Home › Forum › Ask A Member › 1967 Evinrude Lightwin won’t start/run

- This topic has 30 replies, 12 voices, and was last updated 5 years, 4 months ago by

joesnuffy.

-

AuthorPosts

-

August 22, 2020 at 11:56 am #212355

I agree with outbdnut2 on have you checked for spark with the actual spark plugs if they won’t spark it won’t run. I know I read you checked with a spark checker I was using one earlier this week and its one of those neon type checkers I will post a pic of the checker I was using and it was flashing making me think I had spark but when I tried an actual spark plug no spark was being created. Turns out I didn’t have the flywheel key inserted correctly it is not a typical flywheel key on this particular motor its a tapered flywheel key so I did not have it lined up correctly with the points cam. That brings up a good point your flywheel key could also be sheered but checking for spark with the actual spark plugs as he mentioned is a must. That is the one thing you can do 1st when working on an outboard and if they are sparking great if not they have to spark to run and that must be investigated and fixed. You have sprayed fuel in the carb throat and it did not start you have compression in the amount of 70psi per cylinder you may not have spark on one or both the actual spark plugs.

On the motor you see running in my video I built my own electronic modules for it so it has no points or condensers in it now. I have them pretty well perfected now and bullet proof to use on the older OEM coils but that’s a different story.

Joe

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

1 user thanked author for this post.

August 24, 2020 at 3:14 pm #212505By gum, it’s running!

Thank you all, so, so much for all your kind help and suggestions.

And joesnuffy, thank you especially for the videos – it hadn’t clicked for me when each of those adjustment valves would matter and when they wouldn’t.

Per fleetwin’s suggestion, I set the low one at 1.5 turns, and the motor ran for a few seconds before quitting, on the first pull. Progress! SO much better than before.

And then, thinking about Joe’s videos and need2fish’s comment about the missing butterfly on the throttle arm, it dawned on me that when I put the throttle cam back on after replacing the leaf valves this last time around, maybe I didn’t get it snugged up enough and it’d shifted.

Sure enough, when I set the throttle at the notch on the cowling (which I learned about from another super-helpful thread here), there was a great big (well, visible anyway) gap between the cam and the cam follower shaft. They didn’t even begin to touch until the throttle lever was just behind where I was setting it to “start” the thing.

I adjusted the cam forward to where it was supposed to be, snugged up the bolts, left the low-speed valve just as it was before, and on the next pull the little motor started right up and kept right on running.

So it turns out at least one of the problems here was the person wielding the wrench and her imperfect understanding of how that little arm was supposed to work.

Again, thank you all for your guidance and this amazing resource.

Now that I’ve got it running, it throttles up smoothly, and seems to idle okay, but cuts about when the throttle is well ahead of the “slow” mark – is this likely to be a further cam adjustment, or is this where I would (gently, and more patiently than previously) adjust the low-speed needle to get it to idle even slower?

-

This reply was modified 5 years, 4 months ago by

mierla.

August 24, 2020 at 4:00 pm #212515By gum, it’s running!

Thank you all, so, so much for all your help and suggestions.

And joesnuffy, thank you especially for the videos – it hadn’t clicked for me when each of those adjustment valves would matter and when they wouldn’t.

Per fleetwin’s suggestion, I set the low one at 1.5 turns, and the motor ran for a few seconds before quitting, on the second pull. Progress!

And then, thinking about Joe’s videos and need2fish’s comment about the missing butterfly on the throttle arm, it dawned on me that when I put the throttle cam back on after examining the leaf valves the last time through, maybe I didn’t get it snugged up enough and it’d shifted.

Sure enough, when I set the throttle at the notch on the cowling (another very helpful thing I picked up from yet another helpful thread on this site), and actually looked at it, the cam was nowhere near the shaft. It didn’t even *nudge* it until the throttle lever was most of the way to the right, where I was trying to start it.

