Home › Forum › Ask A Member › ’60 Evinrude Sportwin 10 shifting problems

- This topic has 11 replies, 5 voices, and was last updated 3 years, 9 months ago by

labrador-guy.

labrador-guy.

-

AuthorPosts

-

March 24, 2022 at 4:48 pm #256782

Hello All, I have the above noted motor which has run very well for me for 5+ yrs. Last summer it started having shifting prob, ie: not engaging when put into reverse unless tried several times; then even not going into forward at times. I know to shift it with a ‘snap’, not to ‘ease’ it into gear. Are there any places I can adjust the shifting or am I looking at worn parts in the gearcase? The gear case oil looked OK, no sign of water or any significant crud when drained. I was hoping to avoid taking it apart. It does have the 2 piece shift rod with connector on the side of the lower unit. Thanks for any advice.

March 24, 2022 at 5:17 pm #256783check for looseness in the shift linkage. they tend to loosen under the powerhead.

grab the shift shaft then move the shift handle. should be NO LOOSE movement between them.

1 user thanked author for this post.

March 24, 2022 at 8:05 pm #256787There is some sloppy play there! I’ll take the powerhead off and check tomorrow. I was hoping to avoid breaking a good seal on the gearcase. Thanks! NABMD

March 24, 2022 at 8:20 pm #256788no need to open the lower unit! just pull the powerhead and retighten the linkage or whatever is loose.

March 24, 2022 at 8:46 pm #256789Did you check the bolt that holds the shift lever on. May be it moved a little. There is a small amount of adjustment. Move the lever back and forth. It could be moving to far one way. I check mine once and awhile and if I move the lever ajustment a little, it makes a big difference.

dale

March 25, 2022 at 12:21 pm #256816Thanks for suggestions. I won’t open the gearcase, and will check all the linkages and parts at the shift handle. I also saw the recent reference to fixing the shift handle opening (if excessively worn) with brass tubing and will do that if necessary. I’ll put in a new ‘O’ ring at the shift handle while I have it apart.

March 26, 2022 at 8:56 pm #256896Before pulling the powerhead, make sure the loose connection is not in the brass shift rod connector itself. These screws are often misinstalled/misaligned and stripped. The other possibility is that the find adjustment screw on the shift handle has come loose introducing slop between the shift handle and the horizontal shift shaft.

The problem is that running the engine like this may have caused damage to the clutch dog and gear lugs. But, you will never know until you address the slop in the system, readjust and try again. Good luck, hope it works out.

The only other thing that comes to mind is did someone accidentally/inadvertently remove the little phillips screw that is near the lower lube drain screw on the gearcase? If so, the internal shift linkage probably fell apart and you will probably have to remove the skeg in order to reinstall it properly. But again, if the engine has been run with this issue for any length of time, clutch dog and gear lug damage has probably occurred.

1 user thanked author for this post.

