Home › Forum › Ask A Member › ’24 Elto Spun Flywheel

- This topic has 11 replies, 5 voices, and was last updated 8 years, 10 months ago by

slim60.

-

AuthorPosts

-

March 1, 2017 at 4:19 am #6437

When I first pulled the flywheel on the ruddertwin I could see by the chipped keyway that someone did not torque it down properly. At the time I did’nt realize the other problems that would arrise. After hours of cleaning, polishing, paint, honing cylinders, and a coil rebuild I started my reassembly. I first noticed the timer was rubbing on the fuel tank. Maybe the fuel tank was changed as it looked good and did’nt leak? I removed the coil hangers to lower the tank and that seemed to remedy that. Maybe I’ll take a little material off the bottom of the fuel tank mounts? Then the new flywheel key was touching the timer so I ground a little off. Today it started on the first bump but the timer moved to the left so I pulled the flywheel again. There must be so much wear on the crank top and or flywheel that I cannot torque it down without it coming in contact with the timer. I read here about refinishing the two surfaces to mate them tight. Could I then shim between them to raise the flywheel about 0.0020"? Or do I need a new crankshaft? I was proud of my resto and posted pics on "Current Projects" but this is discouraging. Any suggestions would be deeply appreciated.

March 1, 2017 at 8:58 am #53666.

If it was my motor………. 😎

I would take some very thin copper plate material

wrap it ( one time ) around the cone, just enough to lift the flywheel a little

keep it simple !, and……. I have seen this before, it sure works 100% 😉

.March 1, 2017 at 2:31 pm #53676

Overnighting does more that just make the flywheel go down farther.

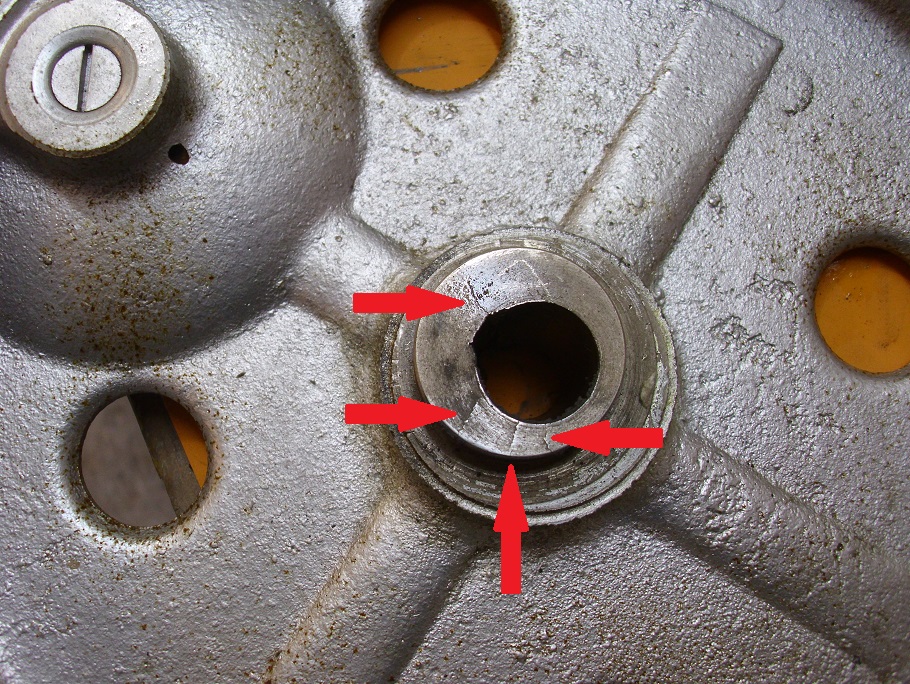

Check the flywheel exocentric closely for cracks.