I adjusted the cam forward to where it was supposed to be, snugged up the bolts, and by golly, that little motor started up and kept right on running on the next pull. Seems I may have been starving the poor thing.

So I guess the motor had a few problems, not the least of which was the person wielding the wrench and her imperfect understanding of how it was supposed to work. Sheesh.

But! Now that it’s running, it throttles up nicely, and down to about halfway to the slow mark, and then dies, as seen here (I didn’t go all the way to the top here, lest I throw all the water out of my bucket, but I did later, once I had the hose at the ready to keep it filled up.)

Should I expect to get a slower idle out of it? My father’s regaled me with tales of somebody’s old Evinrude that idled so slow you could count the reps, but maybe that’s a bit of a fish story..

If it is possible to get it to idle more slowly, am I understanding correctly that *this* is when/where I would (more gently and patiently than before) adjust the low-speed valve needle?

August 24, 2020 at 4:21 pm #212519OK, good find on the throttle cam…Sometimes those stamped cams get bent bacwards/out of the way if the carb butterfly linkage is stiff or jammed. That throttle linkage must be “syncronized” properly. In other words, the carb butterfly should be completely closed (cam not touching the throttle lever) at dead idle, and it must start to open the butterfly at just the right time…I can’t remember where the throttle lever needs to be set on this engine when the butterfly starts to open, I’m sure someone will post the instructions. The engine will not idle properly if the butterfly is cracked open slightly at idle speeds, or will will run rough at mid range speeds if the the butterfly is set to start opening too late.

So, the first step is to check and adjust the syncronization, once someone kindly posts the instructions.

Once syncronization is set properly, I would put the engine on the boat, then try to adjust the needle. Warm the engine up at WOT, then slow it down to the lowest speed it will continue to run on its own…Set here, I would make very fine adjustments, try closing the needle 1/8 turn and let the engine run a bit…If quality improves slightly, then close the needle another 1/8 of a turn and continue this process until the engine starts to falter.

If the engine runs worse when you first close the needle 1/8 turn, I would try opening it 1/8 turn and repeat the process described above. Make sure that packing nut is fairly snug so the needle is a little tough to turn…Not too tight, but snug. You don’t want the needle packing to be too loose or the needle witll turn on its own and could suck air through the packing nut.

Finally, you need a higher water level in that tank….The water level should be above the gearcase/exhaust housing joint. Running the engine with the low water level in your video could destroy the rubber water pump impeller…1 user thanked author for this post.

August 25, 2020 at 8:33 am #212581I agree with fleetwin the lower unit needs to be a little lower in the water try putting something under your water bucket or a deeper bucket. You wouldn’t want the motor not to be circulating water that could burn it up by overheating it when running.

Your motor actually sounds like a decent idle with the lever in the middle of the range which as fleetwin said it may need a tad of syncing (the throttle cam may need adjusted to come out a bit more where it rides on the butterfly shaft or the butterfly shaft might need bent (especially if someone before you bent it) in a tad if throttle cam is already all the way out to get yours to idle with the lever in a slower position but it actually sounds like decent idle so I suspect your slow speed adjuster is pretty close) I don’t have the manual for that motor but someone reading it will. What makes this motor a little different than a lot of newer motors is it stays in gear. You can rotate the motor 180 degrees when its on the boat for reverse. Having said that they idle a tad higher than a newer motor that is capable of not being in gear when idling. When yours is on a boat and the boat is moving on the water it helps the motor to run a bit slower because the boats movement is helping the prop to keep moving at a more constant rate at lower speeds.

I hope that helps,

Joe-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

1 user thanked author for this post.

August 25, 2020 at 9:03 am #212590Okay, thank you. I’ll put some cinder blocks under the bucket to raise it up for my next attempts, and hopefully get it on the boat sometime this week.

