Home › Forum › Ask A Member › 1964 Evinrude 9.5? Identify and Maintenance

- This topic has 69 replies, 8 voices, and was last updated 2 years, 5 months ago by

joecb.

-

AuthorPosts

-

August 2, 2023 at 6:26 am #278738

Even with the flywheel off on this model, you cant remove the carb. There is a sliding plastic triangular thing that slides around the teeth at the bottom of the flywheel that is in the way even when the FW is off.

August 2, 2023 at 12:24 pm #278749So sorry buddy, this project seems to be going south on you….

You are going to have to deal with the overheat situation now, before getting back to the original issues. I suppose it is possible that you just picked up a plastic bag which plugged this water intakes, but you really need to remove that gearcase now and have a look at the water pump. I am guessing this is a fresh water engine, so am hoping the driveshaft splines are not rusted into the crankshaft, which is somewhat common on these low profile engines. Nonetheless, you are going to have to look at the water pump before tending to the other issues.

Try loosening up the four bolts that retain the gearcase, if they come loose without much effort that is a good sign. Don’t force the screws if stuck, you don’t want to break them off. Once the four bolts are out, try prying the gearcase down just a bit. It will only come down about an inch or so due to the shift rod connector. The brass connector will be visible, remove one of the SS connector screws then the gearcase should come off.

Once the gearcase is off, there are four small SS screws that hold the aluminum impeller housing in place. Again, don’t force the screws, you don’t want to break them off. If all the screws come out without much of a fight, you can then lift off the impeller housing exposing the rubber impeller. Is the impeller in one piece? If so, perhaps the rubber part became dislodged from its brass/metal/plastic hub. You could be in BIG trouble if the impeller is broken in pieces.. If so, it is extremely important to find all the pieces (kind of reconstruct the impeller like they do after airline disasters). This is so important, because you want to confirm that no pieces of that impeller have been pushed up the water tube just waited to cause future issues that are near impossible to deal with.

So, let us know how you make out getting that gearcase off and inspecting the impeller. In the mean time, I will look to see if I have a 9.5hp service manual so I can figure out how that carb comes off there. Or, you can just remove the top of the carb to have a quick look inside. But be very careful, don’t drop anything down that carburetor throat..

OK, found a 68 OMC manual for the 9.5hp. It didn’t say anything about removing the flywheel, just said remove the five screws, there are only two on the back side of the carb. The manual did mention something about loosening/moving the “stabilizer bar”, whatever that is. You may need to make sure the throttle/magneto advance is completely retarded though, so that the two rear screws are exposed. Yes, I realize that your 64 model might be different than the 68 model that I read about, but I doubt it.

For now, let’s just have a look at the water pump, and worry about the carburetor later.

1 user thanked author for this post.

August 4, 2023 at 7:47 am #278792Ok:

So I took off the 4 bolts that hold the gearcase on and it came down about a 1/4 inch. I loosended the only screqw I saw that went through a brass rectangle. The gearcase would not come off. Then I loosened it more and the damn screw fell into the cavity. Gearcase would still not come off. I tried not to push or wiggle it too much. It moved laterally, but would not come off.

I started off removing the upper bolts holding the middle section up and the same situation – nothing would come off – there were no release screws there either.

What now?

August 5, 2023 at 8:13 am #278814OK, the four gearcase bolts are out, and one of the SS connector screws is out, even though it fell down into the gearcase. You are sure that the SS screw/bolt is completely removed from the brass connector, correct? The gearcase won’t come down unless at least one screw is completely removed.

Is this a salt water engine, or does it appear to be used in only fresh water?

I’m guessing it is a fresh water engine, or else it probably wouldn’t be in running condition today. What/how have you tried to remove the gearcase? It probably won’t come down just by pulling on it with your hands, which is normal. You may need to help it down using a bit of pressure from a large screwdriver or pry bar. But, please, be as gentle as possible. You do not want to distort/damage/gouge the gearcase/exhaust housing mating surfaces. Gently pry with two large screwdrivers or pry bars, kind of rocking it back and forth. Unfortunately, if the driveshaft is stuck in the powerhead, this may be the end of this project. In other words, the gearcase may come down leaving the driveshaft stuck up inside the powerhead/crank splines. At this point, you have no other option than to try and get this gearcase down.

PS: Exactly what other bolts did you remove? Be very careful, you don’t want to inadvertently split those lower motor covers, or you will be showered with little springs/washers/spacers and mounts!

