Home › Forum › Ask A Member › 1967 Evinrude Lightwin won’t start/run

- This topic has 30 replies, 12 voices, and was last updated 5 years, 4 months ago by

joesnuffy.

-

AuthorPosts

-

August 20, 2020 at 11:39 am #212142

What is the compression 4 both cylinders. Also have you checked the mag for cracks? Hot coils may not fire.

August 20, 2020 at 3:48 pm #212166Thanks again for all the feedback, folks.

Fuel does run out the fuel line in a nice, steady stream if I remove it from the carburetor and open the petcock.

The reason I think the carb bowl is filling is because at least a couple tablespoons drain out of it when I remove the fuel line to take off the carb, every time.

Compression on each cylinder is ~70psi.

The plug wires are going to the correct plugs.

Stupid question, but is there a butterfly on the throttle arm ?

Not a stupid question at all, and oh gosh, I wish that’d been it, but alas, butterflies are visible and …flutter-able.. on both carbs. 🙂

I didn’t notice any cracks on the magneto when I took it off to replace the coils, condensers, and points.. Is there anything other than cracking I should look for?

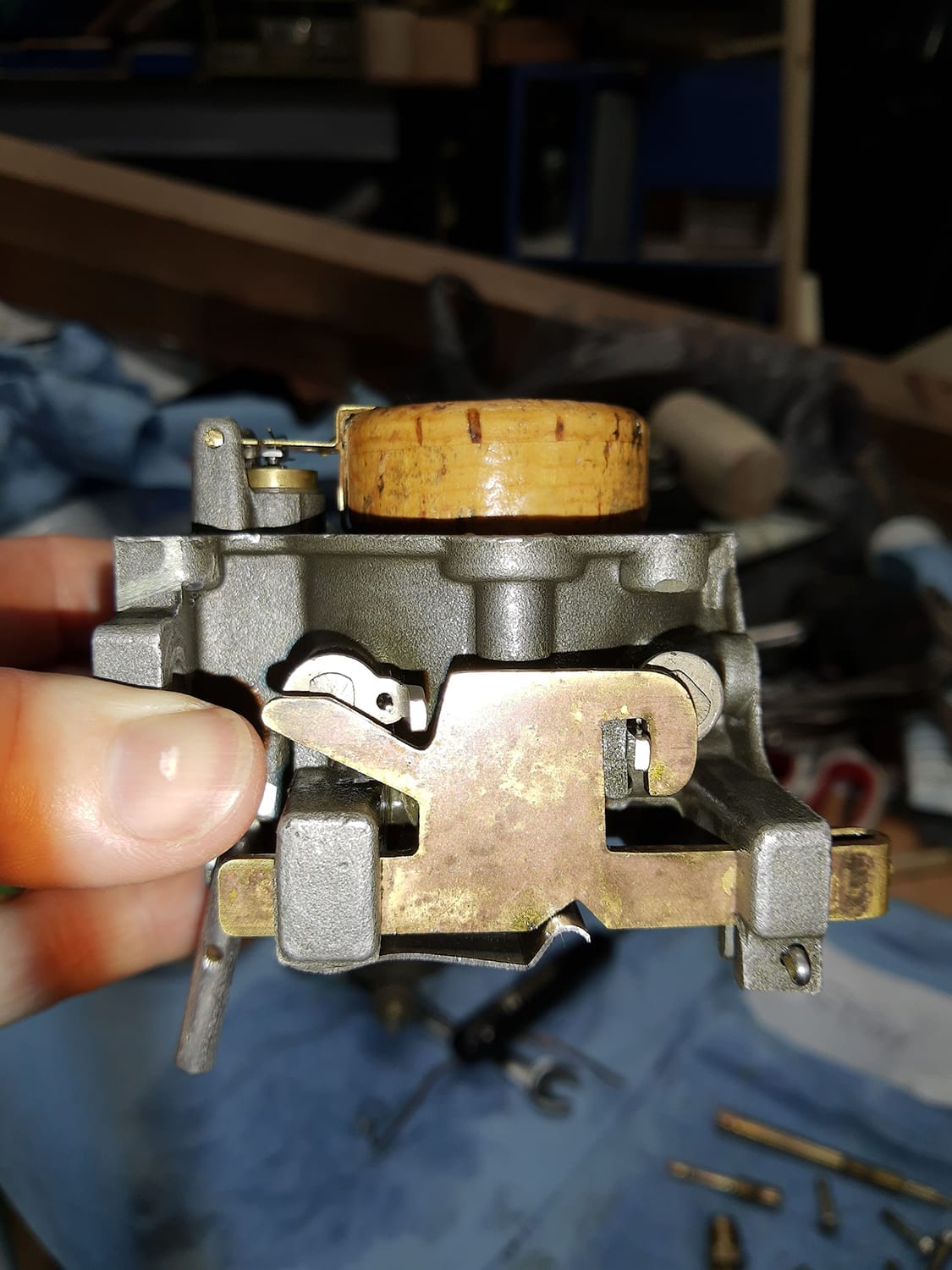

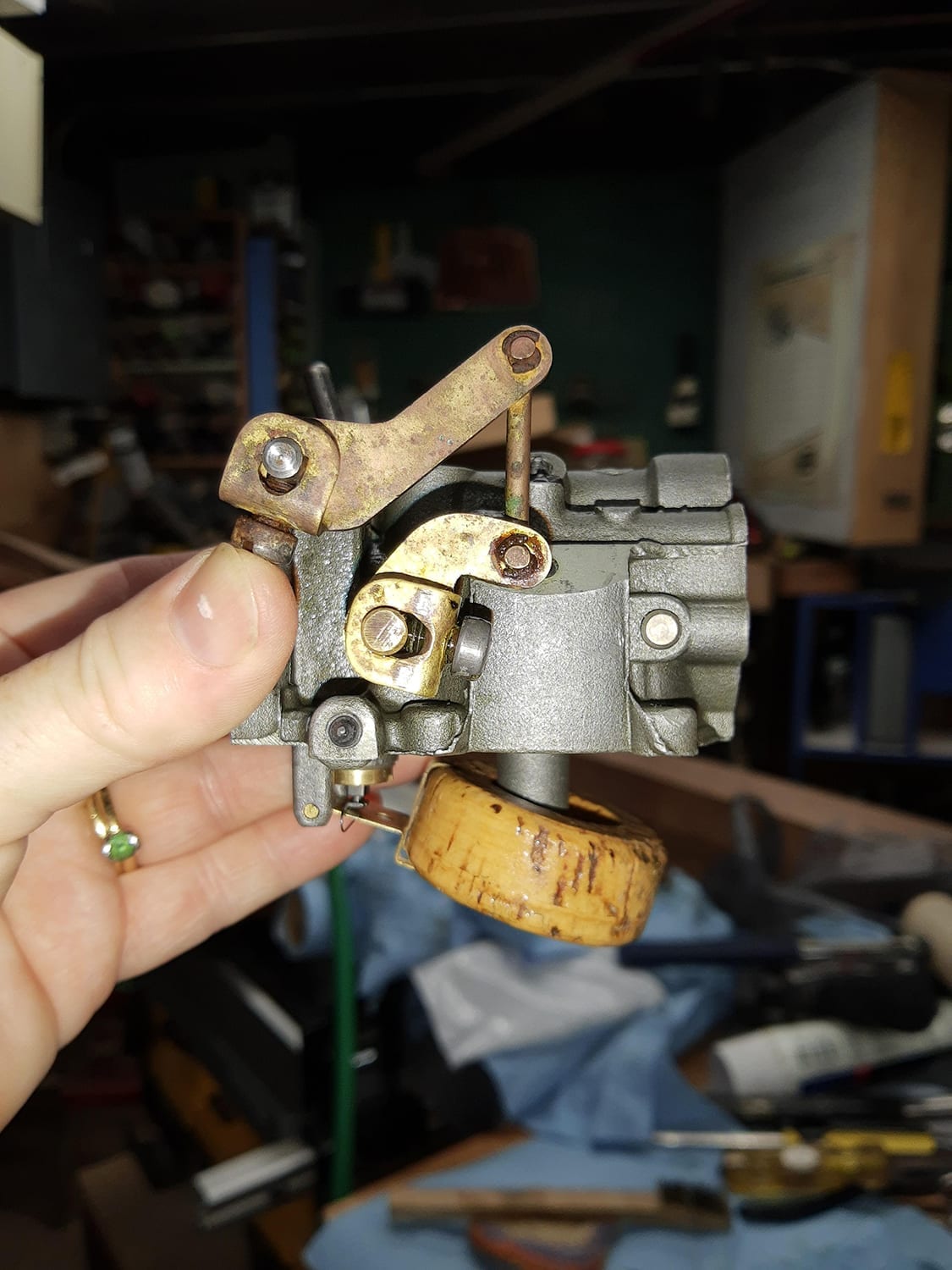

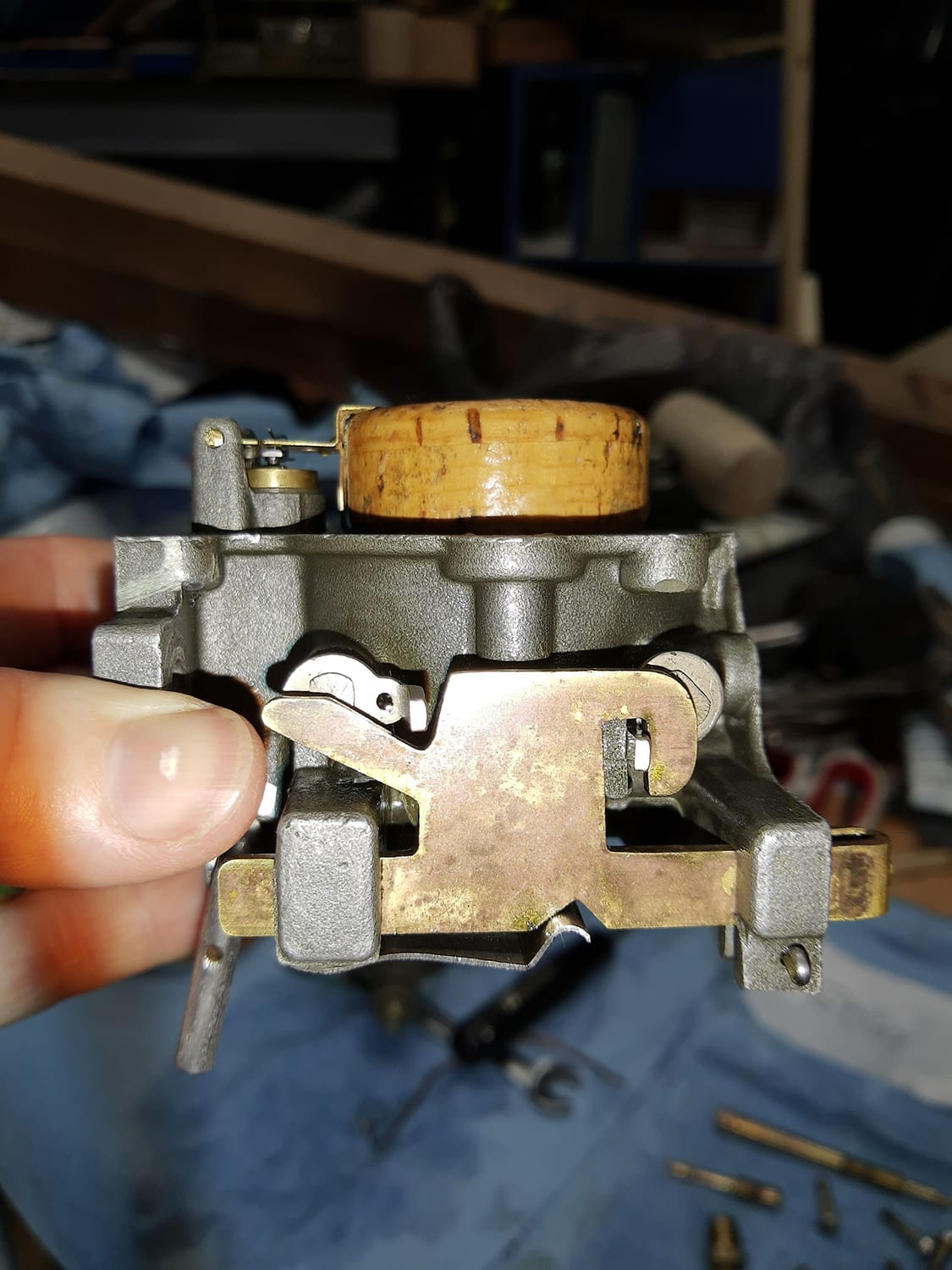

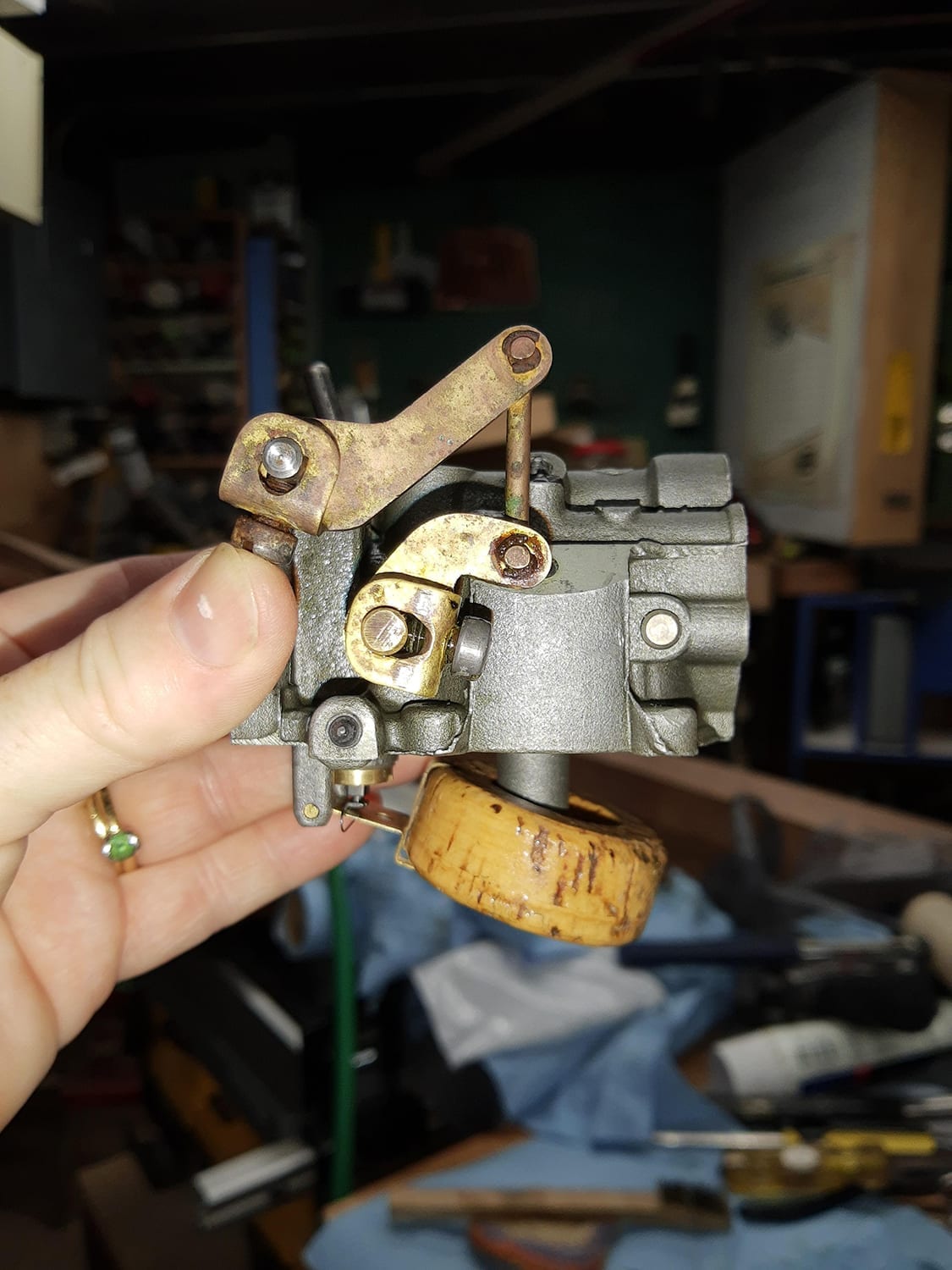

Last night, I disassembled both carburetors, soaked all the metal parts in Berryman Chem-Dip, rinsed with water per the instructions, dried with compressed air, and cobbled together one whole carb using my original carb body and the bowl from the ebay one. I used the cork float from the ebay carb, and it looks like this:

I did stick a little spare piece of unused fuel line on the fuel inlet and am happy to report that I can blow air through it upside down, but not right side up, so that feel promising.

I am now anxiously watching the clock for COB so I can go try it out.

-

This reply was modified 5 years, 4 months ago by

mierla.

