Home › Forum › Ask A Member › Big Twin Correct Starter Identification

- This topic has 34 replies, 9 voices, and was last updated 5 years, 8 months ago by

olcah.

olcah.

-

AuthorPosts

-

February 20, 2019 at 9:25 pm #167723

I had an interesting experience this week that confirmed what Frank said above.

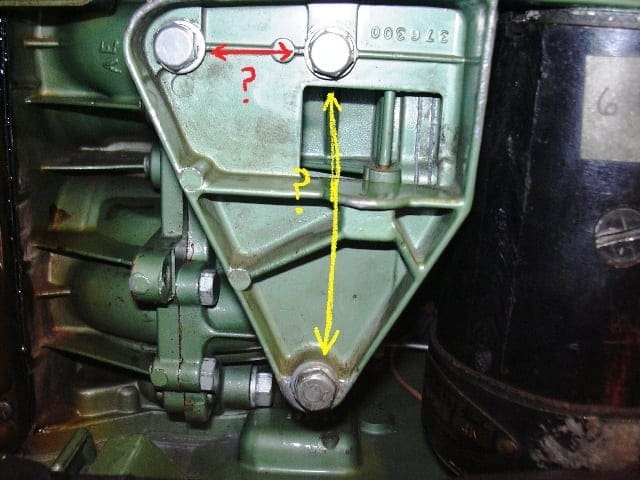

I wanted to order a new starter for my 1956 Johnson 30 HP RDE18. Originally the 1956 RDE18 came with a 6V starter. The old starter is Autolite MDH4001M. Distance between the mounting screws on the starter is 2 1/4 inch center to center. I have 3 of the matching bronze colored brackets. They match the 2 1/4 inch bolt spacing. I looked on Ebay at Total Power Parts and called them about their item 5270. According to their info on Ebay that is replacement for the MDH4001 starter. The person who assisted me checked their own screen data and it appeared to say that the bolt spacing was 2 1/4 inch.

Received the starter yesterday. You guessed it. The spacing on the starter was close to 2 1/2 inch. I also have one other bracket. It is painted white, It was on an RDE18 and had a bad starter . Stamped onto that starter is Autolite MDO4002M 12V. I put the new starter on the white bracket and the starter engages the flywheel and spins the motor over just fine.

The starter was $55 and is from Taiwan. No other identification. Because of fumble fingers I wound up removing the end cap. The inside looks like decent quality construction, nice commutator and good setup for brushes which look easy to replace.

The white bracket has two sets of starter mounting holes, the tapped ones about 2 1/2 inches apart and two others not tapped that look to be 2 1/4 inch apart.

So I think 6V starters have mounting screws 2 1/4 inch apart and are labelled MDH4001. 12V starters have mounting screws about 2 1/2 inch apart and are MDH4002 and are labelled with 12V. I think the white bracket was originally from a 1957 or 1958 35 HP as it has a shroud pin.

I still wish I could get a starter 6V or 12V with 2 1/4 inch spacing to use in the bronze colored brackets. Does anyone know a source?

-

This reply was modified 7 years ago by

olcah.

olcah.

February 20, 2019 at 9:44 pm #167735Anonymous

If you have a defective or non operating starter that fits, why not just repair the starter? Its sounds like that would be the easier route to go. Most parts are available to do repairs and I have done many for Johnson, Evinrude, and Mercury starter motors.

February 20, 2019 at 10:04 pm #1677443 words: LIFE IS SHORT. Starters are cheap, time isnt. I want to push a button and run the motor. Not have to spend my few short months of warm weather this summer holding my breath hoping to not deal with a hastle.

Motor is for a customer with deep pockets. If it doesnt work 100% of the time for the next 10 years, it’s gonna be a drama situation for yours truly.

February 20, 2019 at 10:48 pm #167755Anonymous

A couple of the common things that cause the starter to give up, are the lead from the field winding to the positive cable post breaks off the post because the post is loose caused by tightening and loosening the cable mounting nut. The other is worn out brushes. Even a new starter can have these two problems that are caused by the installer and the operator through no fault of the starter quality. The quality of new non USA or rebuilt outside of the USA starters leave a lot to be desired. I would trust a old original equipment starter that was rebuilt by a shop in the USA than either of the other two sources. I get a lot of work from the new or built starters from over seas that fail right away or give up after a short time. No starter is going to last 10 years with out servicing. Greases get hard, brushes wear out and the dust from the worn out brushes can stick the brushes and cause the starter to drag burning out the windings. Dry bushings wear and cause drag over heating the brush springs and so many more. They all will need servicing. If your customer expects to go ten years with no starter problems, put the outboard on a preventive maintenance schedule that includes removing the starter for servicing, disassembly and cleaning and lubricating and brush replacement before a break down.

February 21, 2019 at 6:46 am #167764So there you have it. 6V = 2 1/4″ apart and 12V = 2 1/2″. I’ll make a note of that. Then try to remember where I put the note.

February 21, 2019 at 8:43 am #167767So there you have it. 6V = 2 1/4″ apart and 12V = 2 1/2″. I’ll make a note of that. Then try to remember where I put the note.

Thanks Frank. Information filed.

C://Outboards/System Repair/Electrical/Starters

🙂Prepare to be boarded!

February 21, 2019 at 9:09 am #167768In interest of accuracy the 12V is actually just under 2 1/2 inch apart. Actual dimension is about 2 7/16 (2.430 inch) centerline to centerline of bolts.

February 21, 2019 at 11:04 am #167778February 21, 2019 at 11:07 am #167782We are talking about the spacing where the starter thru-bolts thread into the bracket. At least I believe we are.

February 21, 2019 at 11:27 am #167787Is there an easy way to tell the difference between a 1950’s Johnson 6 volt starter bracket and a 1950’s Johnson 12 volt starter bracket????

I find the easiest way is just by looking at them. All of the six volt starters I’ve ever seen have an inspection band on them over the brushes at the bottom of the housing. The twelve volters don’t.

That’s just my observation so your mileage may vary.

EDIT: I guess I should clean my specs. It was the BRACKETS you were asking about, not the starters.

-

This reply was modified 7 years ago by

Mumbles.

Mumbles.

-

This reply was modified 7 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.