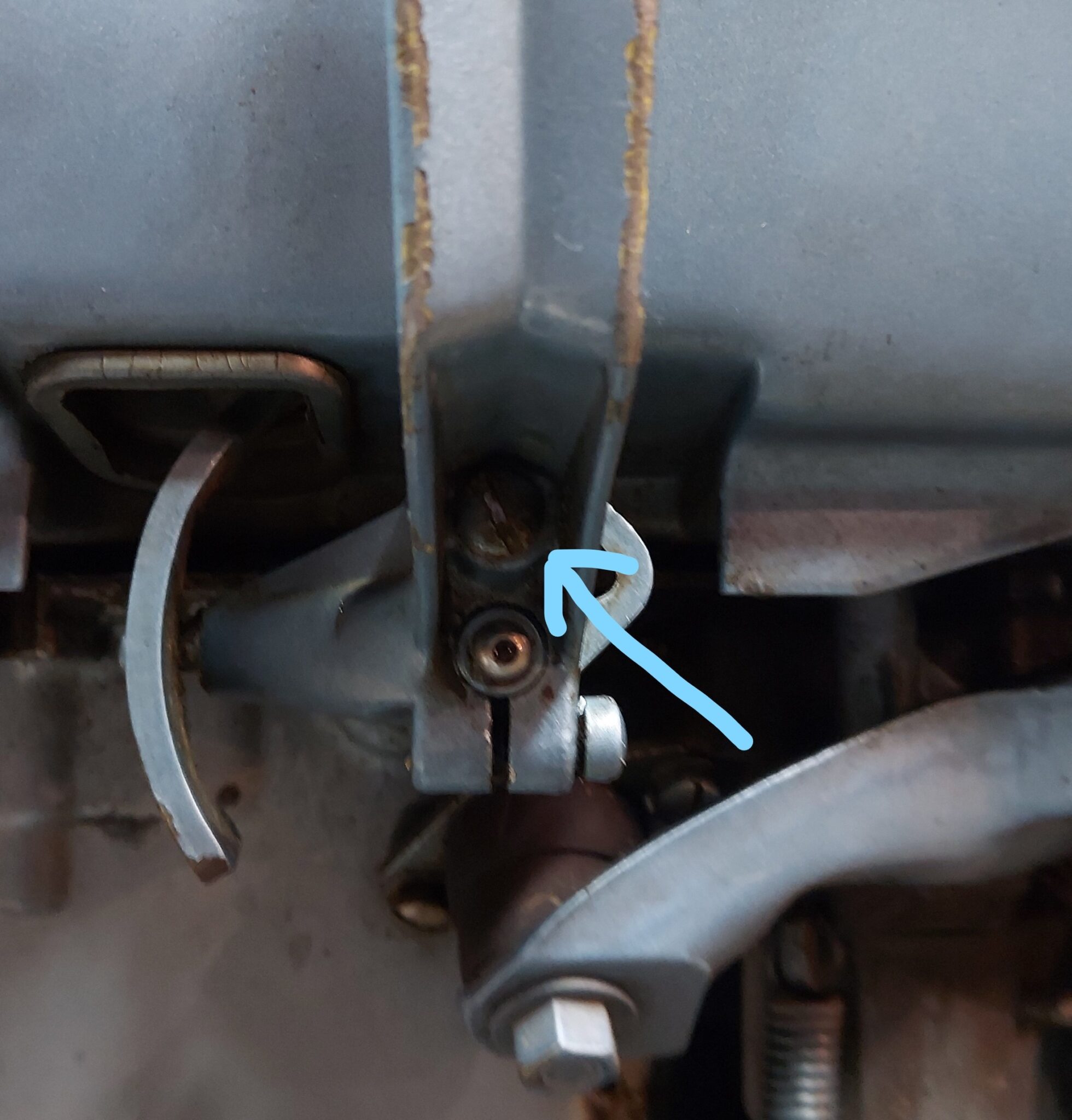

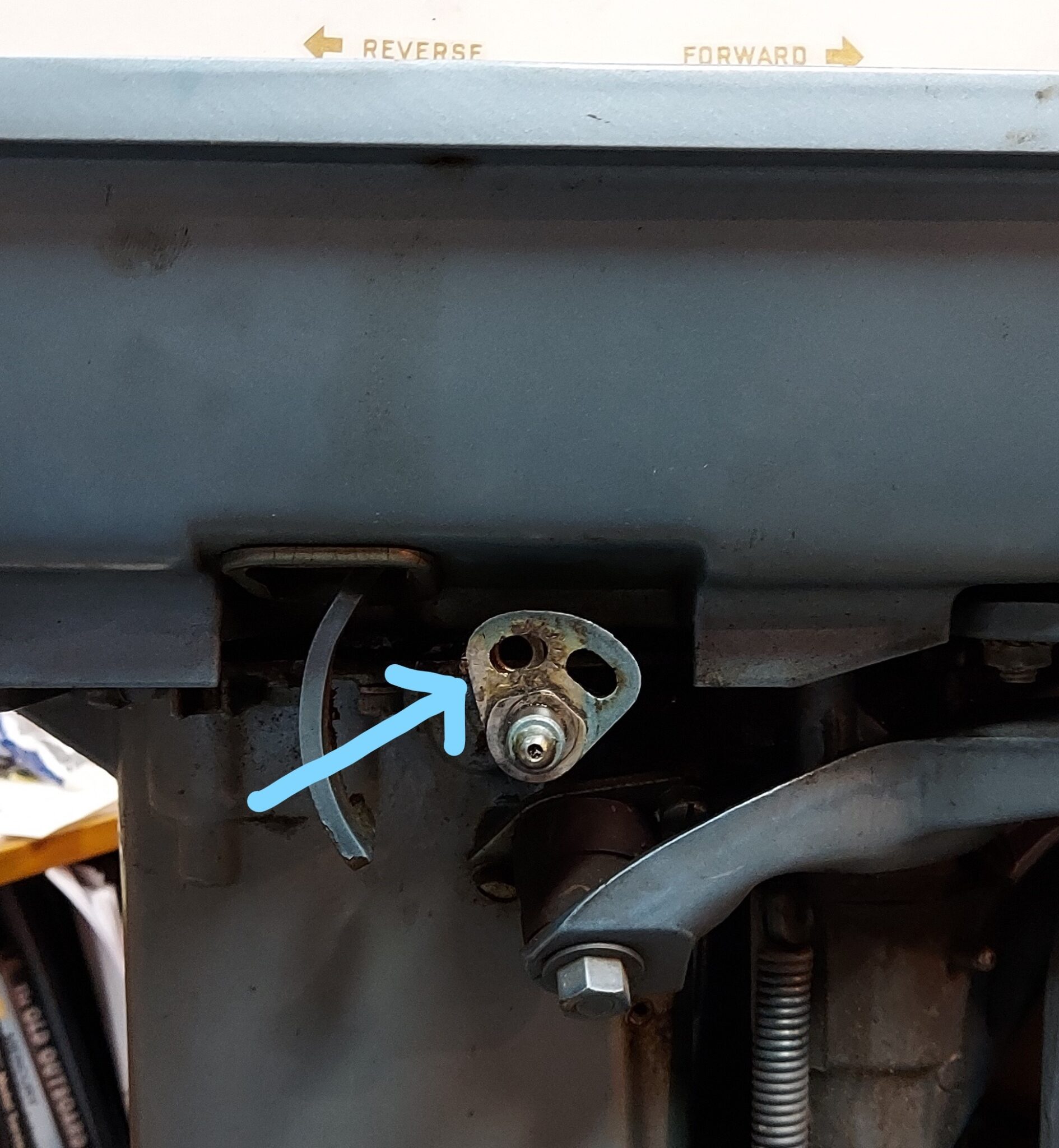

March 28, 2022 at 10:07 am #256968Update: Pulling the powerhead was a good idea, but was impossible for me with my basic tools. There are 5 screws that come up from below the lower cowling which were easy to get to and remove, but there are 3 nuts on the top side (sides and front) which are inaccessible unless you have a flexible head wrench. So I gave up on checking the internal linkage of the shift handle rod. The handle was slightly loose on the external end of the rod however. I found that there is an screw and bolt that tighten the handle to the rod. In my case, the nut on the back side was completely off the screw and just stuck in old grease! There is an oblong opening on a small plate on the rod which allows adjustment of the handle with regard to the rod. See attached pictures.

