Home › Forum › Ask A Member › 1957 Evinrude 25930 Crankshaft seals

- This topic has 16 replies, 7 voices, and was last updated 5 years, 9 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

May 5, 2020 at 7:34 pm #202118

Buc, If you follow those drilling you will find that they start on the pressure side of the read plate, (crankshaft side). Then go to the lower main bearing. Excess oil/gas mixture is sent up the tube to the top main bearing. That excess ends up on the suction side of the reeds (carburetor side). Quite an interesting engineering concept! Gobbed up sealer will kill the operation of this little pump! Most of the fifties OMC and other motors have something along this line for extra lube for the main bearings.

dale

May 5, 2020 at 8:27 pm #202127Dang-it.

Y’all are making me second guess my work on quite a few motors!

Should I tear one apart to check if it’s done wrong?

Is an oily mess the only concern if that oil passage is blocked?

GJMGP

May 5, 2020 at 8:37 pm #202132OK, sorry for my confusion…Was looking at #23, but got confused, those parts are the lower bearing pieces, not the upper bearing….The vacuum port is in the groove where you found the oring….

So, looks like you don’t use the oring on this engine. I thought you had a 1956 engine, but could only find this 57 parts book…Oh well, sorry…

It’s too bad engineering couldn’t have put the vacuum hole just above the groove that would normally hold the oring, then you could have both systems….I guess this might not have worked out because the crankcase mag plate pilot bushing would be just behind the hole if it was raised up. My issue with this system has always been that removing the oring allows gas/oil to sneak by between the upper bearing case and block. This engineering “improvement” added a bit of a leak, I guess they felt the vacuum port would make up for it….

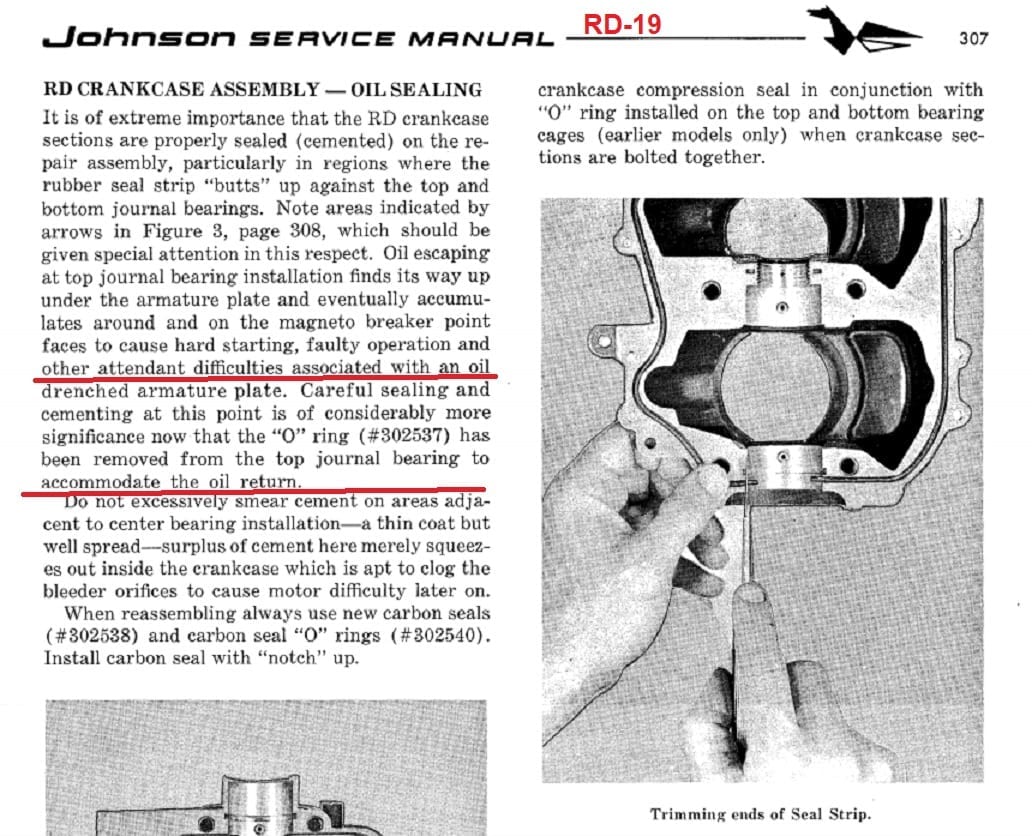

I see traces of the red gel seal on the block which would indicate this powerhead has been apart before, which would explain how the oring got in there. DMay 5, 2020 at 9:39 pm #202140In looking at the shop manual, it looks like some of the earlier RD’s used a carbon seal

and O-ring on the top and bottom of the crank. Is that correct?Prepare to be boarded!

May 5, 2020 at 10:13 pm #202144May 5, 2020 at 10:15 pm #202147In looking at the shop manual, it looks like some of the earlier RD’s used a carbon seal

and O-ring on the top and bottom of the crank. Is that correct?That is correct. I think it was 1955 that they replaced the top carbon seal with a lip seal. Subject to correction. But that’s ok.

May 6, 2020 at 8:33 am #202166Buc, If you follow those drilling you will find that they start on the pressure side of the read plate, (crankshaft side). Then go to the lower main bearing. Excess oil/gas mixture is sent up the tube to the top main bearing. That excess ends up on the suction side of the reeds (carburetor side). Quite an interesting engineering concept! Gobbed up sealer will kill the operation of this little pump! Most of the fifties OMC and other motors have something along this line for extra lube for the main bearings.

dale

Dale, I confirmed all the little oil passages were open using WD40 and compressed

air. I also took the little reed pump apart and cleaned up that cavity well.

Tried to find out what the 10th edition manual might say about the little

reed pump, but could not find it.

What’s the official name of it?Thanks!

Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.