Home › Forum › Ask A Member › Evinrude Fleetwin Model 4443

- This topic has 5 replies, 3 voices, and was last updated 8 years, 6 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

July 8, 2017 at 6:38 pm #7581

I got the Fleetwin running today. Started up on three pulls,

and it sounds "solid". No rods a knocking or other parts

crying for help. Now that I know it’s "viable", I’ll need to

get an impeller for it. It does pump, and squirts water

out it’s back side, but evidently not fast enough, as

the water is HOT.

My "screw driver" tiller handle is in sad shape.

I have a better one, that won’t unscrew, in a Sportwin.

They look the same from the outside, but not sure.

Tried heating the tiller handle where the screw driver

screws in, with a bottle torch, but the only thing I managed

to do was make the rubber handle slip. 🙁

Anyone ever use a normal tiller grip, insert the "bare" screw driver

in it, and epoxy it together?Prepare to be boarded!

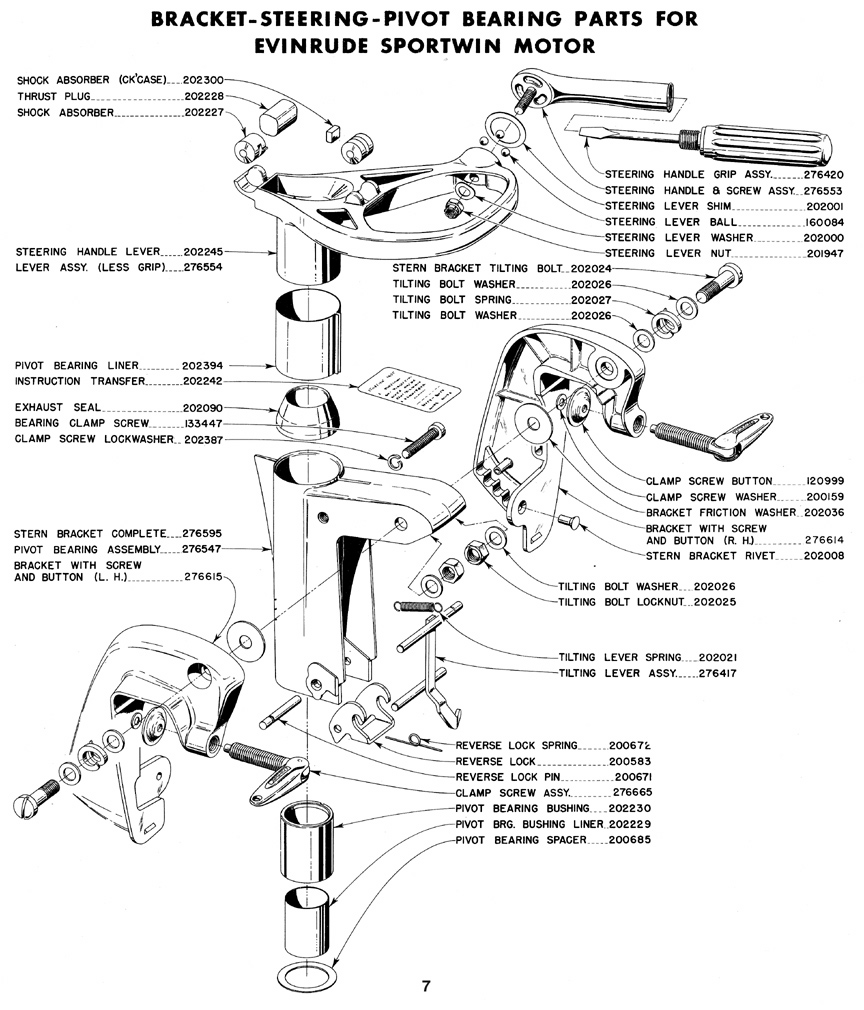

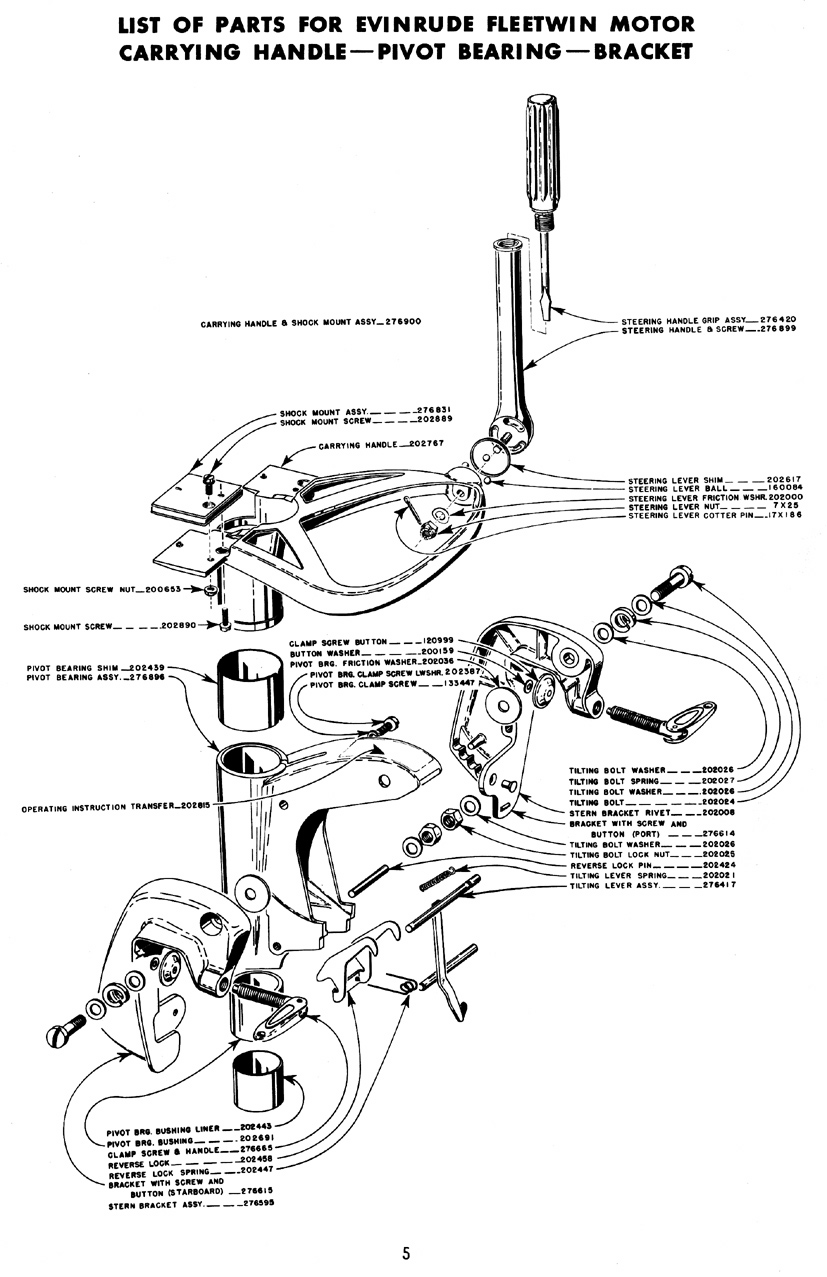

