Home › Forum › Ask A Member › 1980S Evinrude 7.5 re-coil problems

- This topic has 15 replies, 5 voices, and was last updated 5 years, 9 months ago by

JACQUES.

-

AuthorPosts

-

May 1, 2020 at 4:20 pm #201658

This may be a late 70s motor, the recoil works until I set it in place and then it seems to stick. If I help it by hand it will move but it’s almost as if it’s rubbing the whole time. When I tighten the bolts down at the top it won’t move at all. Any help would be appreciated.

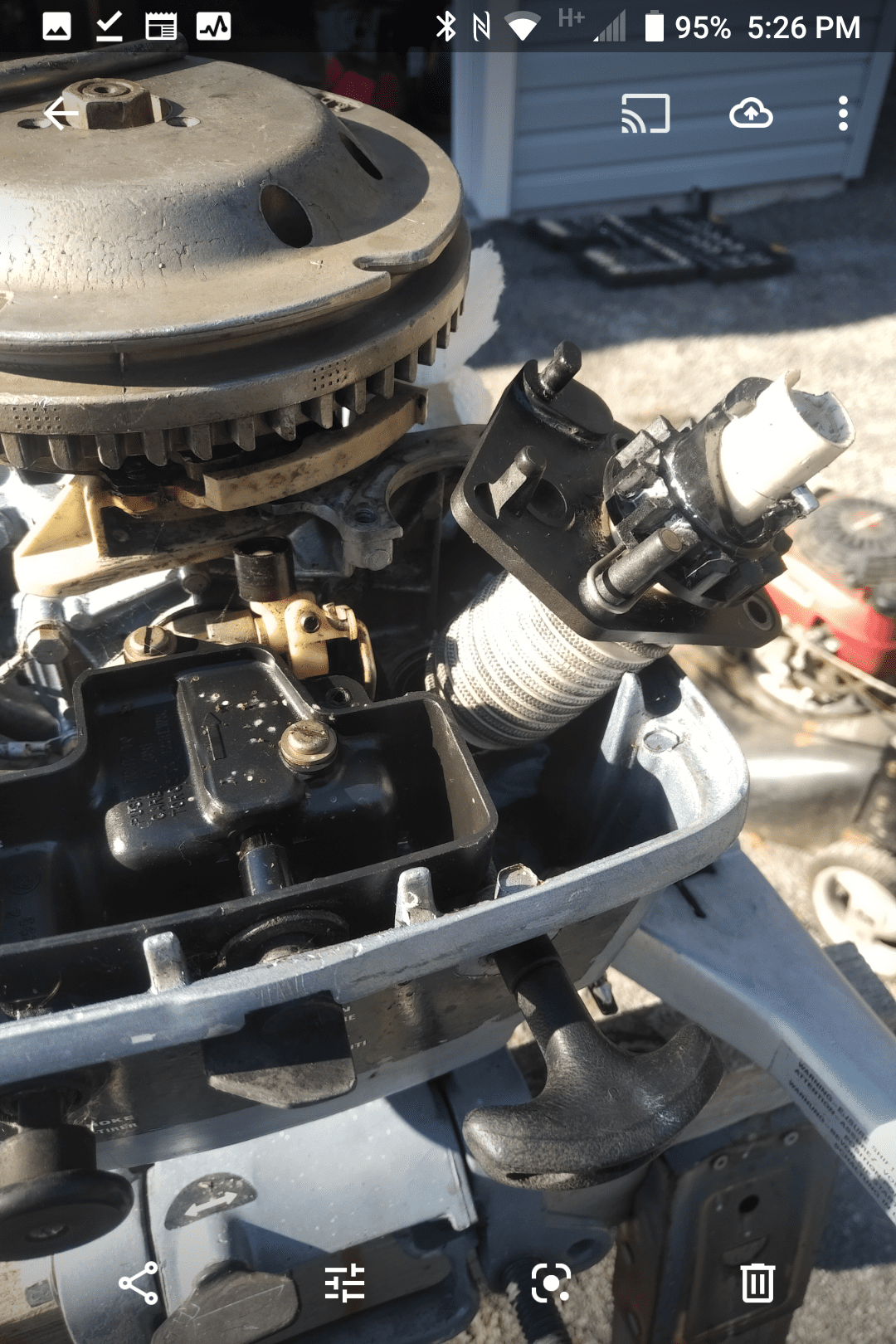

May 1, 2020 at 5:29 pm #201667Here are the vitals of the motor and a look at where I’m at in this job.

