Home › Forum › Ask A Member › 1968 18 hp evinrude

- This topic has 15 replies, 9 voices, and was last updated 9 years, 7 months ago by

jerry-ahrens.

-

AuthorPosts

-

March 23, 2016 at 2:48 am #33816

I wouldn’t rebuild the fuel pump unless you know for a fact that is the problem .It can be pretty tricky to do. Set the low speed needle at around 1 turn open from lightly seated and adjust for smoothest running at low speed.

Turn the lights down low and hold the plugs against the block while spinning the flywheel (clockwise) with a socket driver in a drill. Look for nice snappy spark alternating between plugs . Spin it for a while and see if it is consistent. Even if it is, the points may need to be cleaned and gaped. If there is a cover plate on top of the flywheel remove it and see if the coils are cracked, in which case they will have to be replaced.

You can get a cheap compression tester From Harbor Freight for about $25.00 , or better yet borrow one. Take out both plugs and wind in the tester into one plug hole, with both plugs grounded, pull the rope until the needle stops climbing and take the reading. Do the same in the other hole and hopefully you will find less than 10 percent difference between them at around 110psi if I remember correctly what my 18 hp runs nicely on. I could be missremembering though

I am wondering if the throttle linkage is hooked up right.

Here’s a link to a parts diagram.

http://www.marineengine.com/parts/johns … 1968&hp=18

March 23, 2016 at 3:10 am #33817

Cory, it certainly seems that the carburetor is part of the culprit, but your motor has sat for a while and the ignition may need looking into.You can get a open gap spark checker at just about any auto parts store or on amazon for about $6 to $8 dollars.

Here is a video showing how to assess spark with an open gap checker on an 6hp Johnson. The process is the same for your motor. In the video it is hard to see the spark because filming was done in full sun light.

https://www.youtube.com/watch?v=p7w0xW48YCU

The next post below will have a lot of information, but please lets evaluate one section at a time. Let start off with spark. The rest of the information posted will be available for you to review as we go through the systems. Your grandfather’s motor has sat for a while, so it really needs a good evaluation. You can do it with guidance from the members.

March 23, 2016 at 3:11 am #33818– There is a process for evaluating the motor. If you are willing to take guidance we can help you out to determine what is going on with your motor.

* First thing is to check the compression yourself. Most auto places will loan out a compression tester for a deposit and money is refunding when you return it. Napa, Auto Zone, O’Reilys…etc.

Here is a video to show you how you can test your compression.

https://www.youtube.com/watch?v=PyCw4SiuT2I

Please report back your finds on compression.

**Second phase of diagnostics is to evaluate the ignition.

***Third phase of diagnostics is to evaluate the carburetor fuel delivery.By putting the spark plug against the engine block is not adequate assessment of the health of the ignition system. You need to get a spark checker and gap it to at least 1/4 inch. The spark should be able to consistently jump the gap and be a strong blue snapping spark.

Here is a bunch of information that you can read and do the repairs yourself and know what is going on.

Here is some information that will help you evaluate your ignition system with the flywheel popped off.

Harmonic balance flywheel puller video

https://www.youtube.com/watch?v=Nz1st4XnsX4

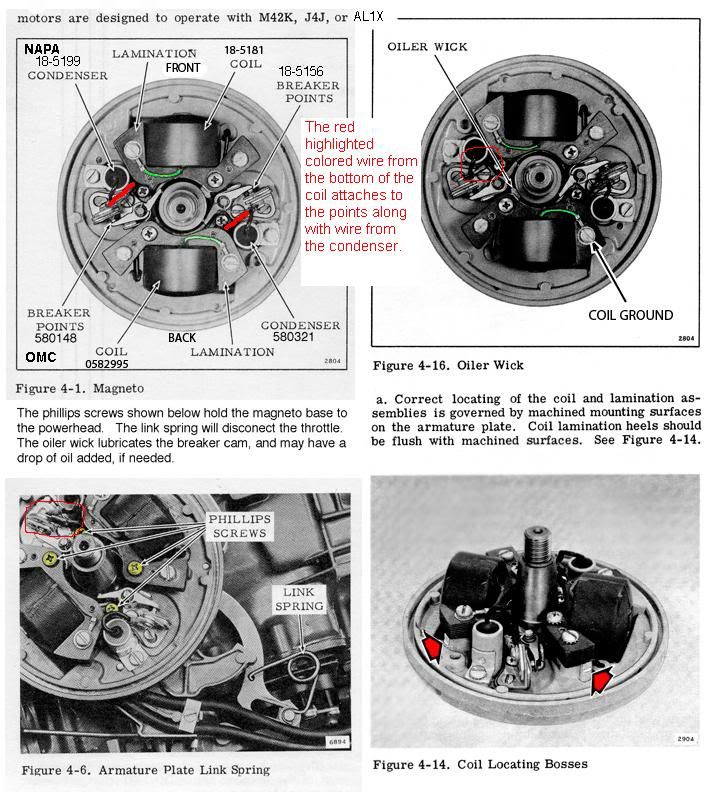

Your going to need to inspect your points, condensers and coils. They are located under the flywheel. Hopefully all you need to do is clean and regap your points and you might be in business. Still check your coils and condensers and plug wires.