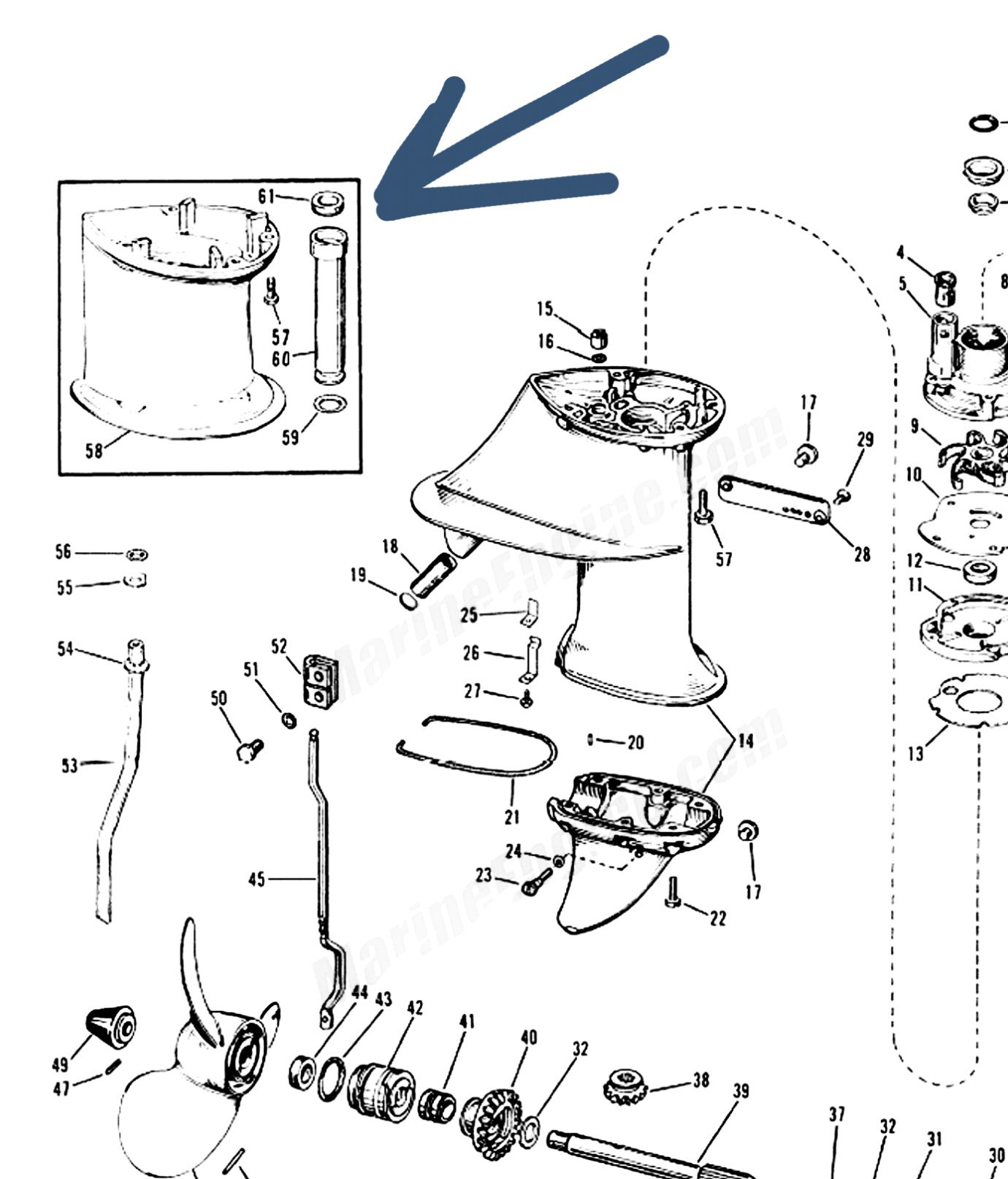

August 6, 2023 at 9:37 am #278867I attached a picture to show the part I am trying to remove. I was taking the 4 bolts off of the bottom of this section.

Yes it is a freshwater engine mostly. My uncle lived in NJ and was a lake guy, but near the end of his life had a place in sarasota and had the boat in brackish water at times. Most of the time in lakes.

