Home › Forum › Ask A Member › CD12 strange cooling issue

- This topic has 43 replies, 12 voices, and was last updated 6 months, 4 weeks ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

June 28, 2025 at 9:42 am #297644

String trimmer line may work also.

June 28, 2025 at 10:04 am #297651Thanks all for your helpful suggestions!

I took the power head off again (getting good at that now 😉) and sprayed water through both the incoming and outgoing port of the power head. Enough water came out to rule out a blockage.

Until now I only focused on the impeller side of the lower unit, so to be sure I also checked the exhaust part. Again, no issue found.

So to summarize, everything seems to work as it should, until I bolt on the power head. Then I have a few seconds of water until the water flow stops and powerhead starts heating up.

My money still is on the gasket, although I’ve checked it multiple times now and cannot find anything that stands out.Tomorrow I will try to poke the holes with some trimming wire, but I have low hope for that.

June 28, 2025 at 10:51 am #297657Don’t despair…… years ago my Merc 45 classic drove me nuts …

the inflow of water to the impeller pump was being blocked by a ” floating grommet” found BELOW the impeller housing in the LU cavity. ! How it got the remained a mystery till I sold it 🙁 Fantastic engines those 4 cyl Mercs )

Joining AOMCI has priviledges 🙂

June 28, 2025 at 12:32 pm #297687I’ve been reading all this with interest and sympathy! I’ve been there as well….mostly with Mercury.

One thing that it doesn’t appear that you’ve done is to hook up a water source (garden hose) to the copper tube; gearcase removed and powerhead installed with the proper gasket. Turn on a gentle flow and observe what happens. If you get consistent flow….it would point to some sort of issue with the impeller housing….maybe something like Crosbyman found .

June 28, 2025 at 3:47 pm #297713Strangely the drill test (see pic) directly on the drive shaft at the top of the lower section shows tons of water shooting out and should flood the engine’s water cavities… cyl jackets and all. A section of SS steel cable (small & flexible ) on a drill should work it’s way around the engine’s water cavity and hopefully exit somewhere clearing out any debris.

the amount of water gushing out on the drill tests should eliminate any possibility of obstructions below the impeller housing. should….

hopefully the PH is the original CD12 PH and matches the base gasket pattern ….OMG !

up the creek nothing works…? pulling welsh /frost plugs may provide ” insight” to cavity blockages..

