Home › Forum › Ask A Member › 1928 Elto Speedster timer

- This topic has 17 replies, 4 voices, and was last updated 9 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

May 18, 2025 at 11:22 am #296535

Hmm…well, something must be out of alignment because when I actuate the shaft and hear the click, there is no movement at the points.

How is the brass bushing adjusted so as to achieve proper “alignment”?

May 18, 2025 at 1:52 pm #296542

Watch this video. https://youtu.be/fSqQE4CWe34?si=aA5BFIVyiMu6aVHC

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

May 19, 2025 at 10:00 am #296554I did watch that video the first time you posted it. It looks like you cut a shaft and inserted it from the bottom of the bushing to demonstrate how it actuated ghat little lifter. Thanks for that. It helped alot.

The brass/ bronze bushing which houses that shaft has no adjustment, correct? It is simply mounted to the timer housing by way of 2 screws through the bottom of the housing.

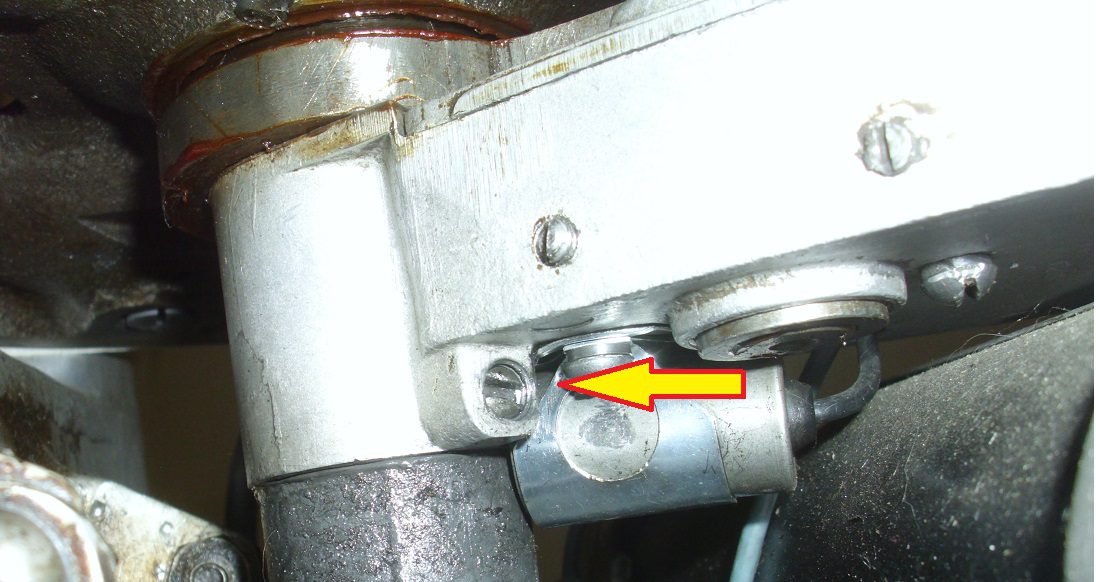

On the side of the timer housing there are 2 tiny set screws. What is their purpose? One of them came out easily but the other one is stuck rock solid and one side sheared off during attempt at removal. As a side note, I have a functional timer from a 1925(?) C model and there are no set screws on the side of that timer housing.

May 19, 2025 at 12:40 pm #296558

No adjustment for the brass bushing. I believe the screws you mention are to make minor adjustments as to where the points snap as to the location of the knob on the flywheel. That’s just a guess as I never could see where moving the mech. really made a noticeable difference. I only have Speedsters and Folding Lightweights. They may be of more value on other models. They may be just to hold the point mech. in position. Just tighten the one that’s free. It will move the point mechanism against the other that’s froze.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

May 19, 2025 at 10:29 pm #296570

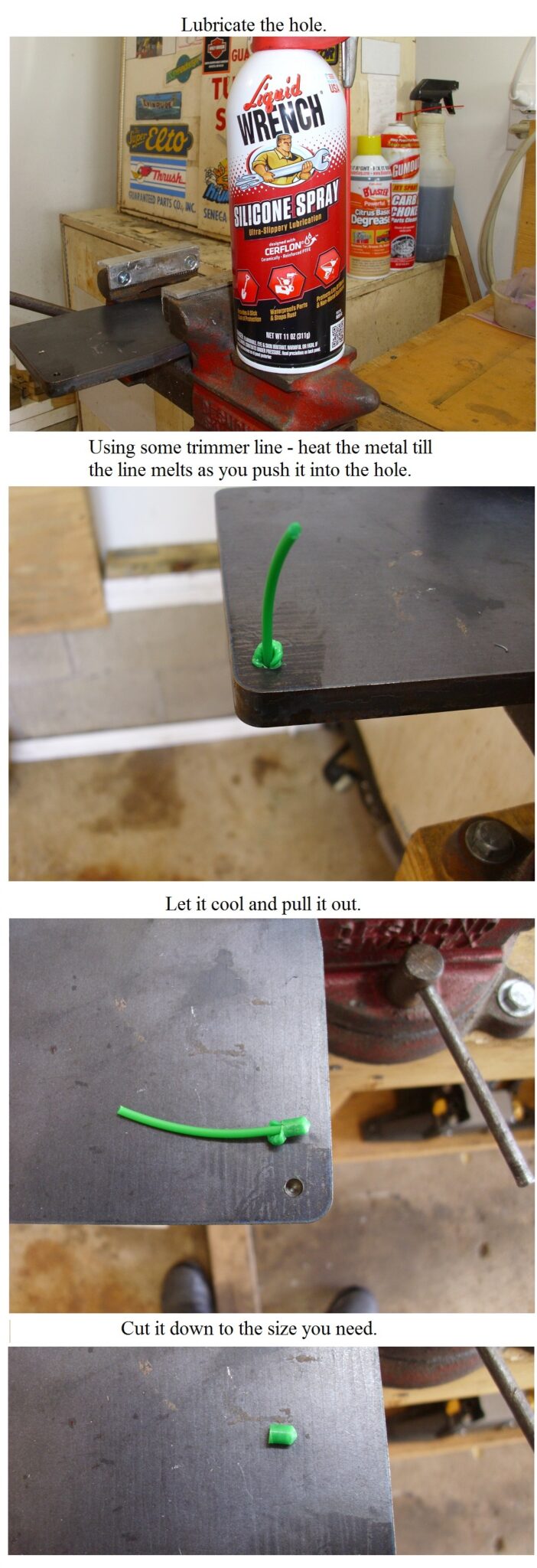

This is another screw that also gets stuck. It keeps getting tightened as the friction material wears down. When it bottoms out, it gets stuck. Then when you try to back it out half of the head snaps off. I used to make plugs from trimmer line (boathouse repair) to move the screw back out some, but now I just snip off a piece or two and drop them in the hole. Seems to work OK.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

May 21, 2025 at 7:36 am #296592

I quote this as I had made a comment and **POOF** it disappeared. never to be posted… ugh

http://www.richardsoutboardtools.com

classicomctools@gmail.comMay 21, 2025 at 9:48 am #296593

It may appear in the future (Reverse Poof!)- maybe not.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.