-

This reply was modified 5 years, 4 months ago by

mierla.

-

This reply was modified 5 years, 4 months ago by

mierla. Reason: fix giant photos

-

This reply was modified 5 years, 4 months ago by

mierla.

-

This reply was modified 5 years, 4 months ago by

mierla.

August 20, 2020 at 3:55 pm #212178Sorry, couldn’t make the audio portion of your video work…

You have mentioned alot of things here, but may need more clarification…. Usually, if the only way to make the engine fire is squirting fuel/oil directly into the carb, then you have a fuel supply or carb issue. But, you mention good flow from tank and trying a different carb with no changes…

Sounds like someone messed around with your original carb, which had a fixed high speed jet by jamming an adjustable needle in the threads, which will never work out, and it is unlikely the engine would have run at all, but anything is possible. OMC did make an adjustable needle kit for that engine, but I’m pretty sure that would have included a new carburetor bowl. Perhaps you can post a picture of the old carb with the high speed needle installed. The conventional high speed needle would not fit through the lower cowls of that engine because there is no hole for the needle to pass through.

You mentioned that the engine was running, then the starter spring broke…How long was it before the you attempted to start the engine after the recoil repair? Did the engine sit long enough for the fuel to foul up? How did you check fuel flow from the tank? On your current carb, I would simply remove the lower drain hex plug from the carb bowl, then open the fuel valve and tank vent, fuel should dribble out of the bowl. If it doesn’t, then I would disconnect the fuel line from the carb and retest for fuel flow from the fuel line. You mention that you had the bowl off the current carburetor, did you remove the high speed jet? Did you look through the jet? Was it clean? If not, soak it in carb cleaner for a few hours. You need the special OMC jet screwdriver to remove the jet, trying to pull it off with a regular screwdriver will probably damage the threads, jet, and create more debris inside the carb bowl.

Sounds like you had the cylinder head off, the exhaust cover off, did you pull the powerhead off the midsection also?? Did you replace these gaskets, or reuse the old ones? You replaced the reed intake gaskets, please know that the two gaskets are different, and the engine probably won’t run if you mix them up. Finally, you were making some pretty violent changes to that low speed needle. The initial adjustment for the low speed needle is 1.5 turns out from gently seated. Is the needle valve pictured the one that came from the second carb, or was it transferred to this carburetor from the first one? The reason I ask is that perhaps the needle valve is damaged/broken.

Post pictures that will help clarify things for us. Again, the symptom you speak of is usually a fuel supply or carb issue, but you seem to indicate there is not problem with fuel flow to the carb and the engine doesn’t work even with another carb. So, I’m thinking we have missed something here, and made some incorrect conclusions…August 20, 2020 at 3:55 pm #212179Thanks again for all the feedback, folks.

Fuel does run out the fuel line in a nice, steady stream if I remove it from the carburetor and open the petcock.

The reason I think the carb bowl is filling is because at least a couple tablespoons drain out of it when I remove the fuel line to take off the carb, every time.

Compression on each cylinder is ~70psi.

The plug wires are going to the correct plugs.

Stupid question, but is there a butterfly on the throttle arm ?

Not a stupid question at all, and oh gosh, I wish that’d been it, but alas, butterflies are visible and …flutter-able.. on both carbs. 🙂

I didn’t notice any cracks on the magneto when I took it off to replace the coils, condensers, and points.. Is there anything other than cracking I should look for?

Last night, I disassembled both carburetors, soaked all the metal parts in Berryman Chem-Dip, rinsed with water per the instructions, dried with compressed air, and cobbled together one whole carb using my original carb body and the bowl from the ebay one. I used the cork float from the ebay carb, and it looks like the below photos.

I did stick a little spare piece of unused fuel line on the fuel inlet and am happy to report that I can blow air through it upside down, but not right side up, so that feel promising.

I am now anxiously watching the clock for COB so I can go try it out.

August 20, 2020 at 4:03 pm #212184OK, well that carb looks nice and clean…But, you can’t judge fuel flow into the carb by the few drops of fuel dripping out of the fuel line connection.

Seems like the fuel is flowing through the fuel hose just fine though, are you sure the tank vent is open and clean?

Is the carb apart now? Or still on the engine? If the carb is on the engine, try reconnecting the hose, opening the fuel valve and letting the bowl fill up…Now pull the hex drain plug from the carb bowl to see if fuel is dribbling out…August 20, 2020 at 4:45 pm #212186fleetwin, I just put the carb back on the motor, without the silencer.