There is also a second screw that compresses around the rod that was slightly loose. The connector of the 2 part shift rod in the middle of the lower unit was tight. I’ll have to try it once the test barrel won’t freeze and make adjustments as necessary. Thanks for all the advice. NABMD

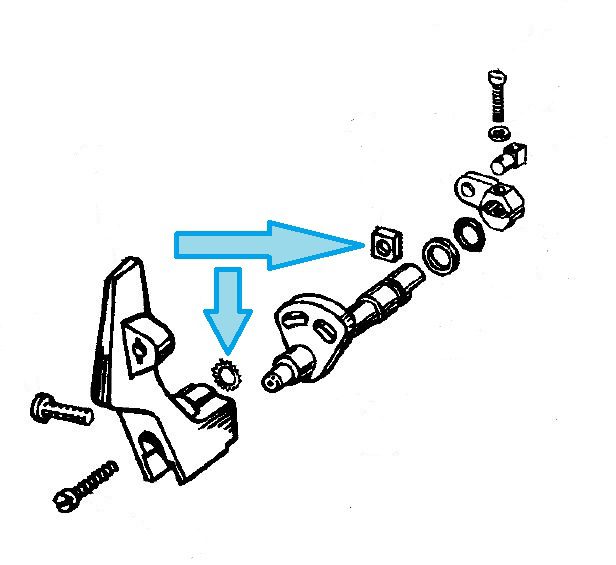

March 28, 2022 at 6:00 pm #257056The nut which was laying in the grease should be a square nut as used on stove bolts. A square nut will get captured and a wrench wont be necessary on it when making the adjustments. Don’t forget the star lock washer which goes between the shift lever and the flange on the shift shaft. All threads on the adjusting hardware are 1/4 X 20 thread.

March 29, 2022 at 10:09 am #257105That is exactly how it was, just the nut was not on the screw; and I put it back together the same way. Thanks

-

AuthorPosts

- You must be logged in to reply to this topic.