Home › Forum › Ask A Member › 1965 Ski-Twin Mod 3552B questions

- This topic has 10 replies, 5 voices, and was last updated 8 years, 6 months ago by

amuller.

-

AuthorPosts

-

July 5, 2017 at 12:07 am #7540

I’m looking this over. It seems to be quite simplified compared to the Big Twins I’m been messing with.

No thermostat apparently. I’m used to seeing ‘stats on even little OMC products. Why not here? Is it really a Gale, as some suggest?

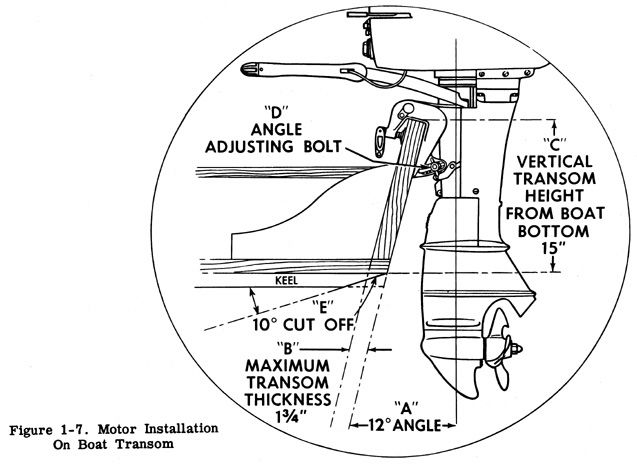

I take this to be a "short shaft" motor. On a 15" transom the pump would be just below the water line, which makes sense But the cavitation plate is several inches lower, leaving a lot of foot dragging in the water. Not sure I understand why it was laid out this way. What am I missing?

It has a nice condition Michigan bronze propeller. But neither of the numbers on it come up: 832B and 217K. Diameter and pitch aren’t marked, which seems unusual to me for Michigan. In any case, I’ve always been reluctant to use bronze props on shift motors as the polar moment is obviously high and seems they would be hard on the gears and dog clutch. Opinions?

Thanks.

July 5, 2017 at 12:39 am #60995How many inches is "several"? The AV plate should be just about even with the bottom of the boat/keel, maybe a bit lower, but not several inches….You could always put a small block under the transom bracket to bring the engine up a bit…

Yeah, no thermostats on these engines…They are based largely on the 35hps of the 50s which had no thermostat.

And yes, I agree about using the bronze props…I wouldn’t use it either, clutch dog wear could be accelerated shifting gears with the heavy prop.July 5, 2017 at 1:04 am #61000Back in those days, boats were made of wood and had keels. Therefor the motors were designed to run deeper. A straightedge extending the boat bottom out should fall somewhere between the water pump bulge and the cavitation (AV) plate.

July 5, 2017 at 2:27 am #61006quote FrankR:Back in those days, boats were made of wood and had keels. Therefor the motors were designed to run deeper. A straightedge extending the boat bottom out should fall somewhere between the water pump bulge and the cavitation (AV) plate.Makes sense.

The top of the AV plate is a full five inches below the centerline of the pump bulge. So, if the motor was shimmed up to align the plate with the bottom of the transom, or the motor was used on a 20 inch transom, seems that the pump would be starting dry sometimes and might not pick up it’s prime. (Though I know there have been successful motors with the pump high in the leg.)

In truth I only got this motor for the internal gearcase parts, but nobody seems to have much bad to say about them.

July 5, 2017 at 7:08 pm #61037The Flat bottom racing type boats I ran had 17" transoms. . . 😆

25 HP – 32 MPH

9.7 HP – 34 MPH

July 5, 2017 at 8:41 pm #61043quote amuller:quote FrankR:Back in those days, boats were made of wood and had keels. Therefor the motors were designed to run deeper. A straightedge extending the boat bottom out should fall somewhere between the water pump bulge and the cavitation (AV) plate.

July 5, 2017 at 8:41 pm #61043quote amuller:quote FrankR:Back in those days, boats were made of wood and had keels. Therefor the motors were designed to run deeper. A straightedge extending the boat bottom out should fall somewhere between the water pump bulge and the cavitation (AV) plate.Makes sense.

The top of the AV plate is a full five inches below the centerline of the pump bulge. So, if the motor was shimmed up to align the plate with the bottom of the transom, or the motor was used on a 20 inch transom, seems that the pump would be starting dry sometimes and might not pick up it’s prime. (Though I know there have been successful motors with the pump high in the leg.)

In truth I only got this motor for the internal gearcase parts, but nobody seems to have much bad to say about them.

Well, I think I understand what you are concerned about, but it might be best to post pictures…

In any event, it is normal for the water pump bulge to be up and out of the water while the boat is planing. The water is actually being forced into the pump by high water pressure against the pick up screen on the exhaust snout behind the prop. So, losing pump prime is not likely….July 5, 2017 at 9:35 pm #61046Someone may have converted it to a long shaft. Dealers commonly did that if they didn’t have a long shaft in stock and had a buyer. Does it have an extra 5 inches of exhaust housing bolted on above the lower unit gearcase? If it is short shaft, it should measure about 18 inches from where the clamps sit on the top of the transom to the cavitation plate. Long shaft will measure 23 inches.

Look again at your model number – it has a typo – should be 5 numbers and may or may not have a letter behind it.

See long shaft below:

July 6, 2017 at 5:20 am #61082Thanks for the handholding on this. Am I correct in thinking that all the long-shaft version of this would have the usual 5" extension? This is definitely a short-shaft (15") motor. A $50 motor. Don’t have the junction box but all it really needs is a solenoid and there seems to be plenty of room for that under the hood. I’m not crazy about the Evinrude styling, prefer the more restrained look of the Johnsons.

July 6, 2017 at 11:22 am #61090quote outbdnut2:Someone may have converted it to a long shaft. Dealers commonly did that if they didn’t have a long shaft in stock and had a buyer. Does it have an extra 5 inches of exhaust housing bolted on above the lower unit gearcase? If it is short shaft, it should measure about 18 inches from where the clamps sit on the top of the transom to the cavitation plate. Long shaft will measure 23 inches.Look again at your model number – it has a typo – should be 5 numbers and may or may not have a letter behind it.

Yr right. It’s 33552B. I dropped a 3. Thanks for the correction.

See long shaft below:

July 6, 2017 at 3:51 pm #61104quote amuller:Am I correct in thinking that all the long-shaft version of this would have the usual 5″ extension?Yes – all long shaft versions of these 33 and 28 HP models have the extension, and as you mentioned earlier, no thermostat or "Super Quiet" double exhaust housing. When you get to the next generation of 25 to 35 HP OMCs that started appearing around, I think, 1976, those long shaft models have a one-piece housing. FYI: The 33 in my photo a couple of posts back is a 1966 – like yours, a $50 motor. It pulls over with good compression feel, but I haven’t done anything with it yet, so don’t know if I have a restorable or parts motor – it came as a deal with several others where a friend of a friend was cleaning out after his Dad. It’s a ways down my priority list to get running. This summer it seems I’ve spent too much time fixing everybody else’s motors instead of working on mine.

Dave -

AuthorPosts

- You must be logged in to reply to this topic.