Home › Forum › Ask A Member › 1960 Scott 7.5 hp Carb “Purge Valve”

- This topic has 6 replies, 3 voices, and was last updated 2 years, 10 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

March 15, 2023 at 6:11 pm #273935

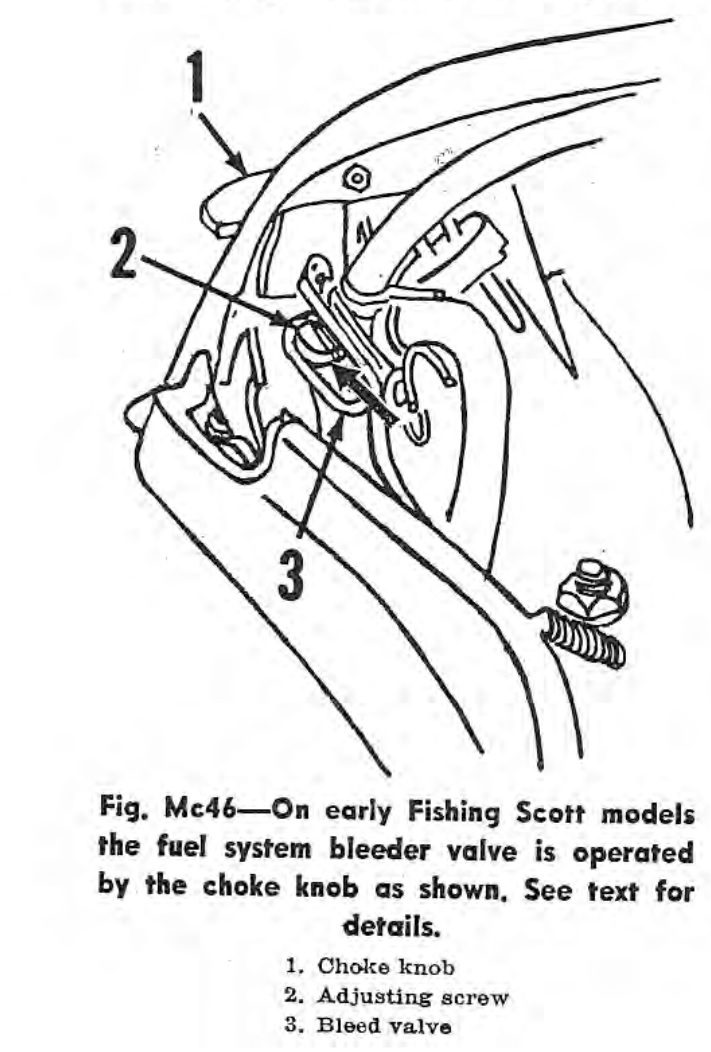

The carb rebuild instructions in the manual says –

“Prior to starting the 7.5 hp motor it is necessary

to purge or bleed the fuel system of excess air.”It goes on to say that there’s an “early” and “later”