July 8, 2017 at 7:09 pm #61215I have destroyed a few screw drivers getting them apart. (A touch of grease at tune up time and they will last forever.) In these cases I have repaired them with JB Weld and disguised the repair with black tool handle dip. Yes, the 3.3 horse Sportwin and neutral clutch Fleetwin use the same 276420 screw driver handle. . . 😀

July 8, 2017 at 8:14 pm #61217

July 8, 2017 at 8:14 pm #61217Garry, good to know that the screw driver portion of the tiller handle

are the same between the Sportwin and Fleetwin. I was thinking

about swapping the whole tiller handle, but …… #1, the Fleetwin

tiller is 2" longer, and #2, what good is a tiller handle with a good

screwdriver grip if you can’t unscrew it!Your diagrams reminded me of the ball bearings in the tiller handle

swivel joint…….. and that it’s hard keeping track of three ball

bearings bouncing on the cement floor at once, all going different

directions ….. but I found them all 😉Just watched someone else’s like Fleetwin on YouTube,

and they must have drilled a hole in the Welch plug

on the starboard side of the power head. It sure would

be easier to see water flow by doing so, but any chance it

would "starve" portions of the power head of cooling water?

Guess I need to locate a new impeller before I worry about it!

https://youtu.be/UvxasSlsRFcPrepare to be boarded!

