Home › Forum › Ask A Member › 6039 Speeditwin Flywheel torque

- This topic has 23 replies, 5 voices, and was last updated 6 years, 1 month ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

December 31, 2019 at 5:53 pm #190351

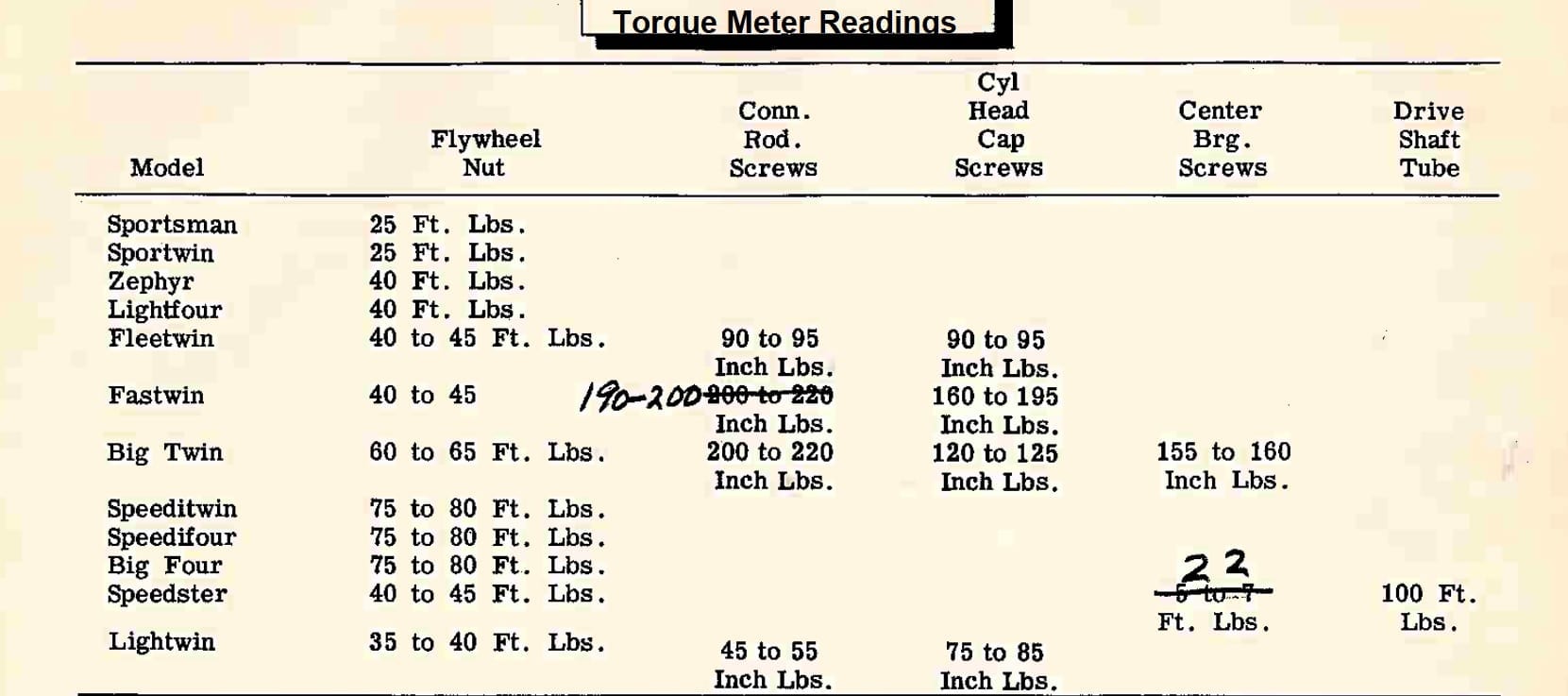

I’m not finding any flywheel torque specs for the Speeditwin.

Is there an official torque for these?The flywheel, crankshaft keyway and key were totally messed

up on this unit when I got it. I don’t want the same to happen

to my replacement flywheel.For starters, I torqued it down to 60 ft pounds (after I confirmed

nice spark).Being the flywheel nut is a two sided flat, I’m doubting if anyone

ever put a torque wrench on these Speeditwins.Did Evinrude have a special socket for these nuts?

I had to improvise to use my torque wrench, using a 1/2″ to 3/4″

drive adapter, flat iron, and two C clamps. Crude, but it worked fine.Prepare to be boarded!

December 31, 2019 at 6:20 pm #190358I was told 60 ft lbs was correct .. I pick up a crowfoot socket 1/2” drive at IIRC Advanced Auto parts … 3/4” I think …

December 31, 2019 at 9:01 pm #190367Thanks for the reply. Does using a crow foot wrench on the torque wrench change the accuracy

of the torque wrench reading?Prepare to be boarded!

December 31, 2019 at 9:21 pm #190369If you set the crows foot wrench in a straight line with the torque wrench head then yes, it will result in a higher torque setting than what you want. The crows foot should be set 90 degrees to the torque wrench head. Here’s a video that explains it.

https://www.youtube.com/watch?v=fBjr9-FDWYw

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."December 31, 2019 at 9:25 pm #190370That’s a good question …

And I don’t have an informed answer ….

I don’t really think it would decrease the torque a lot . The 1/2” drive hole on the socket is fairly close

to the open end of the wrench center …December 31, 2019 at 9:38 pm #190372Interesting video … I picked up one of these to use .. I wonder how accurate it is ..

https://www.harborfreight.com/12-in-drive-digital-torque-adapter-63917.htmlJanuary 1, 2020 at 8:50 am #190384I believe that the Speeditwin owners manual says “hammer on wrench”

I take that as pretty darn tight.

Leads me to believe that OMC wasn’t concerned with an accurate torque, as long as it was tight.I believe that the threads are 5/8-18. They would probably be good for 100 ft lbs plus, as threads go.

I personally use a modified strap wrench on the flywheel to hold it still and a 3/4 wrench in the other hand, and pull it tight and then some.

A loose flywheel on an opposed twin will scrap your motor quickly.

Mark

January 1, 2020 at 10:03 am #190386January 1, 2020 at 7:33 pm #190454disappeared post

January 1, 2020 at 7:44 pm #190460

January 1, 2020 at 7:44 pm #190460eighth thy –

-

AuthorPosts

- You must be logged in to reply to this topic.