bleed system. The early one has a bleed valve activated

by holding the choke knob “in” while squeezing the primer

valve, and the later model activates by twisting the throttle

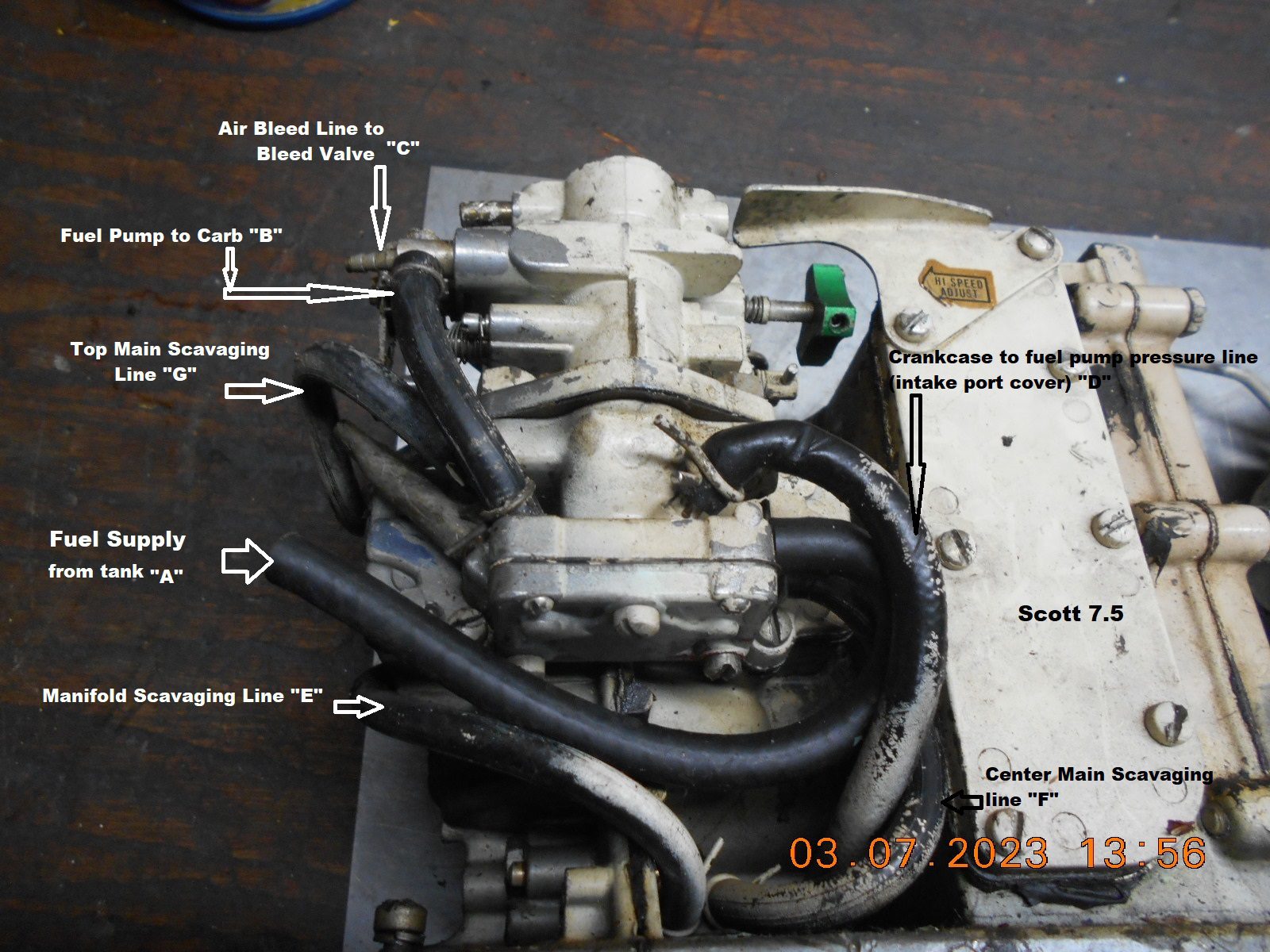

control to the “vent” position while squeezing the primer bulb.My motor does not seem to have either system, but the fuel inlet