As you suggested, I opened the vent and petcock to let the bowl fill, then removed the drain plug, and got a very healthy torrent of fuel.

Then I tried to start the motor again, with the low speed needle out 1.25 turns. It’s *very* close, much closer than my last attempt.

Here’s a video of my attempt, with some fiddling with the choke and low-speed needle.

I do note now that there’s some fuel visible in the throat body, and when I removed a spark plug, the cylinder behind it looked wet.

August 20, 2020 at 5:00 pm #212187OK, got the audio fixed on my laptop so heard your latest video fine. Again, you are confusing the issue by twisting that needle valve so violently. Set it to 1.5 turns out from gently seated, it will start and run that way. Sounds like it “wants to start”, but no quite… Try advancing the throttle closer to the fast position, may you will get it running that way…. At this point, it seems like fuel is flowing to the carb, and the carb is supplying fuel/air mix to the engine… The carb isn’t flooding over is it? You might see a little dribble coming out of the carb throat which is “OK”, but fuel should not be running out of the throat constantly. If you fear the carb is flooding, simply try to start it with the fuel valve closed.

1 user thanked author for this post.

August 20, 2020 at 7:07 pm #212203I have 2 of those same motors mine are 1952’s. I agree with Fleetwin I watched the video and it looks like you need to open the throttle more by rotating the throttle lever to your right if your facing the motor. Mine is marked Start I put the throttle lever to where it says Start/Fast. Once it starts and warms up a bit (or if water is being thrown out of your water bucket) you can slowly rotate the throttle lever to the left a little at a time until it slows down a bit and idles that’s where the idle screw comes into play that’s the one you were turning on. Do like Fleetwin said gently close it until it stops turning don’t force it or you will damage your needle valve then open it up 1 1/2 turns leave it there don’t adjust on it until you get it started and it warms up and even then it may not need adjusting it only is used to get it to idle very well. I will try and make you a video of mine tomorrow and how I start it and adjust it I think that might help you.

I also had one more thought that after re-reading what you wrote ” and when I removed a spark plug, the cylinder behind it looked wet” you might be getting water into one of your cylinders that could be the wet you saw and that’s what is keeping it from starting and running at a fast speed. Have you tried to start if for a few seconds like 10 seconds if it will start while its not dipped in the water tank your using. Try placing the throttle in the Start position and see if it will start and run and if it does cut it off around the 10 second mark. You would then know you got water entering one of the cylinders.

Joe

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

1 user thanked author for this post.

August 21, 2020 at 4:10 pm #212303Here are the videos I promised to make with my southern accent explanation I hope it helps. Turns out my low speed adjustment screw is 1/2 turn out from barely seated that is where mine idles the best. I didn’t even see how far out my high speed screw was because you don’t have one on your carb. If your high speed jet is working correctly yours should start in the start position or faster position. If you have water in a cylinder or both cylinders it will not start. I hope this helps you figure it out. If it were mine and wouldn’t start I would pull it out of the water pull the spark plugs take a shop vacuum and suck any water out of the cylinders put spark plugs back in and see if it will start in the start position or higher if it does its getting water in one or both cylinders don’t let it run long like that it won’t be cooling and its hard on impeller especially if impeller has been dry for a while. I hope these videos help.

https://www.youtube.com/watch?v=M4S5LD_yEjk&feature=youtu.be

https://www.youtube.com/watch?v=mIATNjjqKMM&feature=youtu.be

Hope this helps,

Joe-

This reply was modified 5 years, 4 months ago by

joesnuffy.

1 user thanked author for this post.

August 21, 2020 at 6:12 pm #212319Have you checked for spark? Take the spark plugs out, put the wires on them and position them so the metal body of the plug is touching the engine block – don’t worry about paint or a good connection – just let them touch. Then pull the starter and look for spark in the plug gaps.

If you have spark, then , yeah – all the carb stuff the other guys are talking about.

These models are known for blowing the headgasket, creating a path through the gasket between the cylinders, and then it will kick some but it will not start, but when this happens, the compression is usually lower than what you measured, but the compression is usually the exact same in both cylinders when this problem happens.

Dave-

This reply was modified 5 years, 4 months ago by

outbdnut2.

1 user thanked author for this post.

-

This reply was modified 5 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.