Joining AOMCI has priviledges 🙂

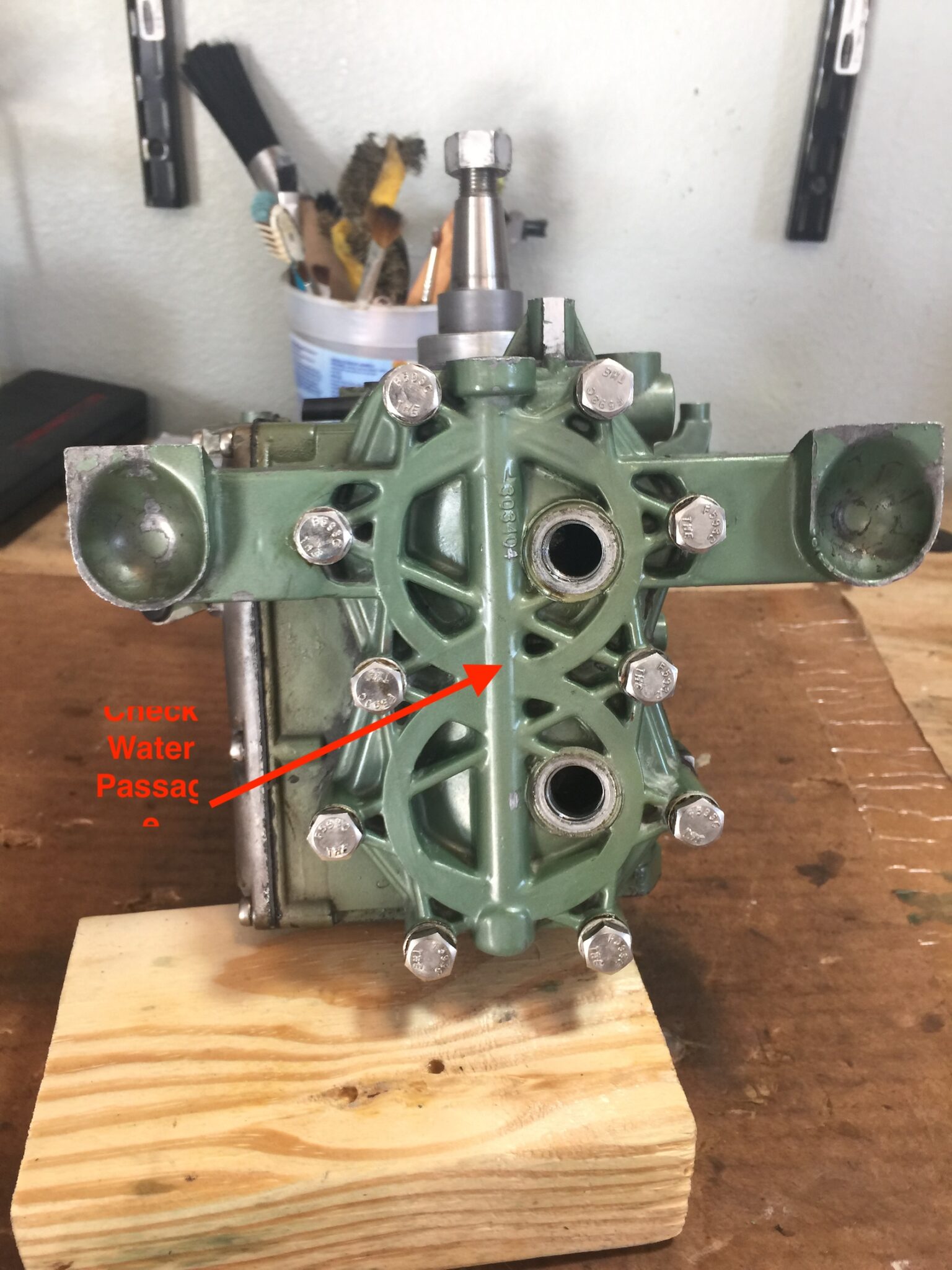

June 28, 2025 at 9:52 pm #297726If you haven’t done so already, pull the cylinder head and check the vertical water passage at the back of the head. When I rebuilt my CD-11 I found this passage partially blocked with trash/debris. I’ve had a couple other motors where this passage was also clogged, on one motor it was totally blocked with leafy, weedy material. See pic.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."June 29, 2025 at 5:15 pm #297758Joined just now as well….

Looks like the pump is working pretty well from the drill test. But, there is no exhaust going through down there when you are pumping with the drill. So, there is the possibility of some sort of air leak under the pump, pulling exhaust is a whole lot easier than pulling water. I am also assuming the gearcase is buried deep in the water (over the gearcase/ex hsg joint) while running the engine in the bucket.

Was this engine new to you? Did it ever pump water correctly? If so, what changed since that time…. The wrong base gasket will defiinitely cause a water leak and possible overheat. Are you sure the surfaces of the exhaust hsg and powerhead are in good shape, not corroded/damaged?

The water may be getting to the powerhead OK, but may not be able to circulate through or exit the powerhead.

Like others have suggested, you might want to install the powerhead/base gasket without installing the gearcase. Now connect a small rubber hose to the copper water tube and adapt it to a garden hose. Now turn the garden hose on just slightly to see if water circulates through the powerhead and exits from the exhaust relief…. If not, then there is some sort or restriction in the powerhead.

I know that on the 5.5/6hp models with the thermostat, water exits the block through a pesky right angle passage on the right side of the block on the bottom, this gets plugged relatively easily…

June 30, 2025 at 2:12 am #297764The engine is new to me and didn’t run when I got it about a year ago. The previous owner bought it with the intention to restore it but the price tags on the included spray paint dated back to 2014. My guess is that it hasn’t run for much longer.

I’ll be gone this week and was hoping to take that motor with me to test it. Looks like I’ll have to bring another one then.

I have a new base gasket ordered but it will take at least another 3 weeks to arrive, when I get back next week I’ll attach a garden hose to the water tube and see what that tells me. I’ll report back to let you know how it turned out!June 30, 2025 at 7:52 am #297765The engine is new to me and didn’t run when I got it about a year ago. The previous owner bought it with the intention to restore it but the price tags on the included spray paint dated back to 2014. My guess is that it hasn’t run for much longer.

I’ll be gone this week and was hoping to take that motor with me to test it. Looks like I’ll have to bring another one then.

I have a new base gasket ordered but it will take at least another 3 weeks to arrive, when I get back next week I’ll attach a garden hose to the water tube and see what that tells me. I’ll report back to let you know how it turned out!Cool! Coat the base gasket with grease so it doesn’t get ruined for the test. You could also start the engine while attached to a garden hose. Sometimes, a blown head gasket will create enough back pressure into the cooling system to stop/hinder water flow as well.

July 1, 2025 at 5:58 am #297793Remove back exhaust stack cover with the three screws and check for blockage from wood wasps.

-

AuthorPosts

- You must be logged in to reply to this topic.