Home › Forum › Ask A Member › ’60s Johnson water pump – Freeze Damage

- This topic has 13 replies, 9 voices, and was last updated 10 years, 2 months ago by

mas.

-

AuthorPosts

-

December 12, 2015 at 8:57 pm #3162

I am a bit taken aback with what I found in a mid ’60s Sea Horse 33.

We don’t see much freeze damage here in Florida, so, this type of damage is new to me.

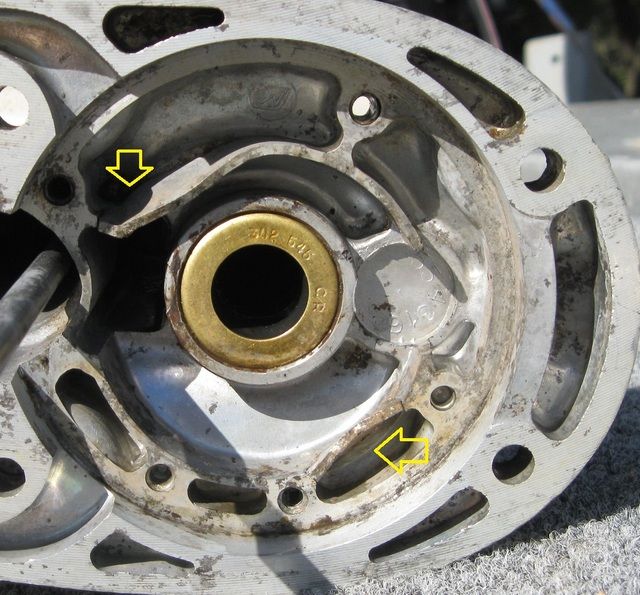

This issue is beneath the stainless impeller plate of the water pump on the lower section.

As you can see, one chip is completely broken out and on the other side, there is

some deformed and cracked metal.

Is it safe to just clean it all up, make sure it is flat with the rest of the base and run it

as is ? or, start looking for another foot or case.

December 13, 2015 at 2:54 am #28521

December 13, 2015 at 2:54 am #28521Try grinding it out a bit and using epoxy in there. It’s not a load bearing area so should be just fine.

The area with the piece that came free I think I would again use epoxy without grinding and press the piece in place until dry. After that do your grinding and add an epoxy filler.

Kinda’ looks like that engine came from Minnesota….December 13, 2015 at 3:07 am #28523Thanks Pap, that was my "Plan B" – – – straighten it all out and fill the voids with

epoxy putty, lap it all down flat n flush and on to the next step.

I just wanted to make sure that the voids were not designed for some specific reason

like for water flow, cooling or siphoning, etc etc etc.

All in all, it will be a jam up motor. New water pump, impeller and shaft seal and will be able to

crank it over. The carb is soaking in parts cleaner. It is very clean on the inside.

Thankssssssssssssand I would suggest if you live in Minnesota or North Dakota, get all the water out prior to winter storage.

December 13, 2015 at 5:13 am #28528I don’t think the open area would bother the water flow enough to do anything. With a good impeller you would still get plenty of water. If it was a racing motor?

Talking about possible freeze damage, My grandmother lived in G-ville, Fla. – 180 miles north of me in Venice. So we always went up for holidays, and I would give her classic Buick a look over. Every year, for some reason her radiator water would be nothing but rust, even though I flushed it and put in fresh anti-freeze every year. Sometimes it would be below freezing, I basically KNOW her "mechanic" was dumping my anti-freeze and filling it with straight water, hoping for a busted radiator or, even better for them, the block! I know, it’s Florida, but temps in the teens for days will break a block full of water, won’t it? And yes, it will get that cold in north Fla.December 13, 2015 at 1:32 pm #28533oh yes, Florida does have its cold weather !! (sometimes).

Not like up in the Great White Nawth, but enough to put on the mittens, LOL.

And speaking of cold, Central Florida is normal – – – high ’80s two weeks from Christmas !!!!I will get some of that Tuff Poxy at NAPA tomorrow. I know those little sides are not

structural. More like keeping the impeller cool and to save aluminum in the manufacturing process.

I will post pics after it’s done. Basically, brace the outside of the thin wall, fill the inside

with epoxy putty, then finger out the middle to restore the air pocket, sand it all flush and reassemble

with a few new parts.Johnny –

Florida Native and Central Florida Resident since 1948December 13, 2015 at 3:40 pm #28536Just get a good clean roughed up substrate to help the epoxy bond. No corrosion on the surface or the epoxy will not bond for long.

December 13, 2015 at 6:41 pm #28546A good reminder to be sure to get all the water out and keep the drain holes clear. I thought of also dipping my lower units in 50/50 antifreeze water or RV antifreeze for a minute or so to displace and dilute any water. Maybe turn it over without starting to get the antifreeze up into water pump. What you guys think?

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonDecember 13, 2015 at 7:21 pm #28549My bet is that it may have come from some previous owner prying out the driveshaft seal. That part cannot take much load if you try to pry against it with a seal puller or screw driver.

Then again freezing is also a good theory. Good luck

Allen

December 13, 2015 at 8:55 pm #28553Never seen anything like that and I do live where it freezes. Raglover appears to be correct.

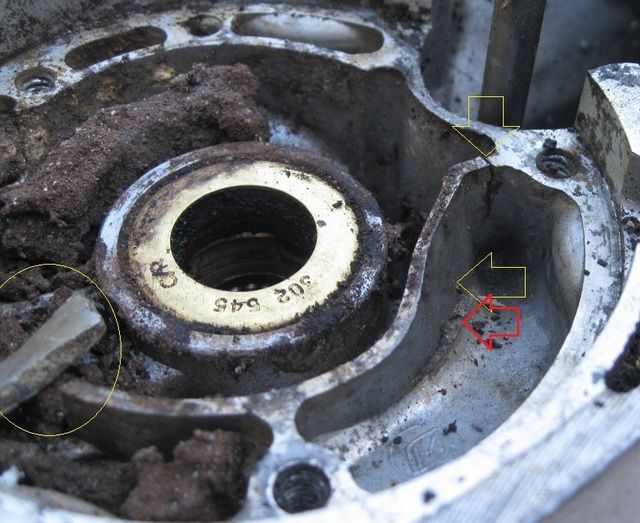

December 13, 2015 at 9:36 pm #28555upon reading the responses, I went back for a closer look on the top edges and there are no

obvious tool pry marks that would exert that much force. Also, the photos show

that the expanding force came from within the cavity, pushing outwards. I found a crack

in the bottom of the cavity on the right (red arrow) that I did not notice before – and it is definitely pushed out by force.

With that evidence, I am pretty sure it is from freezing. And that Mississippi Mud probably didn’t help much either.

with a little finese and poxy putty, it will be as good as new in a couple of days.

Thanks to one and all for the feedback..

-

AuthorPosts

- You must be logged in to reply to this topic.