Home › Forum › Ask A Member › Cooling on ’55 3hp lightwin

- This topic has 6 replies, 5 voices, and was last updated 4 years, 7 months ago by

psquared lightwin3.

-

AuthorPosts

-

June 17, 2021 at 5:30 pm #240478

I’m reviving this ’55 3hp lightwin that has been sitting around for many years. It’s SN3014 12506. I replaced the cooling pump impeller and wear plate. I have been able to get it running, but I don’t want to let it run very long because I don’t see water squirting out of the back. I am concerned that the water isn’t really circulating, so I haven’t let it run for all that long. Isn’t water supposed to be squirting out from this motor as a witness to cooling water circulation? What’s my next move? Any advice would be very much appreciated.

When I replaced the impeller, it seemed like everything went together okay. There something resembling a piece of hose in the top of the pump housing and there is this tube that heads up towards the power head that inserted into that hose. The hardest part was getting the shaft to fully insert into the lower unit, but I finally got it to go in by getting the parts down inside of it all lined up.

June 17, 2021 at 7:44 pm #240494It should spray droplets of water out those holes, blown out by exhaust.

June 18, 2021 at 8:22 am #240514Seems like you had a tough time lining up the water tube and crank splines…I am assuming you are referring to the rubber water tube grommet on the top of the impeller housing. Is it possible that you had the water tube misaligned during assembly, it may have gotten jammed and pushed upwards/bent….

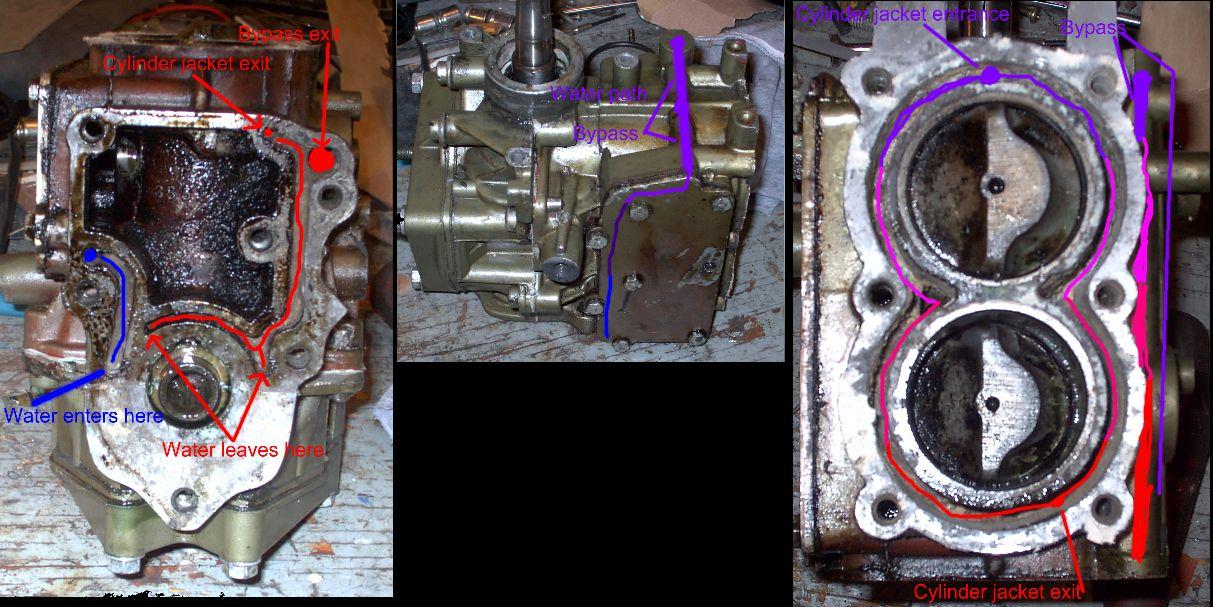

I would pull the gearcase back off if you don’t even feel a misty spray out of those little exhaust relief holes behind the exhaust housing. Once the gearcase is back off, please be sure you lube the driveshaft splines with moly lube and that the oring is in good shape…June 18, 2021 at 10:28 am #240524In my salt-water area I sometimes see Lightwins with water passages completely blocked with corrosion. The only solution i to pull the powerhead….remove the cylinder head and exhaust cover and locate and clear all the passages. It’s easy enough assuming things come apart without breaking bolts.

Most likely this will not be necessary on your engine but I have attached a picture of the passages. I wish I knew who to credit this picture; I have had it for years after downloading it from one of the forums.

Good luck; don’t run it until you are confident that it is cooling adequately.

June 18, 2021 at 10:34 am #240527No sense looking for spent cooling water coming out of the back. The only water that comes out of that model, is from the exhaust relief in the front of the lower unit.

The water will be mixed with exhaust, and comes out as a sputtering spray. If you cup your hand at the relief holes, it should fill with water. This may be easier to observe than looking for spray.

This model runs hot, and can easily overheat in a barrel, even when the cooling system is in order.

Improvise-Adapt-Overcome

June 18, 2021 at 2:51 pm #240543Thanks guys. I test ran it again with a lower level of water in the trash can I have been using. I saw some water spraying out from a spot a little above the lower unit. I think I’m all set. Pretty sure it needs a carb rebuild – but it starts and runs so I will leave that for the next off-season. It smokes pretty heavy too. I did premix at 20:1, will go for 24:1 next time.

Fleetwin – yes, the grommet. I am pretty sure the water tube went in. It was the lower unit end that was giving me problems. I looked down with a flash light and could see a part way down inside that was a little off – blocking the shaft from inserting any further. I bumped the lower unit a little and it moved into a better position. Then the shaft inserted the rest of the way on the next try.

seakaye12 – This has definitely been used in the saltwater in the past, but since I now see some water coming out, I’m assuming I don’t need to crack it open. I’ve never been as deep into this motor as you show in those pics. It looks a little scary – but I saved the pic.

June 18, 2021 at 2:53 pm #240544Thanks aquasonic. Next time I run this, it will be on my dingy.

-

AuthorPosts

- You must be logged in to reply to this topic.