Home › Forum › Ask A Member › 1958 Johnson 10 hp Model QD 19 Cam issues

- This topic has 6 replies, 7 voices, and was last updated 5 years, 9 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

May 5, 2020 at 5:56 pm #202107

Y’all have been most helpful.

I have ordered carb kit

Ignition kit

And Impeller kitWhen checking the existing points, I noticed when I turned the cam shaft – points did not open and close. My first guess was maybe the point contact lobe was overly worn down, which may be. Obviously when the new points come I can do a comparison. The points contacts though looked like there was no wear. Inspecting the cam, I see no rise – figure there would be two high points. But looks like just a large bushing with having a micrometer?

What am I missing in my review of situation??

Thanks for helping a novice.

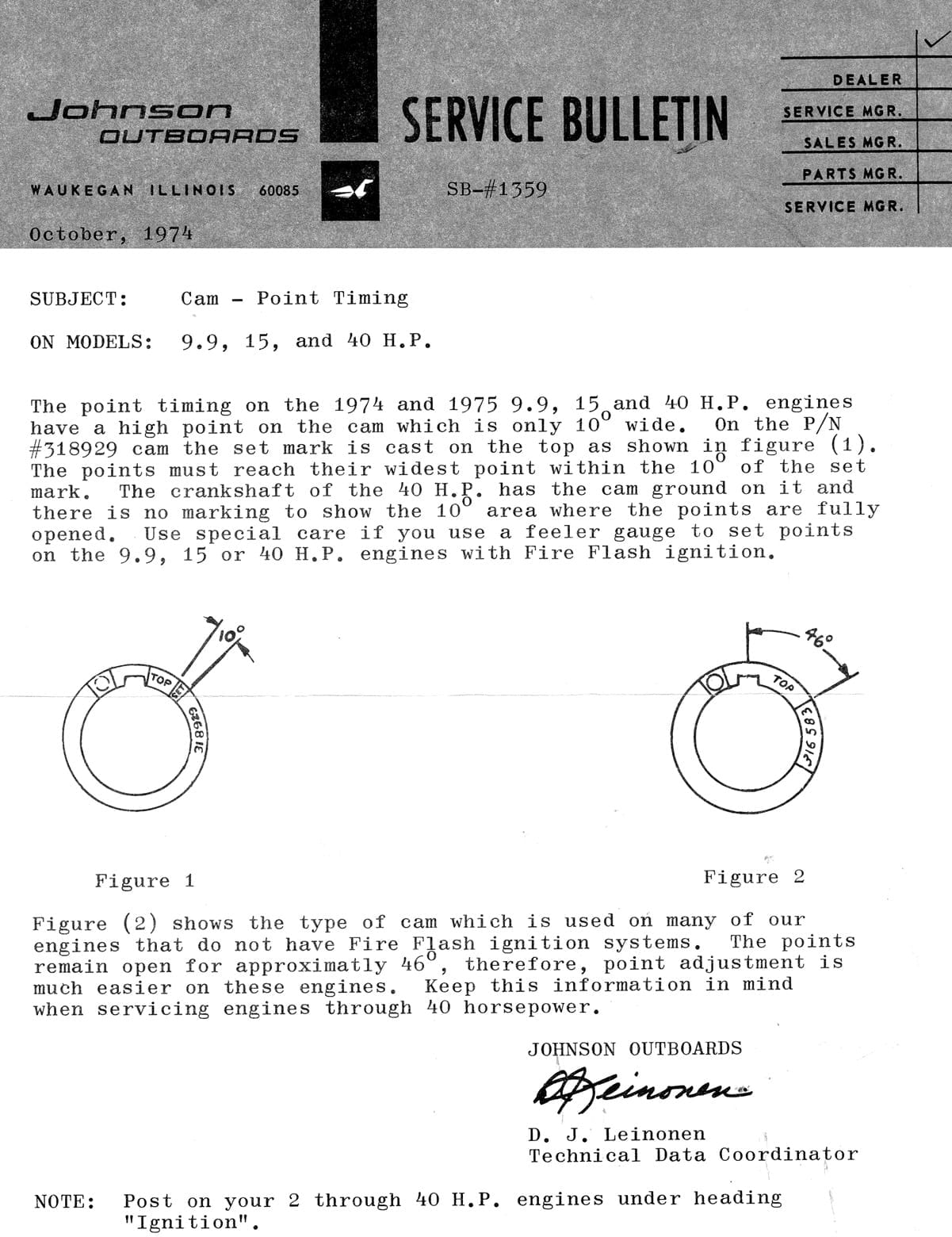

May 5, 2020 at 6:04 pm #202108To help narrow it down, the high point on the cam should be somewhere near the word “TOP” on the cam. Here’s a file that illustrates the range at which the points are open – the cam on your motor will be as shown in Figure 2.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."May 5, 2020 at 6:46 pm #202111That was the old way, anyone have the page referring to the use of the timing tool?

http://www.richardsoutboardtools.com

classicomctools@gmail.comMay 6, 2020 at 9:28 am #202171That was the old way, anyone have the page referring to the use of the timing tool?

That is not going to help the poster with his original question, possibly will confuse the issue.

Possibly cam is on upside down as well.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

-

This reply was modified 5 years, 9 months ago by

David Bartlett.

David Bartlett.

May 6, 2020 at 10:02 am #202180something strange here… you were “checking” the points”….

was the motor operational before you decided to check the points ? is this a new motor for you ?

the issue has crept up on other posts …” points do no open or can not be adjusted ! ” are these a new set of points or the original ones ?

Joining AOMCI has priviledges 🙂

May 6, 2020 at 11:10 am #202185Retired Gunny here. I read this post because it is so close to what I’ve been watching the last few days. Here are my observations. When I use the timing tool, I notice that the points would start to break prior to TDC. My conclusion here would be that this should be the beginning of the break allowing the spark during the 46 degrees shown above. I’ve noticed that at TDC, the points are opened. however, the timing marks do not line up correctly.

I don’t think that your cam is worn, you would have to have a really noticeable groove in there that would take years of continual motion to accomplish, I thought that myself, no evidence on the cam of any wear.

I have matched the timing tool to the flywheel marks, after all, all you are doing by using the timing tool is replacing the flywheel for easier accessibility and visibility. Myself, I’ll use the timing tool and the multi-meter watching for continuity versus watching the gap.

These are just my observations from the last few days, glad I’m retired and have nothing better to do with my time.

May 6, 2020 at 12:18 pm #202199When you turned the crankshaft to observe the points opening, had the spring for the top seal pushed the cam up and away from the points rubbing blocks?

Normally, the flywheel holds the cam down in place but it will spring up once the flywheel is removed, unless it’s seized onto the crank. Replacing the flywheel on a QD or Sportwin can be tricky to as the crankshaft must be positioned with the rubbing blocks at the lowest points on the cam and the keyway lined up at the same time.

-

This reply was modified 5 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.