Home › Forum › Ask A Member › Ball tooth cog broken- fix???

- This topic has 4 replies, 5 voices, and was last updated 6 years, 4 months ago by

olcah.

olcah.

-

AuthorPosts

-

October 29, 2019 at 8:39 pm #186119

I have a ball tooth cog/shaft from a tiller handle that has a broken tooth.

I also have this ball tooth cog without a shaft lying around.

The holes for the roll pin to go into are in different positions from each other.

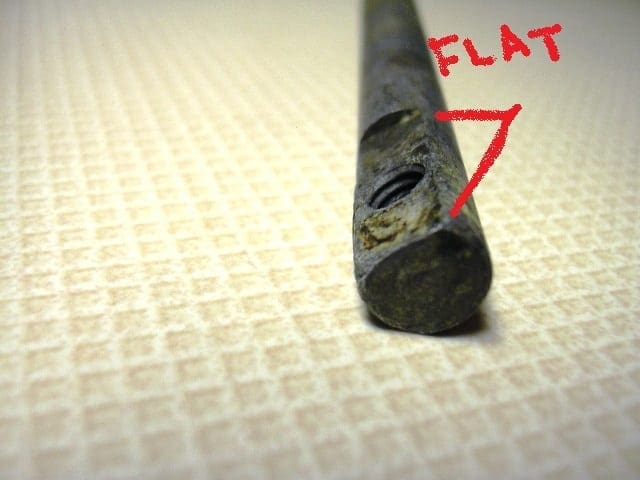

Does it matter? I’m thinking yes because of the flat spot on the end of the shaft.

Can some dentist enlighten me?

Also

Are pointy tooth cogs and ball tooth cogs interchangeable?? or once again the flat spot on the shaft is a critical factor?October 29, 2019 at 9:16 pm #186130No, the pointy ones and cast ones are not compatible. The reason the pins are in different locations is because the shaft and gear was first put together in their correct relationship, THEN the hole was drilled through both parts at the same time. You can do the same thing, put them together, then drill a new hole through both in a new location.

October 30, 2019 at 9:55 am #186142Check the P/N’s for the shafts as I’ve come across different shafts for different years of the same model motor. This just happened with some six horse motors I have. I can’t remember the exact years but using one shaft from another motor would have worked but the speed indicator on the grip would have been totally wrong. It seems the gear is clocked to the shafts flat spot for the grip before being drilled. And yes, the broken ball on your shaft can be repaired by tigging it up and filing it back to shape.

October 30, 2019 at 10:55 am #186151Reminds me of OMC I/O drives with the same tooth pattern to engage the outdrive. Both of mine were worn 1/2 the way through from running tilted up & never greased.

November 1, 2019 at 7:18 pm #186299I had a shaft with good teeth from another model. As your photo shows the toothed part is held to the shaft with a pin. I removed the tooth part and made another hole in the toothed part for a new pin at the same orientation with respect to the shaft flat as the broken one. As I recall I made the new steel pin on a lathe, put things together and staked the ends of the pin. That fixed it.

-

This reply was modified 6 years, 4 months ago by

olcah.

olcah.

-

This reply was modified 6 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.