If the flywheel is still OK you may be able to remove

some material from the timer. If you take it off

the bottom though you may be back to your gas tank

clearance issue but you could remove some material

from where it rubs the tank.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

March 1, 2017 at 6:22 pm #53691Kees, I see how the copper plate would work. And being softer than steel it will compensate for any imperfections in the taper. But as Tubs pointed out the exocentric is cracked. Could it be welded?

March 1, 2017 at 7:09 pm #53692Unfortunately I cannot recommend welding of any flywheel hub.

The likelihood of a successful weld repair on an iron casting like that is about zero. Almost guaranteed that the crack will spread, or show up in a place it wasn’t before after the casting has cooled. I wouldn’t trust it even if it didn’t crack right after welding. Flywheel hub that is cracked usually only means one thing – time for new flywheel! Most likely candidate is a flywheel from a donor parts motor. There are some repairs that can be attempted on a ruined hub, but I’m not sold on that approach. Not yet anyway…

Hope this helps, sorry if it doesn’t…

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

March 1, 2017 at 7:18 pm #53693.

that flywheel crack could be welded, of course, but I don’t know what the best way / option is.

If it was mine , I would try it myself, grind a little groove and weld it again

with a cast iron electrode or something but I am not

advising you, it’s very tricky.

looking for an other flywheel ? if available somewhere

btw. I like Tubs idea

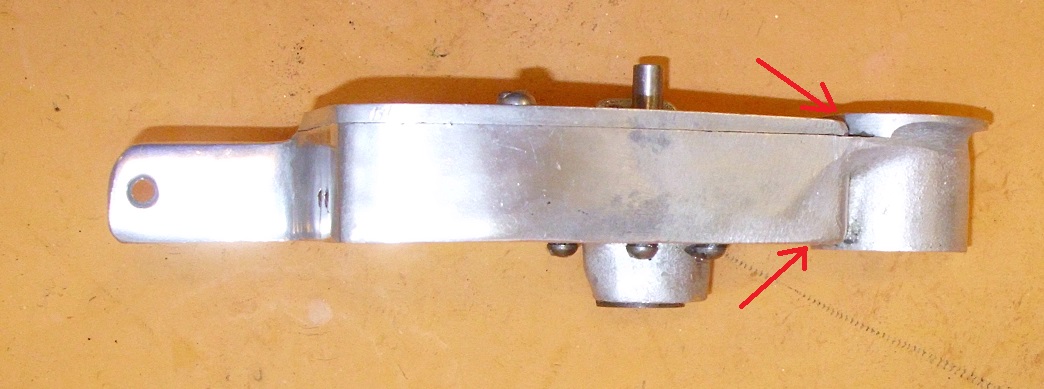

.March 3, 2017 at 8:09 am #53754I know where there is a Super Elto Model G Ruddertwin (1926 model) that has about a two inch diameter circle of cap screws round the flywheel nut. When I first saw it I assumed that the eccentric and/or key way must have been damaged and a new replacement had been machined and fitted. I may be wrong, but what else could those cap screws be fitted for?

I only wish now, that I had asked the owner what had happened to the motor to require those cap screws. Unfortunately the owner died years ago, but I could contact his widow and see if she or any of the family know. The motor is still in the family to the best of my knowledge.

MonteNZ

March 4, 2017 at 3:09 am #53793Thanks MonteNZ; It’s nice to know there may be an alternative to a replacement flywheel. I talked to my son last night and he said he has welded cast iron. He also knows how to stop a crack from migrating out from the center after it’s welded. We’ll see how it goes.

March 4, 2017 at 9:38 am #53796Hi Slim60

I phoned this afternoon and left a message for a chap to contact me next week and hopefully I will

find out some more about what happened to the motor and how it was repaired. I will put a post

up as soon as get the info.MonteNZ

March 4, 2017 at 1:42 pm #53806There are some real challenges here besides

just welding cast iron. The welds are going

to have to withstand the outward pressures

of the crankshaft that caused the cracks in

the first place plus the cracks have been

contaminated with oil. Still you have nothing

to loose and if successful your son would

deserve a couple of -At-A Boys- and at least

one -You Done Good.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.