Here are two link to show you how to test your coils and condensers.

http://www.youtube.com/watch?v=KT8rk5QWgS0

http://www.youtube.com/watch?v=l6eSXYmENDY

How to replace your coils, points and condenser. Please take digital pictures as you go, so it will help you return everything back in the right order. Keep cheap zip lock bags available to put your parts in so you don’t lose them. They are small.

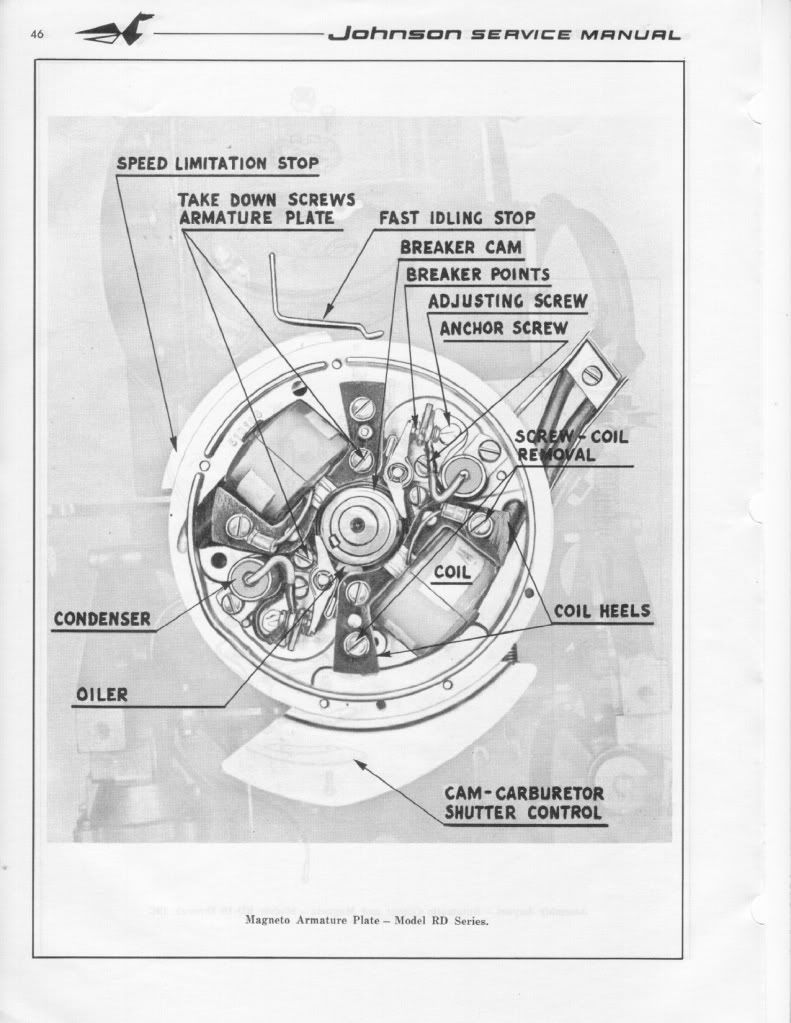

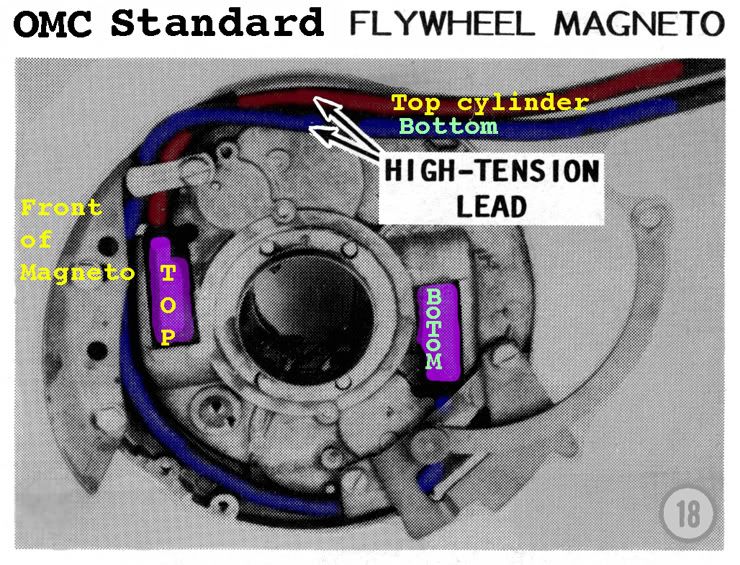

Here is a diagram of a generic OMC (Johnson/Evinrudle/Gale) ignition assembly. You will have to remove the coil designated for the top cylinder and put the oil wicker in. It should be already be coated with a very light oil. (not grease). The purpose of the oil wicker is to lightly lubricate the outside riding surface of the points cam so the point shoes do not prematurely wear. If you look at the points they have little shoes that ride along the cam. Please make sure the (breaker)points cam is on the correct side or the ignition will be out of timing. It should have the word top machine written on the side facing up.

FYI: You can only set(gap) one set of points at a time. Put the flywheel nut back on(turn with a wrench or ratchet clockwise) to allow you turn the crankshaft. (Please remove both spark plugs to make it easier to turn the crankshaft and prevent accidental starting)

You gap the point to 0.020 when the point shoes is at the top(high point of the cam). It should have a mark along with the word top. Then you will turn clockwise to the next set of points (180 degrees) and set those points the same way. You will notice that the point of the previous set will be closed and when you come around again they will open up. *** When they are open no current is allow through. This is how you set your timing with the points.***

When you go to set the point’s gap. Very gently snug the anchor screw, then adjust the points by the adjusting screw and the feeler gauge until the feeler gauge is sliding through with slight resistance only. Then tighten the anchor screw. Repeat procedure with second set of points. Please make sure your hands are clean and the feeler gauge is clean, because oil on the points can foul them up and create resistance….poor or no no spark. ALways use a spark check to evaluate spark. It should jump minimum 1/4 inch. Blue sharp snappy spark.

Here is a picture of a spark check…Cheap $6

Here is a picture of how to tell which wire is going to the correct cylinder. Thanks to Garry for providing the picture on other post.

If your using the existing wires then cut about 1/4 inch of end going to the coil, so you have clean un-oxidized copper contacting the spiking in the coil. Twist the end of the spark plug wire onto the coil spike. If you have replaced the wires, make sure they are 7mm copper metal core and not the automobile stuff.