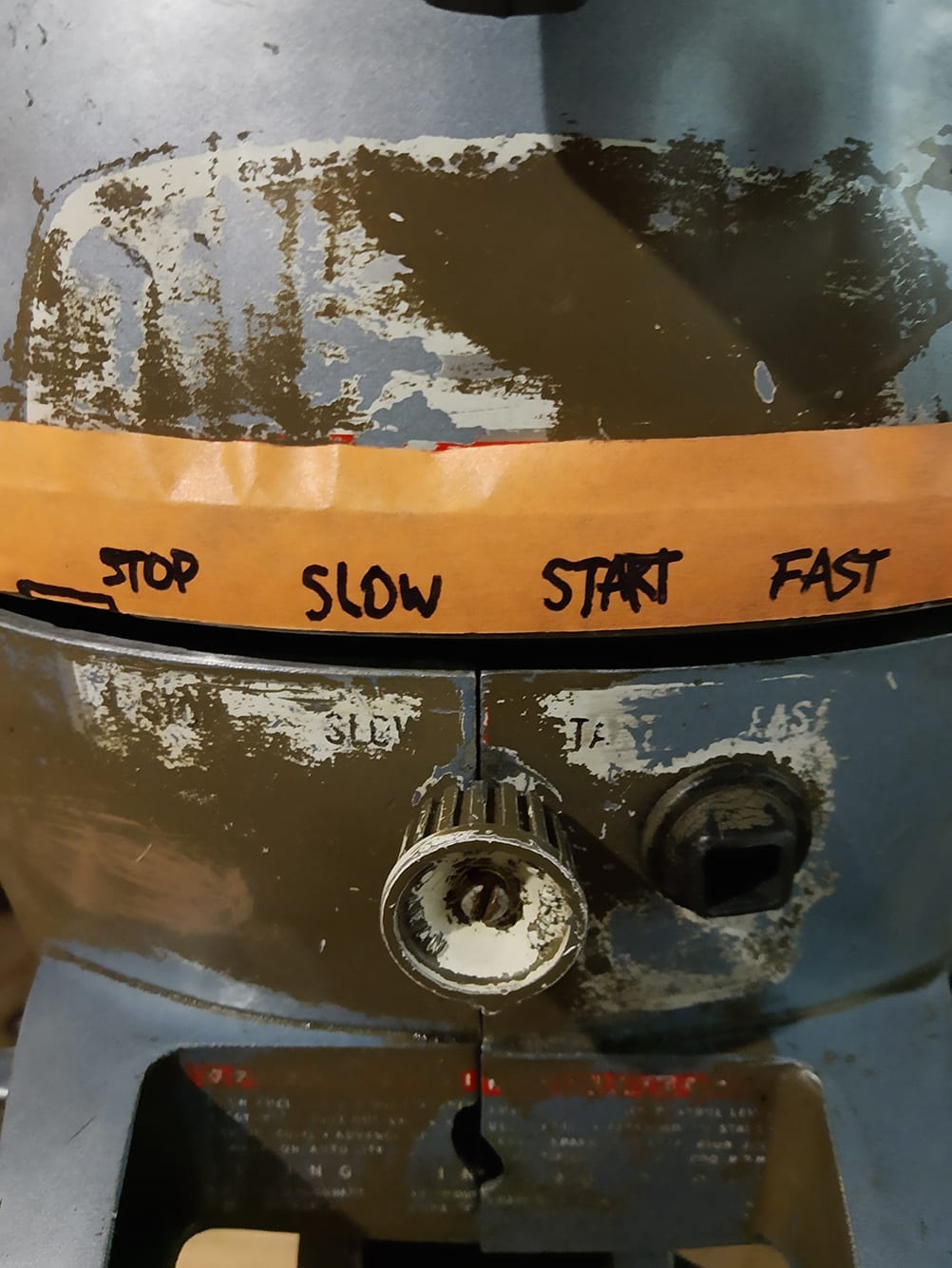

Thunderstorms kept me from testing it again last night outside, but I did manage to carefully strip a little more of the faux-duckwin paint off of the lower shrouds so I could make out where the stop/slow/start/fast marks actually are. They’re much closer together than they appeared to be on your motors, joesnuffy, and a lot closer to the middle than I thought they were. I had Start about right, but I’d thought the others were much further to either end of the throttle control. I marked the notch for the cam synchronization, too.