-

This reply was modified 5 years, 9 months ago by

Mumbles.

Mumbles.

May 1, 2020 at 5:49 pm #201674OK, first tell us how this issue occurred…Did you have the starter apart? Did you replace the rope? If you replaced the rope, the rope knot is probably binding on the vertical aluminum rope guide.

That knot has got to be “just so” or it will interfere with the rope guide. I don’t think the safety interlock would keep the rope from retracting properly, but perhaps.

There is a little plastic bushing that seats the plastic rope pulley drum into the lower housing, these often get damaged/misinstalled during reassembly also:

http://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1980&hp=7.5&model=E8RCSS&manufacturer=Evinrude§ion=Rewind+Starter-7.5

Item#2

Sometimes the black upper housing does not get seated into the aluminum guide during reassembly: items #14 and 7, this can cause the drum to bind also…May 1, 2020 at 8:03 pm #201683Okay thanks for the tips, for starters your right about the knot. I’ll look at that first and go from there.

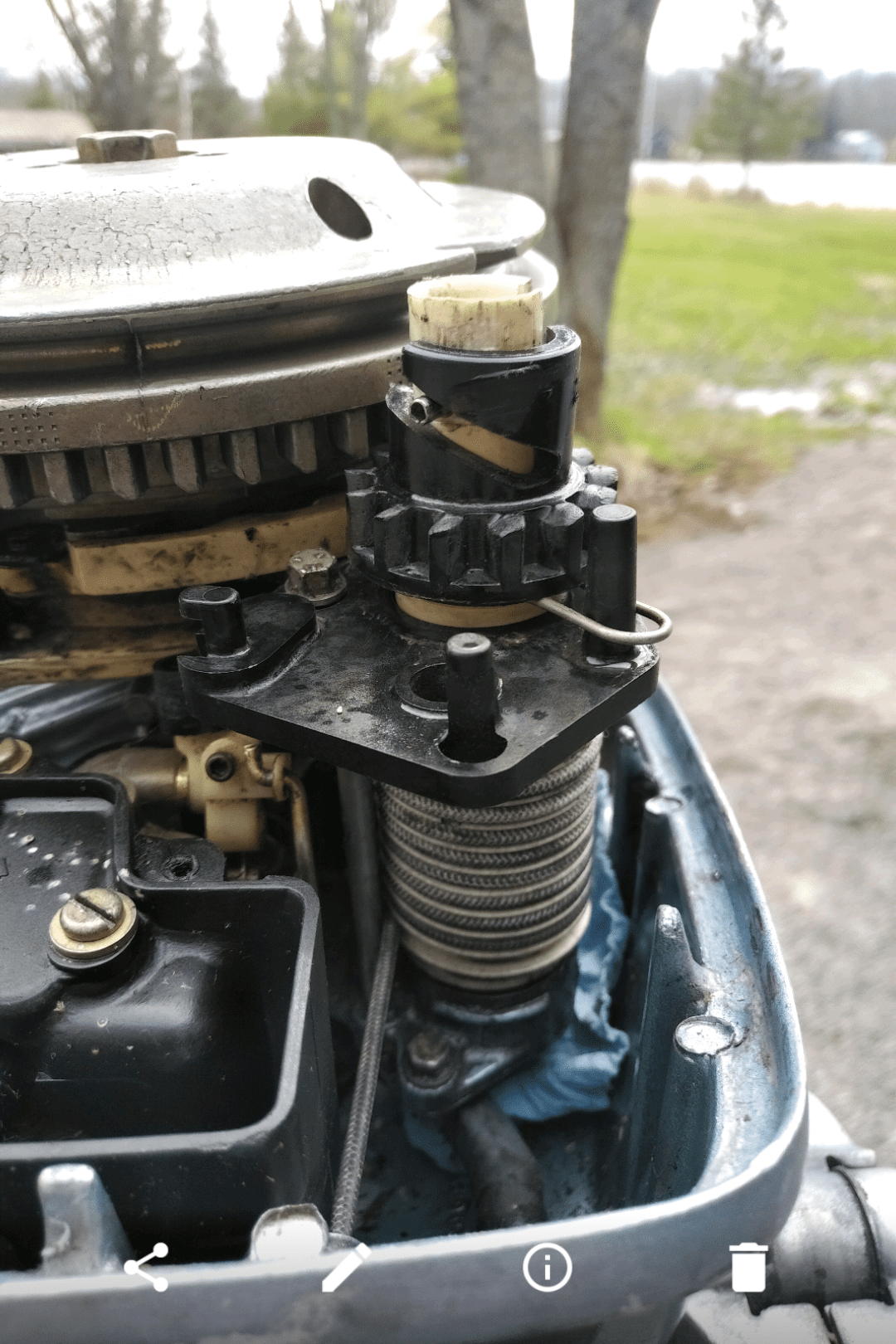

May 2, 2020 at 3:26 pm #201760Okay so I have re-installed everything and wound the recoil again. The knot is now tucked in neatly to the recoil but It is still jamming up. When I loosen the bolts that hold it in place it snaps back fast. Here is a picture, do I have the black think on top lined up correctly?

-

This reply was modified 5 years, 9 months ago by

Mumbles.

Mumbles.

May 2, 2020 at 8:30 pm #201792I have had that issue before. My fix was to put two washer sunder the black “plate” and then push bolt though the plate then washer. This is

to hold it up higher when tightened down by the two boltsMay 3, 2020 at 8:47 am #201813Okay, certainly worth a try Michael, I’ll see if I have any washers I can slide under today, maybe that will help.

I did check the plastic bushing at the bottom Don, it does not seem to be a problem. I’ve done one of these re-coils before and found that problem, the plastic on the bottom splits and breaks off and it won’t hold a wind anymore. This one is okay, I’m not 100 percent sure I’ve got the guide rod in the right place, it could be too tight, but the black housing fit over it pretty well. I’ll check that today, always harder to look this stuff over with a couple of toddlers running around you all day!

