Home › Forum › Ask A Member › Force120 miss cyl. New development

- This topic has 18 replies, 5 voices, and was last updated 1 year, 4 months ago by

Beno.

Beno.

-

AuthorPosts

-

June 28, 2024 at 1:26 pm #288702

Working on this engine. re-did the compression test. here are my numbers

123/150+/150+/150+

What do I do? I re-checked it a few times. In the past I kind of always thought that anything over 120 has gotta be a good cyl… now I’m re-thinking that.

Is this bad enough to justify that the head is leaking?

Tear down the head?, sand, plane and reattach? gonna be a 4 hour job no matter how I cut it.

I have a leak down tester at my friends house. should I do a leak down test first?

June 28, 2024 at 2:05 pm #288708Easiest thing first. Not familiar with that engine but does it have intake bypass covers on the side of the powerhead If so, remove the one on the low cylinder and take a peek inside for possible damage such as a busted ring.

June 28, 2024 at 2:31 pm #288711good idea.. also I’ll get the bore scope going, it’s the top cyl.. so It may be easier. that way.

along with the leak down test at BDC

June 28, 2024 at 7:32 pm #288721Ok heres the Lower Reed Set..

June 28, 2024 at 7:34 pm #288726Here is the Upper Set…

June 28, 2024 at 7:35 pm #288731and yes. the cyl with the low compression happens to match the cyl with the chipped reed.

July 5, 2024 at 5:38 pm #288872Ok pulled the head. here’s the inside:

you can see the one black Cyl1.. I’m guessing its black because of unburned oil and carbon and water combining? or just misfiring

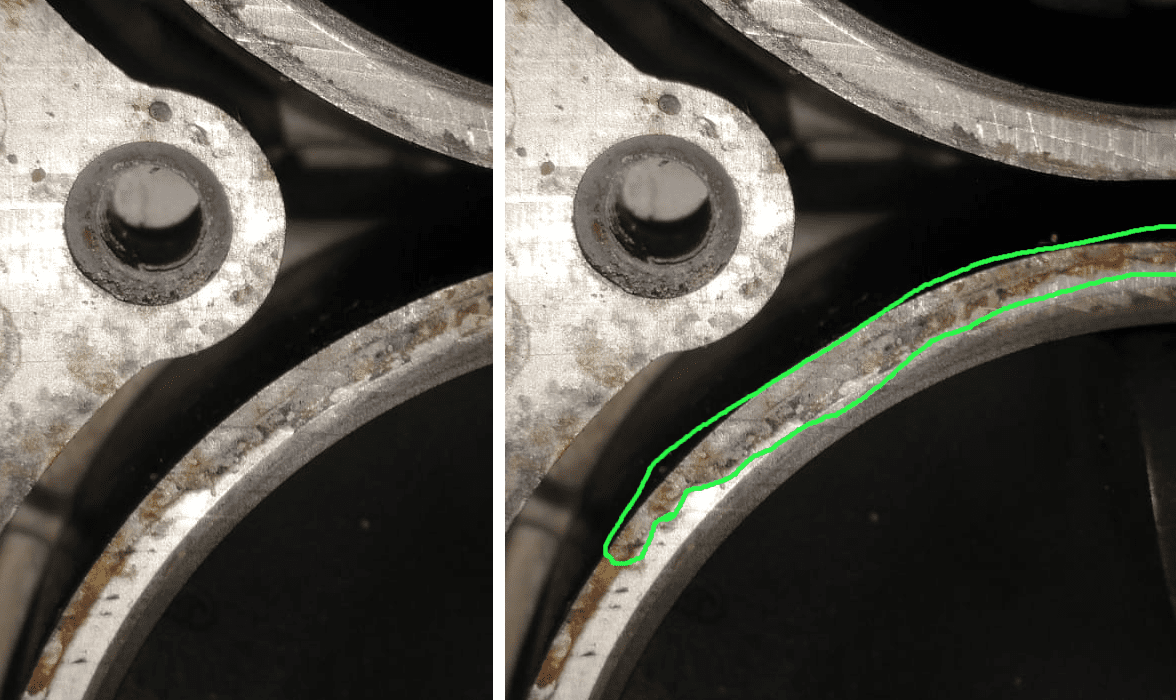

it’s REALLY hard to see but here is what looks to be Failed head gasket location.. This doesn’t have a actual broken gasket (hence why compression stayed above 123psi?)

this is a tough debug… but you see how the metal contact part of the head gets shiny and polished.. it’s vibrating there and not firmly Connected to the gasket at that point.. each power and exhaust stroke it’s expanding and contracting.

it will never burn thru because on every stroke it’s getting some fresh cooling water past it..July 5, 2024 at 8:40 pm #288882July 11, 2024 at 6:05 pm #289069I’m waiting on the arrival of the new head gasket.

does anyone know what the best “scuffing” methodology approach is for the block side of the preparation, I’m using decent sandpaper about 150 grit or so.

should it be scuffed all in one direction?

or circular using the piston center as the basis?

or some sort of random?

or scuffed in arrays.. like spokes of a wagon wheel?

see pics of the block attached.July 12, 2024 at 6:52 am #289081it is called cross-hatching for a reason…

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.