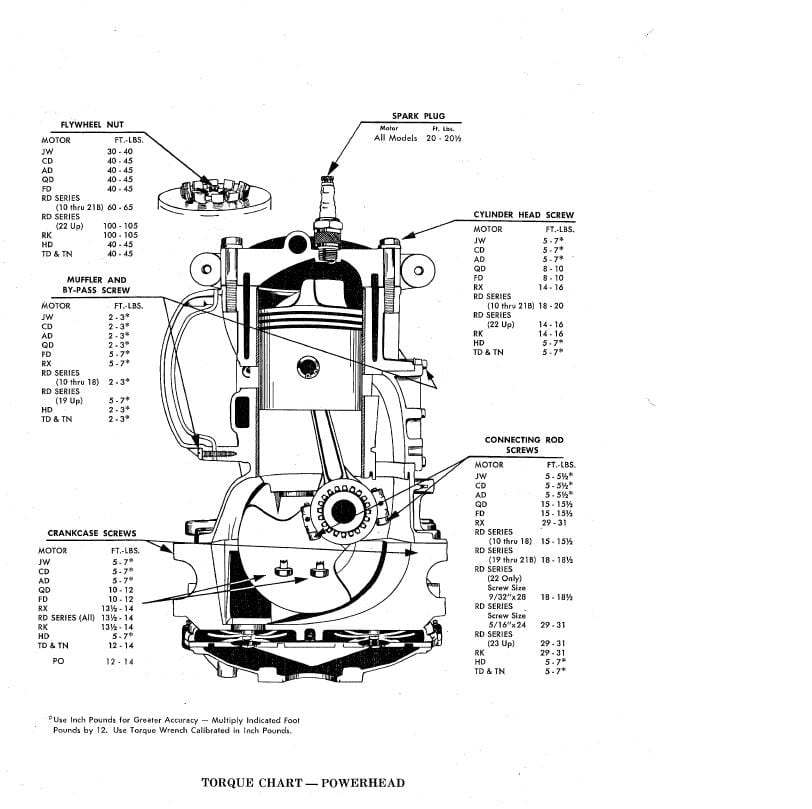

This chart shows 5 – 5.5 Ft Lbs but I’d go with inch pounds for better accuracy, 60 – 65. Since a 1/4″ drive socket seldom fits on the bolts without grinding it down, I use a screwdriver with a square shank and snug them up with a wrench on the shank before folding the locks over. Since I can’t get a torque reading this way I just guesstimate it.