Anyways thanks for all the suggestions. On a side note I did get the chance to take the kids for a small ride yesterday buy wrapping a rope around the flywheel. It ran really good once started for a motor that has sat around for a while. I replaced the head gasket and the water jacket gasket over the winter, if I can get that re-coil going, I’ll do the impeller and have a pretty good motor I think.

May 3, 2020 at 6:33 pm #201925that pull rope looks pretty hefty… is it the proper size

Joining AOMCI has priviledges 🙂

May 3, 2020 at 6:43 pm #201927I think it is the proper size, either way I don’t think it is inhibiting the motion of the recoil. Could the spring be broken or sticking?

May 4, 2020 at 8:18 am #201959OK, so you have removed the interlock, so that is not an issue. From what I can see in your picture, the aluminum rope guide seems to be correctly positioned indicating you have the top bolted down correctly….

The other issue I was referring to is a little plastic bushing that fits in between the white plastic pulley and the lower spring retainer plate. You mention the “fork” at the bottom of the pulley that retains one end of the spring, so I’m not sure we are talking about the same thing….

So, you loosen the bolts just slightly, then the rewind works fine. That seems to indicate that there is no the plastic rope drum has no end play between the upper and lower starter brackets. This seems counter to what I would think, I would have thought that wear over the years would increase end play. But, these are plastic parts and may have warped or expanded somehow. I guess the simplest thing to do is try to wobble the while rope pulley up and down vertically to see if our guess is correct (with the bolts tightened).

Again, did this issue just occur? Or did it occur after you had the starter apart for some reason, including just moving it aside to remove the carb….

Finally, is this engine used in salt water? If so, you will want to consider pulling the powerhead to inspect/change the upper water tube grommet….It is important to get these gearcases off frequently, the driveshaft splines love to seize up into the crankshaft. Fortunately, gearcase removal/installation is easy on these engines because there is no shift rod connector to mess with… -

This reply was modified 5 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.