***** Please make sure two things*****

1.) Make sure all the wires are tucked away under the flywheel and not rubbing up against the cam or crank, because they will eventually get damaged and create a short, then no spark!!

2.) Make sure the coil heels (ends) are evenly lined up with the mounting boss.

Here are some pictures. (Compliments of JBJennings..nice fella)

Lining up the coil heel with the mounting boss prevents damage of the coils and the flywheel magnet, prevent rubbing as the flywheel turns.

*** Make sure the throttle is advanced to that start position***

Here is another picture that Garry (thanks Garry!!) supplied on another post with some modification.

Both diagrams, should answer your questions.

Here is some you tube videos that can help you diagnosis and properly setting your ignition and clean set your carburetor

Here are a bunch of videos that can help you along. They are long and detail, but I purposely made them that way, so someone new to motors would feel comfortable. So, I apologize if they are boring. I originally made those videos to help a guy who had little mechanic knowledge.

Here is a link on how to remove a flywheel.

https://www.youtube.com/watch?v=Nz1st4XnsX4

Here is a bunch of links to evaluate and repair your ignition

If your looking for a help cleaning your points and testing your ignition, then here are some YouTube videos that can help.

Not professional videos, but they can help guide you through ignition diagnostics and repair. The motor in the video is a 1968 Johnson 6hp.

Hopefully will give you a visual and help you some.

Evinrude Gale and Johnson ignition video 1

https://www.youtube.com/watch?v=oTN8Ag_aj-8

Evinrude Gale and Johnson ignition video 2

https://www.youtube.com/watch?v=r7A6d8me0Gw

Evinrude Gale and Johnson ignition video 3

https://www.youtube.com/watch?v=ZAlT32NnTJ0

Evinrude Gale and Johnson ignition video 4

https://www.youtube.com/watch?v=re6FgcB_Yok

Evinrude Gale and Johnson ignition video 5

https://www.youtube.com/watch?v=ClGt6xHnb94

Evinrude Gale and Johnson ignition video 6

https://www.youtube.com/watch?v=taaSzp1Ev-0

Evinrude Gale and Johnson ignition video 7

https://www.youtube.com/watch?v=p7w0xW48YCU

Here is a bunch of links to help you with your carburetor.Here are some videos on how to clean and apply a carburetor kit for an OMC high speed fix jet carburetor. Displayed motors are 1968 Johnson 6hp and 1964 Evinrude 18hp outboards. The videos are very long and over detailed, but I want to help those who are new/novices to motor repair. Again, I am no expert or certified marine mechanic, but I am offering video to help.

