Home › Forum › Ask A Member › Early OMC fuel pump

- This topic has 10 replies, 6 voices, and was last updated 9 years, 4 months ago by

rudderless.

-

AuthorPosts

-

September 5, 2016 at 4:28 pm #5168

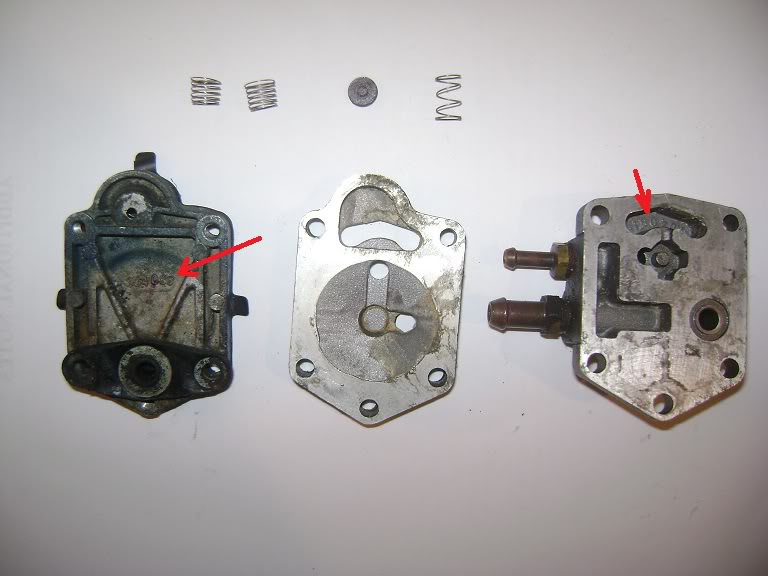

This is the pump that was on my ’62 5.5:

(Other pic rejected as "possible attack vector")

Internal parts for these not readily available.

Appears to me that the spring, etc, on the flatter end is a pulsation damper. The diaphragm has two layers and a spring to bias it’s position. It’s hard not to contrast this with the simplicity of the West Bend/Chrysler pumps, which seem to work fine. Ditto the pumps found on garden tractors, etc.

Usual procedure seems to be to replace with the small square pump, but these are not cheap if one buys them new.

I’m thinking that replacing the diaphragm with a plain piece of 0.015 diaphragm material, and forgetting about the pulsation damper and diaphragm spring, should yield a pump that pumps–assuming that the inlet and outlet valves are properly assembled.

Thoughts?

September 5, 2016 at 5:51 pm #43341I have cut diaphragms for several different pumps from the OMC 0305186 diaphragm used in all the early V4s. The part is fairly large so smaller ones can be easily cut from it. Not sure about eliminating the pulsation damper.

http://www.marineengine.com/newparts/pa … OMC0305186

September 5, 2016 at 6:57 pm #43351quote outbdnut2:I have cut diaphragms for several different pumps from the OMC 0305186 diaphragm used in all the early V4s. The part is fairly large so smaller ones can be easily cut from it. Not sure about eliminating the pulsation damper.http://www.marineengine.com/newparts/pa … OMC0305186

I’m not sure either but most other pumps don’t seem to have them. No real advantage to leaving out those two parts except for making assembly a bit easier.

September 5, 2016 at 7:37 pm #43356I think a couple guys have cut up pieces of nitrile gloves to replace the diaphragm. So long as it is gasoline and ethanol resistant I think it’ll work.

September 8, 2016 at 9:58 pm #43636I finally cut a diaphragm and put it together. No difficulty making the dia. from material from McMaster-Carr. I just made it plain, ignoring the spring and its centering piece riveted into the dia. I think it will pump OK but we shall see.

The real difficulty was getting the pump together with the valves working. What finally worked was to leave the screws a bit loose and thump on the pump with a screwdriver handle.

September 9, 2016 at 9:05 am #43660quote amuller:and forgetting about the pulsation damper and diaphragm spring, should yield a pump that pumps–assuming that the inlet and outlet valves are properly assembled. Thoughts?I just made it plain, ignoring the spring and its centering piece riveted into the dia. I think it will pump OK but we shall see.

I am no fuel pump expert but I would try and come as close to the original design/intent by using all the the springs including the center spring capped with a small metal or plastic disc that will contact the diaphragm. This is how I’ve done a few of them and have had no problem.

screenshot programSeptember 9, 2016 at 1:41 pm #43673

screenshot programSeptember 9, 2016 at 1:41 pm #43673Hmmmm. If it doesn’t pump adequately I’ll have to see about installing the center spring. What’s the green material? And the source of the plastic cap?

Thanks.

September 9, 2016 at 2:15 pm #43675The green material is what Mr. Asa was referring to, nitrile gloves cut to size, bought off eBay. Ken W. originally made that suggestion and used it himself and worked well so I tried it. I’ve also have had a piece of it sitting in ethanol gas for about 6 mos. with no problem.

The plastic piece was an idea from Frank Robb…"you can use the diaphragm and diaphragm support from a 393103 kit (Sierra 18-7820)." I’ve used that and also pieces like the picture below from eBay. 304094 is actually the little metal disc that is used in that fuel pump. If you use 318375 just cut of the stem.

I think this is a good way to keep these pumps in service, whether you use the nitrile or real diaphragm material. They’re simple and easy to work on and rebuild (as long as you don’t have to make the hard to find front gasket), and they pump just fine.

I think there was a concern mentioned about the spring sliding out of position using a support/cap like these. The original riveted support has a raised center that I think was designed to prevent that. But these supports are curved around the edge and I think that once everything gets squished down there’s not enough "wiggle room" for it to go anywhere. At least the 3 I’ve done so far are holding up. Of course, your mileage may vary.

viewtopic.php?f=2&t=7648&p=39275#p39275September 9, 2016 at 3:42 pm #43683Those are good pumps. Rebuilding is the best option. The trick shown is the best trick there is to rebuild.

September 9, 2016 at 5:14 pm #43686The ultra-simple West Bend/Chrysler pumps seem to work fine without any diaphragm springs, but these are only used up to–I think–20 hp or so. Since the inlet and outlet valves are reed type, there are few loose pieces to get out of place and replacing a diaphragm is a five-minute type job. Maybe ten minutes if you have to make one. http://www.go2marine.com/product/158261 … 747-1.html

http://thumbs3.ebaystatic.com/d/l225/pi … 7389_1.jpg

Most of these are part of the transfer cover but there are remote-mounted versions:

http://www.marineengine.com/parts/mercu … 190/4A.gifMy only real point is that, at least for small motors, it doesn’t take much for a serviceable pulse pump.

-

AuthorPosts

- You must be logged in to reply to this topic.