August 25, 2020 at 9:40 am #212600That’s good research on your speed marks and yours are closer to the middle than mine are. I just saw your link https://aomci.org/forums/topic/1966-evinrude-lightwin-3-hp-carb-sync/#post-17447 and I think your magneto cam and cam follower on the carb are set very close to where they should be. If your motor is capable of running high speed then your probably good-to-go because I know it will run slow speed.

I do run NGK B6S spark plugs in mine and they seem to make it run better at lower speeds without fouling they are a tad hotter. I use these spark plugs in a lot of my older outboards that don’t have thermostats because they are a tad hotter and I get better results. https://www.sparkplugs.com/product.aspx?zpid=9235 I had made a mistake on spark plug link but its right now.

The actual manual says to run it with the low speed screw turned out at 1 1/4 you have yours set to 1 1/2 so your in the ball park on the low speed setting.

Good Job,

JoeThe link I accidentally put for the Champion J6C #823 (https://www.sparkplugs.com/product.aspx?zpid=8593 is the replacement plug for Champion J6J of yesteryear to the best of my knowledge and it can be modified into a champion J6J. I read in an old service manual from the late 40s early 50s that the J6J plug has a shorter top electrode which is filed down close to the center of the center of the bottom center electrode I have modified newer champion J6C and J4C spark plugs like this before when they are what I have because it makes the fire jump from the center electrode at an angle to the top electrode helping to prevent fouling. I am not suggesting you do this but it is interesting.

In my pic you see the arrow and you would file the top electrode back to the other vertical line I have drawn in pic making the top electrode a bit shorter. Being careful not to file the center electrode whatsoever only the top electrode.-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

-

This reply was modified 5 years, 4 months ago by

joesnuffy.

1 user thanked author for this post.

August 25, 2020 at 10:56 am #212610What I originally wrote has just fell off on this topic but good job on the research with your lever position. I think if your motor will run at high speed your good-to-go. Your idle speed is close to the center and it is idling well while its close to center. As you stated my idle speed is further to the left facing my motor its a 1952 yours is a 1967 things change. Your in the ball park with low speed adjustment set to 1 1/2 since manual link you provided in an earlier post calls for 1 1/4 I heard yours idling and it sounds very similar to the way both of mine idle.

Good Job,

Joeps Just make sure its circulating water well especially if you just changed the impeller which I think you said you did. You wouldn’t want to overheat it especially when you got it going now..

August 25, 2020 at 4:53 pm #212645Thanks again, Joe. Not sure I would ever have gotten there without you folks’ help. This site and its members are such an incredible well of knowledge.

That’s really interesting about the spark plugs. What I’ve got in there right now are Champion J6C, but I bought some extras, so maybe I’ll dig out a file and give the mod a try, if I get brave/confident enough.

ps Just make sure its circulating water well especially if you just changed the impeller which I think you said you did. You wouldn’t want to overheat it especially when you got it going now..

Oh yes – I changed the impeller, and cleaned out the channels around the exhaust chamber and cylinder head, so water should have a clear path around the powerhead, I think…

I fired it up again (Hurrah! Two days in a row!) during my midday-take-the-dog-out break today, having raised the bucket and water level, and was pleased to see mist and little jets of water spitting out of the eight little holes in the lower half, so that means the impeller’s working properly, right?

August 25, 2020 at 7:39 pm #212650Mieria what/where is the lead shot you referenced. Thanks.

Ah to be young and foolish again instead of old and still foolish.

-

This reply was modified 5 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.