Home › Forum › Ask A Member › CD-19 Shock absorber?

- This topic has 21 replies, 8 voices, and was last updated 8 years, 4 months ago by

bullie.

bullie.

-

AuthorPosts

-

August 19, 2017 at 7:58 pm #63474

I nudged it down around a little over a 16th, put the water pump back together, then gave it a little spin with the drill. Water is pumping fine.

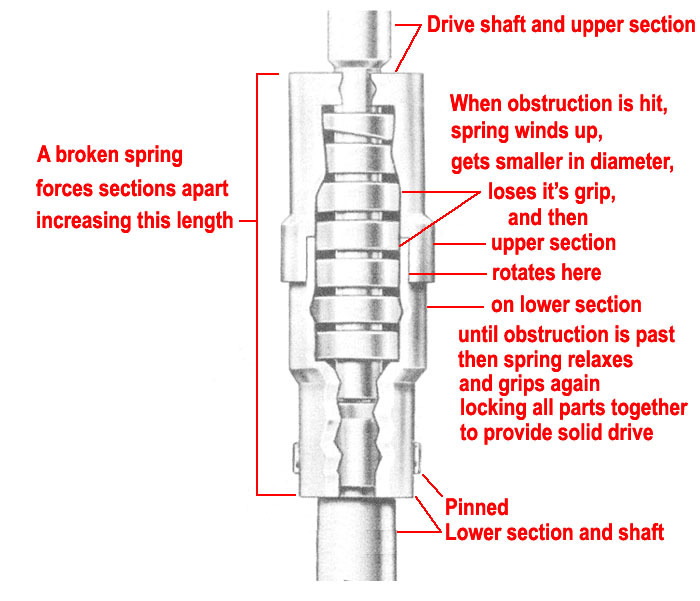

August 19, 2017 at 11:27 pm #63479In my opinion, if one of these shock absorbers has ever been sprung and endedd up too long, after you press it back to the correct size WELD that thing together and use a brass pin. They will expand again and start dragging again the first time they bump something, or before you even hit anything.

-BenOldJohnnyRude on YouTube

August 29, 2017 at 1:53 am #63979Update. New base gasket came in today so I put her back together. It may be the best runner I have. I almost have to choke it to kill it. It will idle down to almost nothing.

The bad (kinda) part: It still wasn’t spewing any water. I took its temperature and the hottest spot I could find was about 125 so I figured it was pumping water well enough. I ran a wire up the exhaust relief and got a little trickle of water. Kept at it and it is spitting a good bit now. Still not what I think it should but it might get better the more it runs.

I am really liking this one. It is super clean and looks new under the cowl. Might be a keeper. But, 1962 is a bit too young.

August 29, 2017 at 6:54 pm #64003quote Fisherman6:In my opinion, if one of these shock absorbers has ever been sprung and endedd up too long, after you press it back to the correct size WELD that thing together and use a brass pin. They will expand again and start dragging again the first time they bump something, or before you even hit anything.

-BenI was going to say this too, but it sounds like he has it back together already :-0

August 29, 2017 at 8:18 pm #64006The bearing surface on the underside of the water pump base will be worn if the shock absorber is shot.

August 29, 2017 at 8:37 pm #64010Y’all ever done anything fast and got all happy with the results then someone tells you that your happy is gonna be over about as fast as it arrived?

August 29, 2017 at 10:22 pm #64016Definitely too long. That puts an extra loaded on the engine and makes them run hotter. I have seen them push that bushing into the water pump. If it isn’t broken, it may take an arbor press to push it back together. . . 😉

August 31, 2017 at 2:29 pm #64088

August 31, 2017 at 2:29 pm #64088There is a thread about this here: viewtopic.php?f=2&t=8276&start=20. And there are others. I would use a tube and press the two sections of the shock absorber housing together until they bottom, which should give you about 6 11/16 as stated above. There should be a little end play as assembled in the leg. There is potential for the housing parts to separate again, of course. Mine hasn’t, but I haven’t hit anything either. I suggest keeping an eye on freedom of rotation. If it seems to tighten up again, you could consider welding or pinning the housing halves together.

August 31, 2017 at 2:37 pm #64090If you do compress and the weld it together, be sure to use a brass shear pin to protect the motor from impact. . . 🙂

September 1, 2017 at 2:03 pm #64127

September 1, 2017 at 2:03 pm #64127Thanks for the link and the advice guys. I appreciate it. After checking out the the link from amuller and then doing a web search, I think I have decided to run it for a bit. If it lengthens out again I will weld it and make a brass shear pin for it like I was advised. Or, maybe I can use another shock absorber from a later model LU. I have a couple from the mid 60s I think. Would they fit?

-

AuthorPosts

- You must be logged in to reply to this topic.