Home › Forum › Ask A Member › 54 Johnson RD15A top seal (still) leaks

- This topic has 47 replies, 9 voices, and was last updated 9 years, 6 months ago by

joesnuffy.

-

AuthorPosts

-

September 9, 2015 at 9:00 pm #23544

OK, well how about spraying WD40 into the vertical crankcase groove that channels excess oil down to the horizontal groove/vacuum port. Spraying WD40 into the vertical groove should eventually lead to seeing WD40 spilling out of the vacuum bleed port that is visible with the carb removed. What do you think of this idea/theory?

September 9, 2015 at 9:01 pm #23545My guess would be a poor seat where the spaghetti seal abuts the bearing. Maybe cut too short, sealer dried up, etc…, and it is running up between the halves?

OLCAH, can you see where the leak is coming from?

September 9, 2015 at 9:16 pm #23547quote Chris_P:My guess would be a poor seat where the spaghetti seal abuts the bearing. Maybe cut too short, sealer dried up, etc…, and it is running up between the halves?OLCAH, can you see where the leak is coming from?

This is the type of situation that might be exposed by trying to pressurize the crankcase (with piston covering ports). Although I would think that you will see bubbles around the outside of the bearing normally, because there is no oring there.

September 9, 2015 at 9:20 pm #23549After taking the carbon seal apart a couple of times I don’t think the oil is coming thru the seal as there is not much oil under the carbon near the crankshaft. The carbon ring is down on the bearing as it should be, no sign of anything holding it up. If the drain was blocked with old oil or whatever, then the drain would not work and the oil would come out through the vertical slot.

September 9, 2015 at 9:23 pm #23550Here is a video Mumbles made of how he found a seal was leaking.

September 9, 2015 at 9:35 pm #23551Would fleetwin’s suggestion work. If I just sprayed a puddle of WD40 on top of the carbon seal, that should run down the vertical groove and then run down and drip out of the hole in the intake. If it does that, then maybe the problem would be crankcase sealing as Chris P suggests. If it does not run out of the hole I could take the intake apart as Frank has done and put a small wire into the passage to the bearing?

Thank you all and especially Frank.

September 9, 2015 at 10:21 pm #23555Watch Mumbles’ video and give it a try. But, I think it will be normal to see oil "blowing by" between the bearing case and the crankcase because there is no oring there.

But, doing this might point out an inop carbon seal, or perhaps a crankcase sealing problem.

Did you try spraying WD40 down the vertical groove? Did it come out of the vent hole inside the manifold??September 10, 2015 at 1:15 am #23573quote gjonz:Just curious Frank…Is that oil collection groove where the o ring on later motors is to go as well? I’ve seen some with annoying on that bearing and some without?

Or I could be an idiot too!

Greg

To be honest, I have to look at the parts books to see if it is supposed to have an o-ring. Of course if the case is split all one has to do is look for the presence of the oil return hole.

September 10, 2015 at 2:54 am #23580Frank,

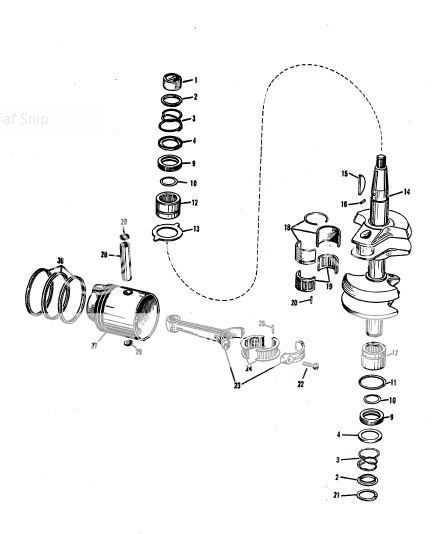

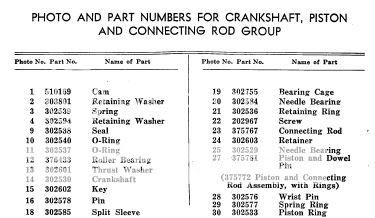

Thank you for taking the time to take this motor apart and send the photo’s. Very educational and enlightening. The old adage of a picture being worth 1000 words holds true.

September 10, 2015 at 4:03 am #23583There’s no outer O ring on the upper bearing, only the 302540 inner O ring inside the carbon seal. I’m sure it’s installed correctly but is the lip on the carbon seal facing the bearing and what is the condition of the bearing face?

-

AuthorPosts

- You must be logged in to reply to this topic.