Home › Forum › Ask A Member › Drilling out top seal

- This topic has 11 replies, 9 voices, and was last updated 8 years, 5 months ago by

chinewalker.

chinewalker.

-

AuthorPosts

-

August 13, 2017 at 6:25 pm #7893

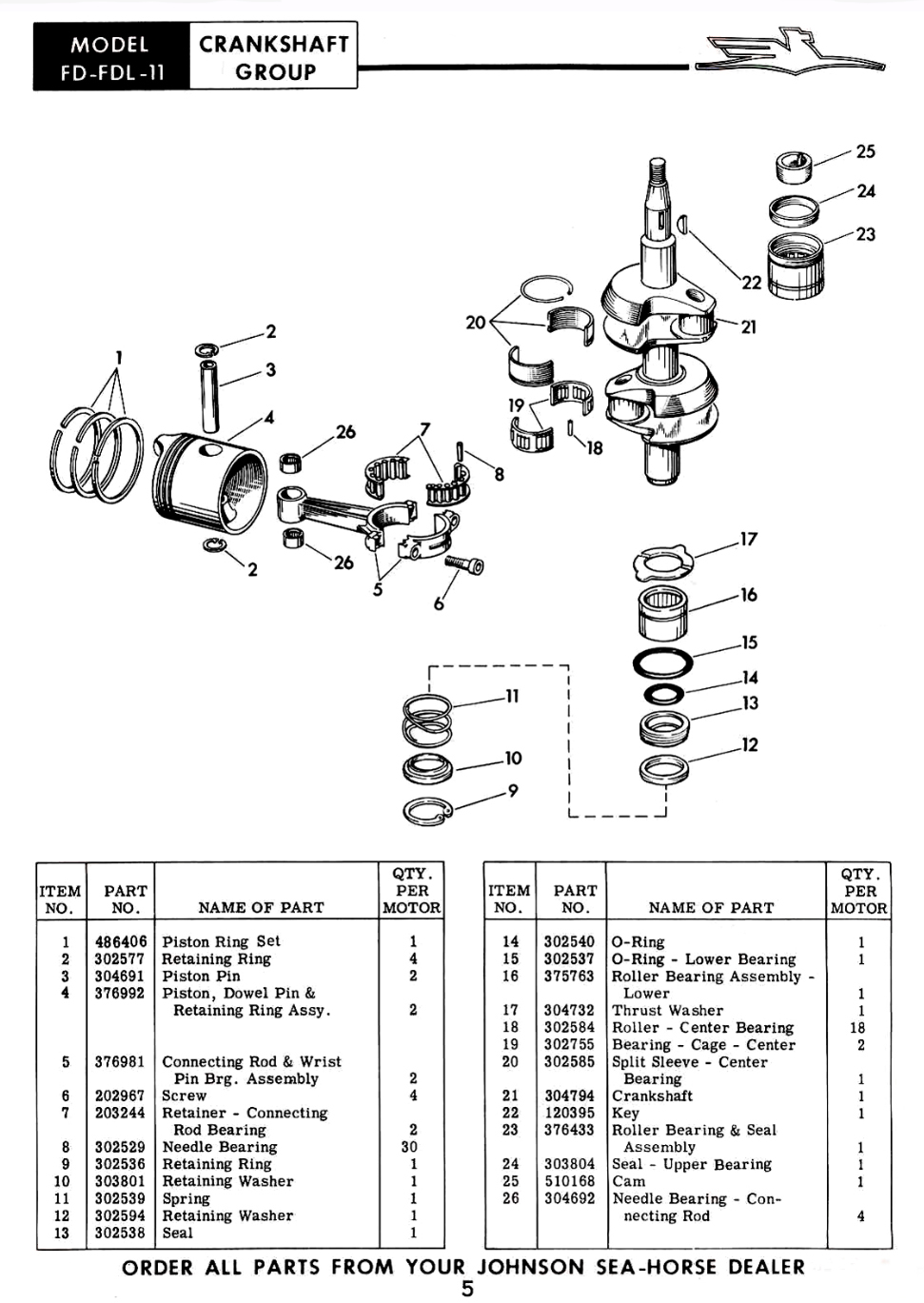

I am trying to replace my top crank seal on my ’57 Johnson 18, and having trouble getting thru the hard steel. Any suggestions on a brand of drill bit that might be sharp and hard enough to get a hole started, or a technique that you use?

I have looked on you tube and have found nothing usable. All kinds of stuff showing a leaky seal, but nothing I have found about drilling, pulling and replacing.

Thanks for any help,

Doug

August 13, 2017 at 6:37 pm #62993Whoa….. something doesn’t sound right here. I never ran

across a "hardened" seal that a normal drill bit wouldn’t

go thru. Are you sure you’re drilling the seal ?

The ME diagram shows nothing special that I can see.

http://www.marineengine.com/parts/johns … haft+GroupPrepare to be boarded!

August 13, 2017 at 9:35 pm #63002August 13, 2017 at 11:16 pm #63008quote Dougs Outboards:I am trying to replace my top crank seal on my ’57 Johnson 18, and having trouble getting thru the hard steel. Any suggestions on a brand of drill bit that might be sharp and hard enough to get a hole started, or a technique that you use?I have looked on you tube and have found nothing usable. All kinds of stuff showing a leaky seal, but nothing I have found about drilling, pulling and replacing.

Thanks for any help,

Doug

Umm, there is a seal puller out there….Shameful plug but message me…. I make them

http://www.richardsoutboardtools.com

classicomctools@gmail.comAugust 14, 2017 at 1:22 am #63034And I might add, it (puller that Richard makes) works good and is easy to use.

August 14, 2017 at 2:42 am #63046I used the seal puller before and works so well .

August 14, 2017 at 4:39 pm #63086Thanks for your responses you guys.

Trying to drill #24 in the pic.

I know about the seal puller you guys have, but really, I am on the tail end of this hobby, old and kinda working my way out of it. I am replacing the seal on my personal FD-11 to enjoy it a little more before I take off, and do not plan to replace any more seals in the future, so drilling and using 2 long screws to dislodge works well I heard.

If it’s not hard steel, guess my bits are too dull. Guess I will just go down and buy a new drill bit and try it again. Got a Drill Dr, but the bit is too small for it to sharpen.

Thanks again,

Doug

August 14, 2017 at 5:28 pm #63089If you don’t have the special tool for removing the top seal, it can be done without splitting the cases. Sharp drill bits are necessary and a bit of grease on them will help to hold the chips so they don’t fall into the roller bearing which is directly under the seal. Patience is also needed along with careful prying and pulling on the screws so nothing gets damaged.

Here’s a ’57 18 horse Fastwin having its top seal removed this way.

August 15, 2017 at 5:24 pm #63153Thanks Mumbles, just what I needed. I bought brand new bits and will be repealing and replacing that seal today 🙂

August 16, 2017 at 12:51 am #63193Seal replaced, and thanks again!

Doug

-

AuthorPosts

- You must be logged in to reply to this topic.