nipple on the carb has an extra barb for the bleed system, but

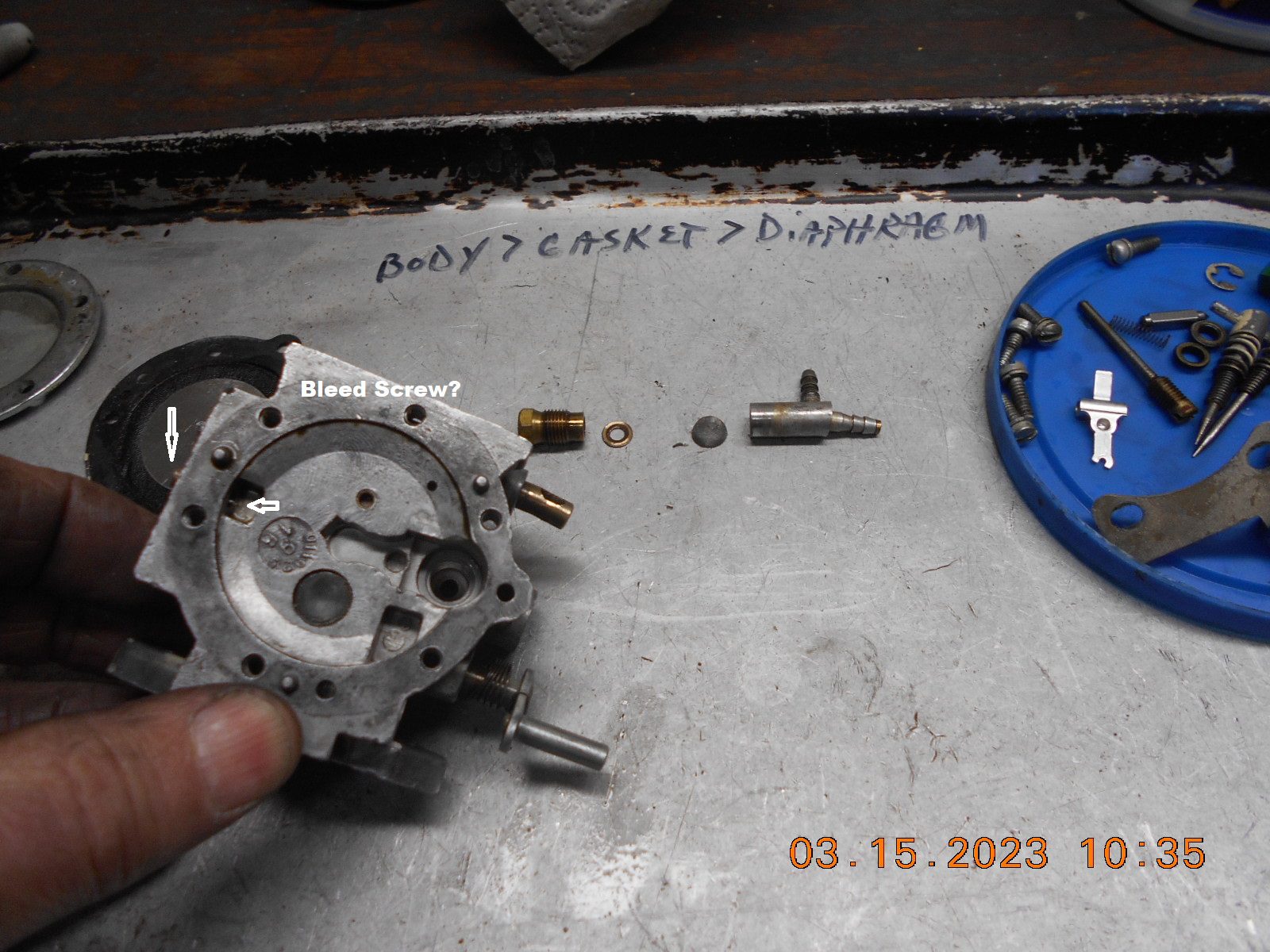

it’s not drilled out.When I had the carb apart, I did note one little brass plug between

the high and low speed needles, that plugs a galley into the

fuel side of the carb diaphragm. If one removed the plug and

squeezed the primer bulb, I would think it would purge the air

out of the fuel pump…… “BUT” it would dump gas into the

motor housing, and would be a P.I.T.A. to get at the plug,

and not to drop the little bugger.Anyone have any experience with these?

Hopefully it’s just a “once in a great while necessity” to

purge out the air.Prepare to be boarded!

March 15, 2023 at 8:39 pm #273943Ah yes, the Tillotson model H diaphragm carburetor designed for chainsaws. I barely remember the purge valve. Actually not at all till you mentioned it. The deal is, the arm that opens the inlet needle valve is held closed by that little spring. When the engine is running, gas is sucked from the diaphragm chamber, causing a vacuum which moves the diaphragm towards the lever, over-coming the spring, and more gas can enter the diaphragm chamber. Not much different than a float valve carb, if you think about it. In chainsaw use, with the gas tank above or at least close, yanking the pull rope a dozen times eventually creates enough suction to open the diaphragm valve and hopefully it starts and continues to run. Different story when they put the carburetor a foot or more above the gas tank. Hense the purge valve to get the gas at least close to the carb and maybe start with a dozen pulls.

As for the details of the purge system, duh, I forget.

March 15, 2023 at 8:46 pm #273946After writing that, and pondering about it a bit more, isn’t the purge valve at the entry to the carburetor and not part of the carburetor itself?

March 15, 2023 at 9:39 pm #273948Frank, thanks for the reply. The manual didn’t actually show either style

of purge valve that I could see, but one was operated by the choke being

pushed in, and the other by the throttle mechanism when the

twist grip was turned to “vent” position. (past “fast” I think).

This makes me think the actual bleed valve was behind the front

face plate. It sounds like the valve was plumbed so when air purging

was taking place, the air / gas would dump visibly out a hose some where.That barbed fuel inlet nipple at the carb, shown in my photo with all the hoses,

must have been the supply to the bleed valve. The nipple on mine was

never drilled though, so perhaps another design change not mentioned

in the manual, but mine being a 1960 should be on the “early” production

end of these motors.Prepare to be boarded!

March 16, 2023 at 5:49 am #273958I have nothing useful to add, but what is the green knob for? Is that OEM? I’m working on a 9 McCullough which is a similar motor but has a more conventional carb, thank God. I thought MINE was bad.

Long live American manufacturing!

March 16, 2023 at 9:46 am #273961Bill, green knob is the HS needle. I “think” it’s original.

I’ll have to look at the Hiawatha powerhead with the same

carb to confirm.Heading out to figure out all those hoses….. or not!

Prepare to be boarded!

March 16, 2023 at 10:37 pm #274021 -

AuthorPosts

- You must be logged in to reply to this topic.