OMC fix jet carburetors part 1 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=7MmDOaOQyQg

OMC fix jet carburetors part 2 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=PuByx8J-EfY

OMC fix jet carburetors part 3 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=FpivbGEv0wM

OMC fix jet carburetors part 4 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=-aWICvsQZQ8

OMC fix jet carburetors part 5 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=JqB6PLqeTI4

OMC fix jet carburetors part 6 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=HS5J_AxJrAY

OMC fix jet carburetors part 7 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=Iq_2RfWjQ28

OMC fix jet carburetors part 8 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=-lXIVBX_UF4

OMC fix jet carburetors part 9 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=-nA_4YmNgt8

OMC fix jet carburetors part 10 of 10 (Motor displayed 1968 Johnson 6hp)

https://www.youtube.com/watch?v=94lcU7y2P9Y

Almost forgot to post an accessory video regarding a timing fixture. You can certain set the points with a feeler gauge as shown in the previous videos, but I just wanted to add this to the list.

https://www.youtube.com/watch?v=eNK2TEeQQv0

Carburetor Adjustment for idle/low speed needle. Your carburetor has a high speed fix jet, so no adjustment. It just needs to stay clean.

Initial setting is: Slow speed = seat gently(turn in clockwise), then open 1-1/2 turns(turn out counter clockwise). Do not tighten or force the slow idle needle shut or it may damage the needle.

Start engine and set the rpms to where it just stays running. In segments of 1/8 turns, start to turn the S/S needle valve in (clockwise). Wait a few seconds (10 to 15 sec) for the engine to respond. As you turn the valve in(clockwise), the rpms will increase. Lower the rpms again (turn your throttle slightly slower) to where the engine will just stay running.

Eventually you’ll hit the point where the engine wants to die out or it will spit back (sounds like a mild backfire). At that point, back out(turn out counter clockwise) the valve 1/4 turn. Within that 1/4 turn, you’ll find the smoothest slow speed setting.

When you have finished the above adjustment, you will have no reason to move them again unless the carburetor fouls/gums up from sitting, in which case you would be required to remove, clean, and rebuild the carburetor anyway.

March 23, 2016 at 3:33 am #33819Cajun,

That should keep him busy for a while! Excellent job with the presentation of that information. Well done.

March 23, 2016 at 10:19 am #33822I have a 59 Evinrude 18hp that had the same symptoms you are describing. Changed plugs, rebuilt carb, same problem. It turned out on mine it was cracked coils. It idled ok, but had the jerky miss or cough like you describe. When I tried to accelerate the motor the spark just scattered and faded. 2 new coils and she ran like a champ.

March 23, 2016 at 10:38 am #33823I suspect that your low speed needle is out of adjustment. If the low speed needle is open to far the engine will immediately flood out. Not open far enough will cause an immediate bog. Turn the low speed needle in GENTLY untill it’s seated, then back out 3/4 of a turn. The low speed needle should be no more than 1 full turn open. This will give you a starting point, and allow you to run the engine in a barrel. Allow the engine to warm up completely, then at idle, slowly turn the adjustment needle in, untill the engine coughs, then back it out [slowly] untill you obtain a smooth idle. If the carburetor has been rebuilt by someone, chances are they used an aftermarket carb kit. I would suggest going to an Evinrude dealer and get the OEM kit and do it the right way. Follw Don’s advice and make sure that high speed jet is clean. If the low speed needle turns easy and won’t hold an adjustment, you can try gently snugging up on the packing nut, located right where the needle enters the carburetor. This may just fix your trouble.

Take a look at the carburetor bowl gasket. You can see it protruding out, where the two halves of the carb bolt together. If it’s a darker brown color, then you may be ok. If it’s a brighter yellowish color, then it’s aftermarket and your carburetor should be removed, cleaned and rebuilt with an OEM kit. I might get yelled at here, but I hate aftermarket carburetor kits! They have made me chase my tail many times trying to track down a weird running problem. -

AuthorPosts

- You must be logged in to reply to this topic.