Home › Forum › Ask A Member › 1966 Johnson MQ-12a service manual

- This topic has 7 replies, 4 voices, and was last updated 2 years, 4 months ago by

crosbyman.

-

AuthorPosts

-

August 1, 2023 at 4:59 pm #278719

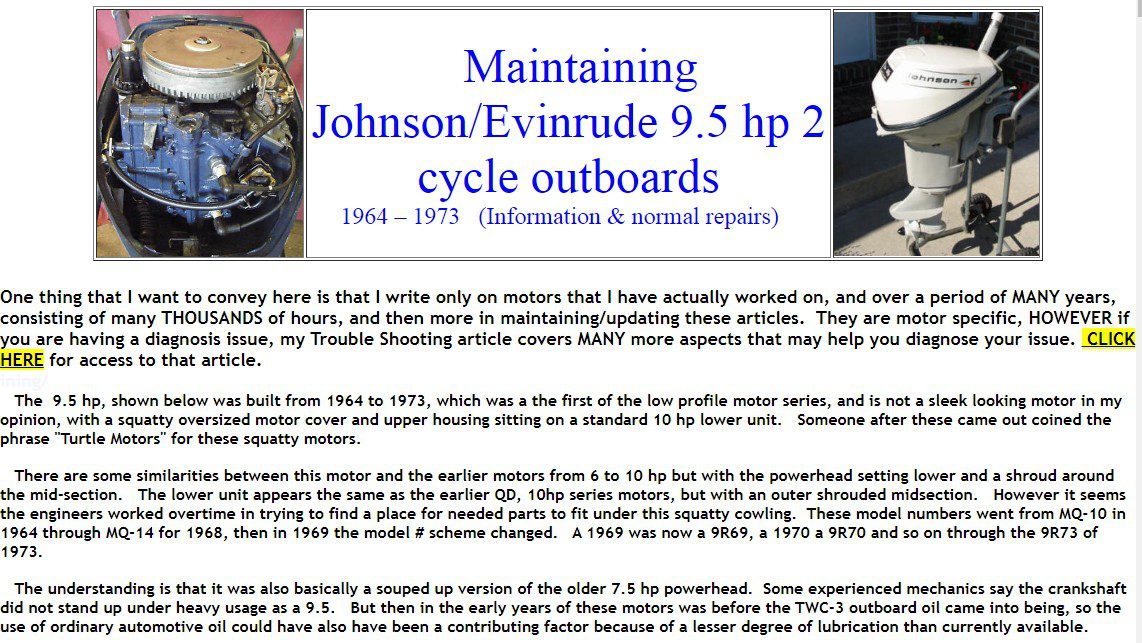

Working on a 1966 Johnson MQ-12a outboard. I am trying to find a service manual for this motor. Does anyone know where i can find a free download or a place i can go to for information. Primary looking for carb rebuild info.

Thank you Nick

August 2, 2023 at 6:24 am #278736Parts pages

https://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1966&hp=9.5&model=MQ-12Link to Service Manual pages on Fuel System (expires in 1 week)

https://we.tl/t-YJADmclSdVLots of good info on 9.5s here:

http://www.leeroysramblings.com/OMC_9.5.htmAugust 7, 2023 at 3:20 pm #278926Awesome Info thank you guys.

Next question, got the motor running after a though clearing of the carb. Motor runs well at half choke and when I close the chock it wants to cough then stall regardless of low speed setting. It seems like it maybe sucking air thru the low speed needle O-ring. From the diagram it shows an O-ring and a washer in which the the needle it self has a spring pushing against. Any ideas on how to correct this issue?

August 7, 2023 at 7:48 pm #278935idling requires a clean low speeb carb circuit did you the cleaning under the dime size plug see Leroy’s link above for details

check compression and post your numbers

Joining AOMCI has priviledges 🙂

August 9, 2023 at 8:07 am #279007There is a fixed high speed jet that is probably partially plugged. Was the carb dirty/gummed up when you cleaned it? Did you inspect/clean the high speed jet? Don’t attempt to remove it unless you have the proper tool. Trying to use a regular screwdriver will probably mess up the jet and damage the threads.

Is the oring and washer in place on the low speed needle, are the oriented properly? The initial low speed needle setting is about 1.5 turns out from gently seated.

August 9, 2023 at 12:46 pm #279010Checked compression 72 psi and 70 psi

Carb is very clean. When i tore it down it was not in bad shape fairly clean. When i start the motor and run at half choke its seems fine. When the choke is opened up it begins to cough. Tried the low speed needle adjust both in and out with not much luck. Started at 1 1/2 turns out and went out to 3 turns out. Then in to 1/2 turn still the coughing. If i push in on the washer on the low speed needle it seems to get slightly better. Could it be it is sucking air past that o-ring? The o-ring is seated correctly but it seem like an odd set up with very little compressing the o-ring to create the seal.

Thank you guys for the help on this one. I have three early 50’s Johnson’s i have rebuild so this one is pretty modern for me.

August 9, 2023 at 3:16 pm #279013I’m pretty sure there is supposed to be a spring behind that washer and oring to keep the oring sealed on the needle valve shaft.

OK, you have had the carburetor off, are you sure you got that crazy linkage back on properly? Is it possible that the throttle shaft is being held open by the linkage/cam being mis assembled? If the throttle shaft isn’t closing completely at idle, the engine will cough/spit and stall at low speeds no matter what adjustments you try to make.

August 14, 2023 at 8:15 pm #279230see pic

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.