I watched a couple of videos (all early 1960’s Evinrude Johnson) and watched at least 3 people remove the thing I am trying to remove – the water pump to access the impeller by opening the gap about the same width as I have and then removeing a screw. Then the whole lower end with the prop came off easily. One guy had to pry open the two brackets that were held by the screw they just removed and then the lower end came free.

But this morning, I tried the same procedure, and the was no give in that space in between the brackets.

August 6, 2023 at 5:25 pm #278885OK, well let’s start with is this a long or a short shaft engine? The arrow is pointing towards the extension piece and the water pump/driveshaft seal tube. I really don’t think this part is hold things together/stuck. You have removed one of the brass shift rod connector screws competely (#50), correct? Have you tried rocking the gearcase back and forth using two large/but dull/blunt screw drivers? Again, please be careful, do not distort/gouge up those mating surfaces while gently prying. I fear that the upper driveshaft splines may be rusted/seized into the crank splines, sure hoping I am wrong. Keep working that gearcase with the two blunt/dull. screwdrivers/pry bars.

If the splines are stuck, eventually the driveshaft will pull out of the gearcase through the impeller housing. In other words, the gearcase will come down but leave the driveshaft behind/stuck into the powerhead. Normally, I would see back away from this situation and just put it back together. But, in your case, the engine has a cooling problem, so that water pump needs to be inspected/addressed. So, there is really no other option than to get this gearcase off. But again, take great care not to gouge up those surfaces while prying. Perhaps you can wedge some wood shim stock up their so you will be prying against that.

August 7, 2023 at 7:20 am #278910I have tried a lot of rocking back and forth. I will try the shim idea. It doesnt feel like the shift rod (45) is the only ting holding this thing in there. I think it is like you say, something higher up towards the motor is stuck.

August 7, 2023 at 7:23 am #278911Also, I cant tilt the motor up anymore. Something goit stuck and now I can’t tilt the outboard upwards like I used to. There is a nut that has the instructions, “push in and turn” – this nut is connected to a cog on the opposite side that is engaged. I assume that if I push it in, the cog will disengage, but it won’t push in. I am getting so frustrated with this thing.

August 8, 2023 at 6:58 am #278944I fixed the tilt thing. Also, I found another odd thing. As I gazed up into the cavity of the water pump area, I saw something rusted and twisted inside. I figured that might be an issue. I took a photo of it. Also there is another photo of the brass brackets that once held the bolt so you can see what I am trying to figure out.

I am still stuck on what to d0? I tried to pry the thing apart with a pry bar. I can’t find my wooden shims. Nothing is moving. I removed the motor from the boat and I got the bolt out that had fallen inside. Is there anyone on this forum in the metro detroit area that can maybe come take a look?August 9, 2023 at 7:39 am #279005OK, well I’m pretty sure this engine is locked down unless shifted into forward gear. And, you probably can’t shift it into forward with the gearcase hanging down like that. So, you may want to just get under the stern bracket with a large screw driver and just pry the tilt lock up and off the trim rod so you can tilt it up.

Once again, is this a short or long shaft engine?? I’m guessing that part you are pointing out is the water tube. Yes, they can get stiff inside the impeller housing grommet, but gentle prying usually pulls them out of the grommet. The shift rod is disconnected, so there is really nothing else holding you up except the darn driveshaft splines. That engine looks like it has seen some salt water use so I fear my suspicions are correct, although I sure hope I am wrong!

The engine isn’t operable the way it is, so there isn’t much to lose by continuing to carefully pry that gearcase down. The only thing holding the driveshaft into the gearcase is the impeller key which isn’t shown in your diagram. Continued prying will eventually force the key through the aluminum impeller housing allowing the gearcase to come down leaving the driveshaft stuck up inside the crank splines. Again, be careful prying, try to avoid distorting/gouging those gearcase/hsg mating surfaces. Don’t worry about messing up the aluminum impeller housing, this part is going to get ruined anyway and can be replaced.

Unfortunately, once the gearcase is down, you are faced with the daunting task of getting that driveshaft out of the crank splines. Trying to use a slide hammer or other puller on the driveshaft usually ruins the seal/bushing surfaces. Usually the powerhead must be removed in order to get the driveshaft out. Removing the powerhead from this engine is a major task, one to be avoided if possible.

Again, I sure hope I am wrong about all this…

-

AuthorPosts

- You must be logged in to reply to this topic.