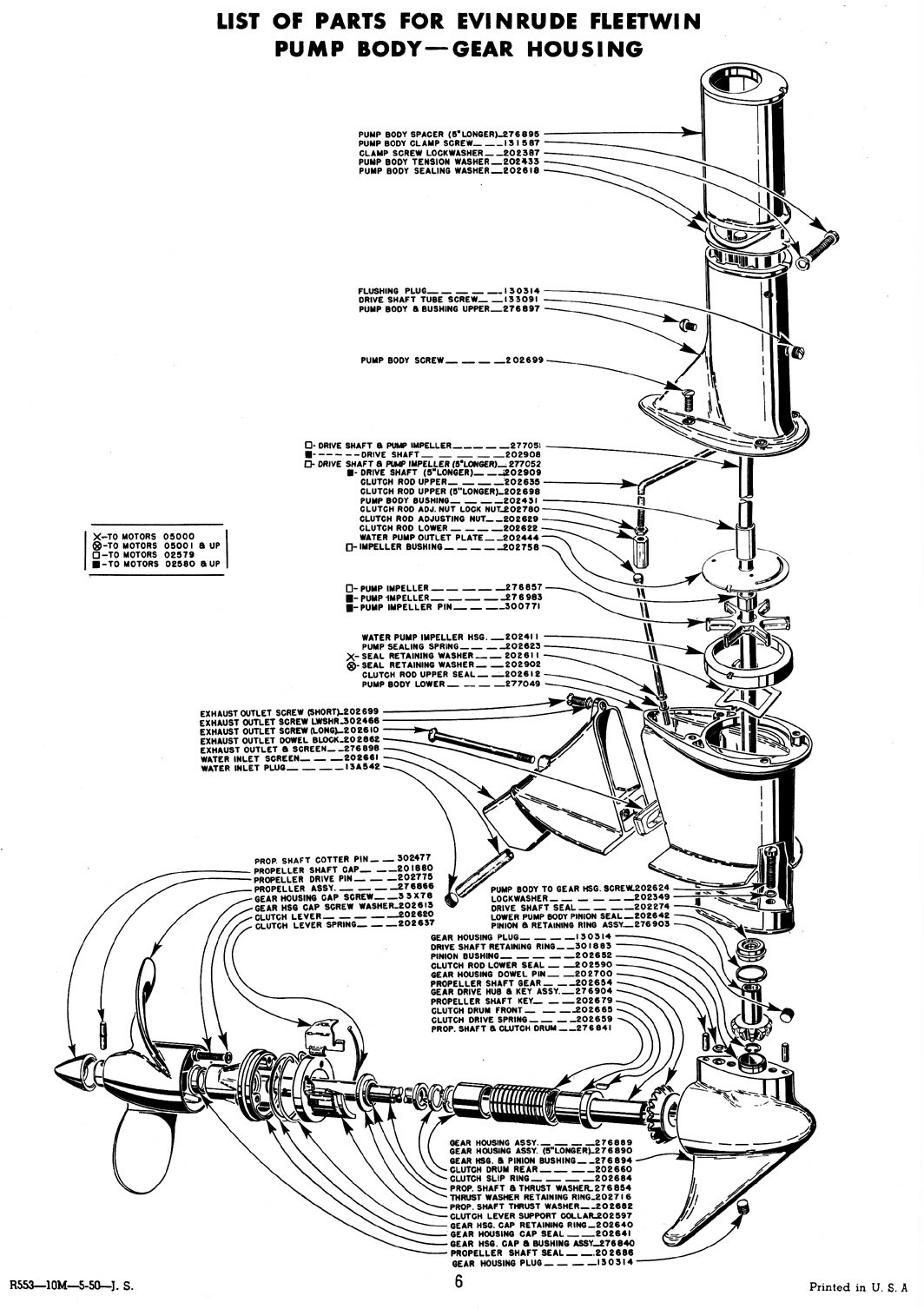

July 8, 2017 at 11:09 pm #61223The only thing I see is the flush plug on the front of the upper pump body and drive shaft housing. It covers a transfer port from the water pump and a hole their would divert some of the cooling water. I have seen some tell tail holes put in the water outlet, but all squirt warm water into the boat when the outboard is turned. . . 😆

July 9, 2017 at 4:12 am #61252

July 9, 2017 at 4:12 am #61252My screw driver handle was bent and cracked just about as yours but it wasn’t missing that big of a chunk.. but some. I used an epoxy putty for plastic to fill in the big chunks to around a 1/16th or less and then used Marine grade JB weld (it sets up slower and easier to sand and feather) to fill in the rest.I used this bumper coat to paint it.

July 9, 2017 at 12:27 pm #61267Goman, your screw driver turned out pretty nice.

I’ll probably try to get the screw driver out of the

Sportwin tiller again. Perhaps it’s time for the

torch set instead of the little bottle torch!

Or I could sacrifice the tiller arm, cutting

it off just past the threads (hopefully without

cutting off the screwdriver blade), then

put the blade in the vise and try to turn

the frozen piece of tiller with a vise grips.I ordered the recommended OMC impeller to

"fit" to size for the Fastwin. Looks like it would

need to be sanded down about 1/8" or so.

I think my dad had a little workbench belt sander,

will have to see if I can find that.

I have a little portable belt sander, but it must

turn up 10 zillion rpms, and would be hard to mount

in a vise.

I’ve never tried sanding down a rubber impeller, so

I’m a little skeptical about it working, lol.The prop shaft seal is an oddball size, of .594 or 19/32"

shaft size, and the OD is .875, or 7/8".

There’s a few NOS seals out there, but it’s against my

nature to pay $20 bucks for a sixty year old seal.

There appears to be no modern replacement though.

The drive shaft seal has me more optimistic.

Would be interested in hearing if anyone found a replacement

for the prop shaft seal !Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.