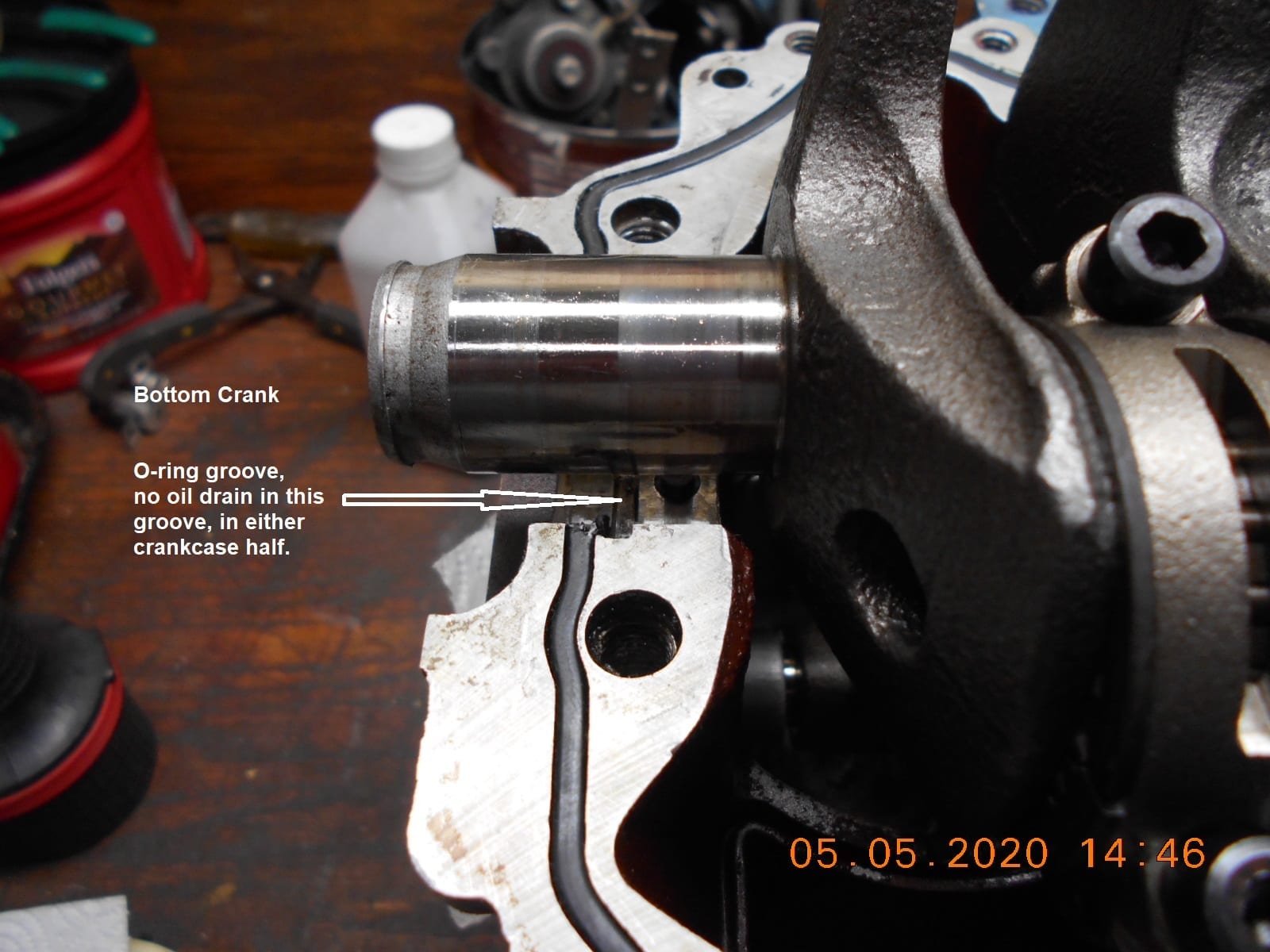

of the slop job on the sealant, and someone decided to put an o-ring in that top groove.As you suggest, the bottom crankcase has no oil drain passage in the crankcase groove,

and an o-ring makes perfect sense there. The front crankcase cover does have a drain hole,

but above the o-ring groove a ways.The top crankcase groove does have an oil drain passage in front case half, and as Frank says,

it would make no sense to block it……. besides, gravity should help out some here, as well as

the neopreme rubber seal at the very top.An o-ring can’t go in the needle bearing assembly groove, as the locating pin in the crankcase half

would be against that idea.I’ve never seen this motor run, and have no idea how long the errant o-ring was in the top of the

crankcase, but don’t see where it caused any damage. None the less, I will omit it upon

re-assembly.

Thanks! and Happy Cinco Di Mayo!Prepare to be boarded!

May 5, 2020 at 7:11 pm #202113Per your picture, see the milled slot right under where your arrow is located? Consider this: Any oil that manages to seep through a less-than-perfect upper crankshaft seal would run down that slot and be drawn off to the intake manifold, along with any oil that manages to escape around the outer shell of the bearing. The same scheme was used on bushed engines that had a slinger only and no seal. Hey, good or bad, agree or disagree, it was the OMC way at the time.

BTW, my estimate is that most of the black crudded up armature plates back in those days were from vibtation-liquified over-greasing of the armature plate support rings. Of course this is now and the seals have had a lot more time to start excessivly leaking.

-

This reply was modified 5 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.