Home › Forum › Ask A Member › 54Evinrude Big Twin crankcase

- This topic has 38 replies, 13 voices, and was last updated 9 years, 8 months ago by

adam1961.

-

AuthorPosts

-

February 24, 2016 at 3:44 am #32439

David,

I took readings before disassembly. Had a sore shoulder but got 94-95 PSI in both cylinders.

CharlieFebruary 24, 2016 at 2:01 pm #32450I’m just reading the post. I see filthy gasket surfaces & if I’m correct you haven’t honed the bores or used a taper mike to look for run out in the bore. How about the pistons? scoring, ring land wear, wrist pin clearances / bearing wear & ring wear. My first build was a 48 Dodge flathead 6. The new rings were so tight it would lock up after it was warmed up. It sure didn’t burn oil but we drug it backwards in reverse to get it loose. Your motor seems to be in rebuildable shape but you need to check clearances & clean gasket surfaces. What kind of threads are you going to use on the plug hole. I have a Evinrude 1954 15hp too. Great motors & easy to build.

Have fun!!February 25, 2016 at 1:43 am #32485Well, those scores concern me. Yes, I have seen similar conditions with no major piston scoring/scuffing, or stuck rings, but not very often. Kind of hard to judge piston condition with only one port visible through the exhaust chamber.

February 25, 2016 at 1:57 pm #32496I did not expect to be looking at a rebuild of the engine when I started to replace the upper bearing o-ring. I have never done one but as there are no oversize pistons/rings I need to take a few measurements to maybe see if the bore is saveable. At least I can take inside calipers and check for taper in the working section of the bore to get a feel for clearance w/o removing the crank/pistons. Seems like a short block if available would be a better alternative. More to come.

CharlieFebruary 25, 2016 at 7:18 pm #32505Took an inside caliper as I do not have inside mikes. I did not feel any taper from top of the piston travel to just above the ports. I am pretty sure that if I tried to hone the scratches out, the bore size would be increased more than 0.005 inches. The scratches are at least 0.005 deep. That would make the block unusable anyway.

Seems there are two choices:

1. Just put it back together and see if it runs ok. I will have to fix the stripped spark plug thread in the head. I have a new head gasket.

2. Look for a good short block.

Any comments or advice?

ThanksFebruary 25, 2016 at 7:40 pm #32506Pull the exhaust and intake covers to get a better look. If the pistons aren’t too bunged up, and the rings are free, I would probably give it the 50 cent hone job with emery and run it…..

Will it be perfect, no. But, these engines are pretty forgiving, and run amazing well even with some damage. The alternative is boring oversize and hunting down oversize pistons/rings, and it doesn’t seem like you are that committed to this engine to make the big expense of time and money….February 25, 2016 at 8:12 pm #32509I have NOS oversize pistons and rings for your motor if you wanted to go that way. Both .020 & .040. We can bore your block for you also. Just thought I would offer if it will help you make a decision. Your motor will be like brand new as far as piston to cylinder wall fit.

Dan in TN

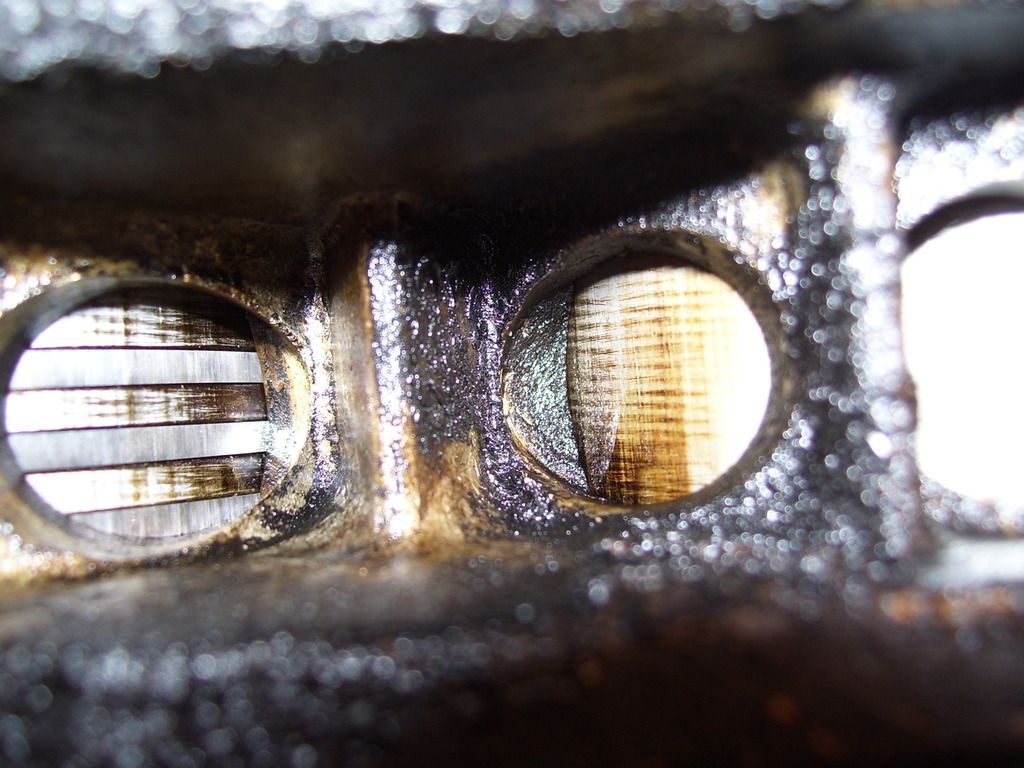

February 28, 2016 at 11:25 pm #32642Here are the best photos I can get after removing the exhaust cover. The pistons look lots better than the bore even though they are running at the worst part of the bore. Don’t appear badly scratched, not scored, rings push in and springback out easily. I don’t understand how the pistons appear ok – unless they have been replaced. There are some dings on the bearing races and the upper bearing race had a dimple where the bearing was misalligned with the oil connection and the crankcase was tightened (easily smoothed off.) So now sure that someone has been into the crankcase before me.

So I am left with two poor bores and good pistons/rings. I really like this old motor. I ran the motor a lot summer 2014. It did not start as well as it should and it did not always restart easily hot. The upper bearing leak got steadily worse and last summer the motor could not be used. When I took the motor apart this winter I found that the top bearing had an o-ring around it even though one was not supposed to be present.

Thrown into this is that I have the 54 Johnson 25 that has the same top seal leak and similar symptoms.

I can take advantage of Dan’s offer of assistance to bore and fit oversize pistons and rings or possibly someone closer to Maine has the experience. I’m also tempted to put it together and see what happens …

Anyone have any comments or ideas?

Thanks.March 1, 2016 at 2:34 am #32708quote Chris_P:There should not be an o ring on the top bearing for that model. Many times, one gets installed when they are opened up.I can see where this confusion comes from. By 1962 the o-ring on the top bearing was required, so anyone that had been trained to work on 60’s motors would likely have added that o-ring when opening up the older motors.

If you have 95 lbs compression and the scratches in the bore don’t feel to deep,you may want to run it as is, depending on how many hours it will see.

I have a 1955 Johnson that left the factory without a retaining clip on the bottom, of the bottom wrist pin. There was a groove cut half way through the cylinder sleeve, but the motor still ran, although poor idle have away the difference in the two cylinders.

-

AuthorPosts

- You must be logged in to reply to this topic.