Home › Forum › Ask A Member › Evinrude Zephyr question

- This topic has 7 replies, 5 voices, and was last updated 6 years, 1 month ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

January 18, 2020 at 9:52 am #192375

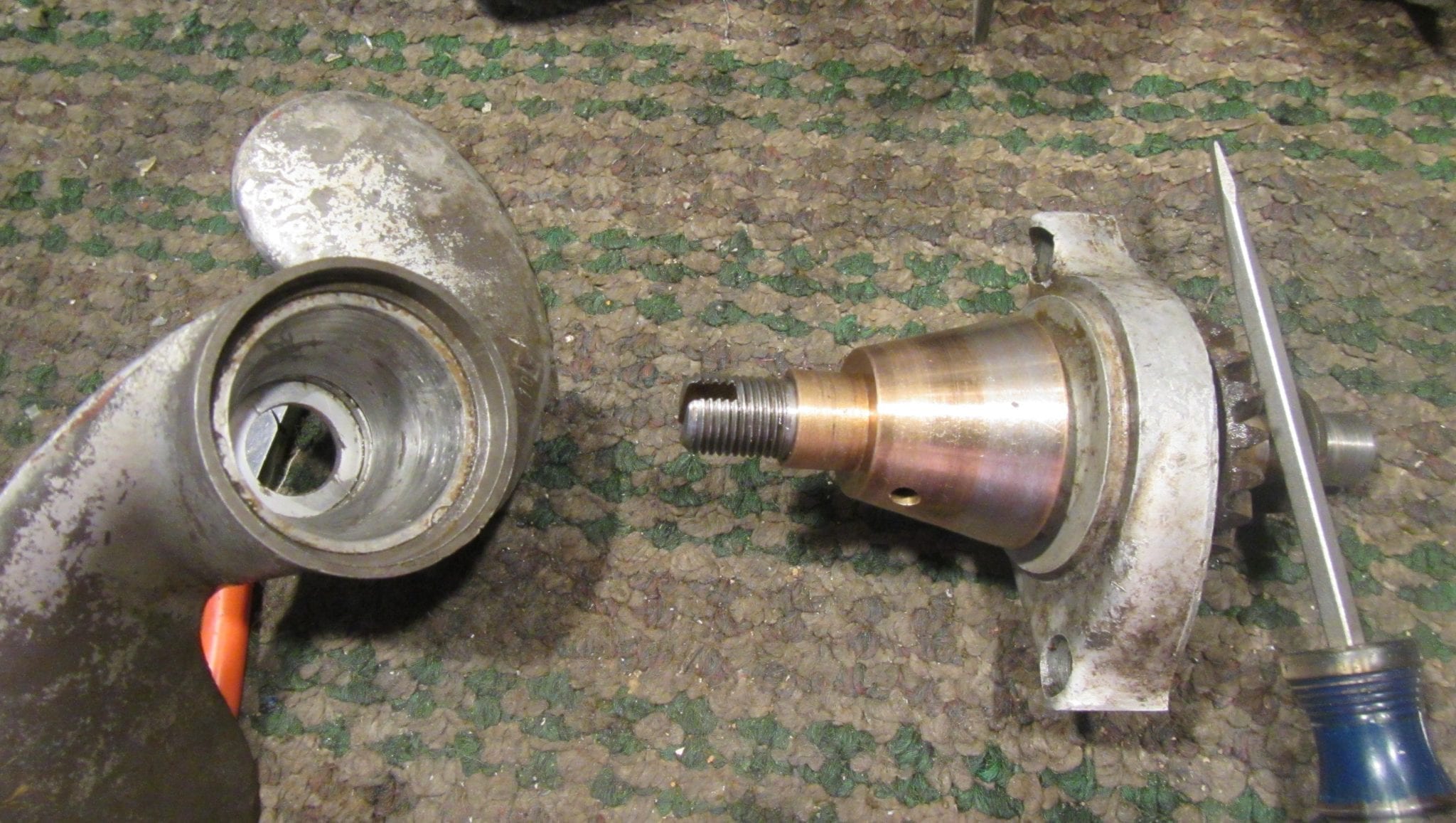

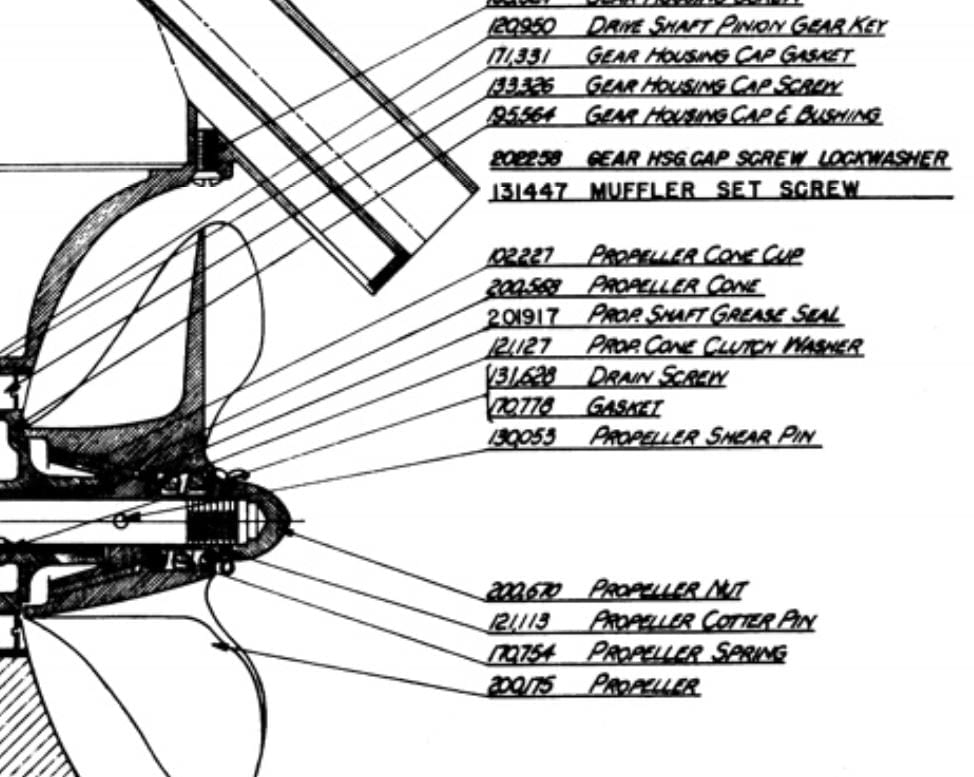

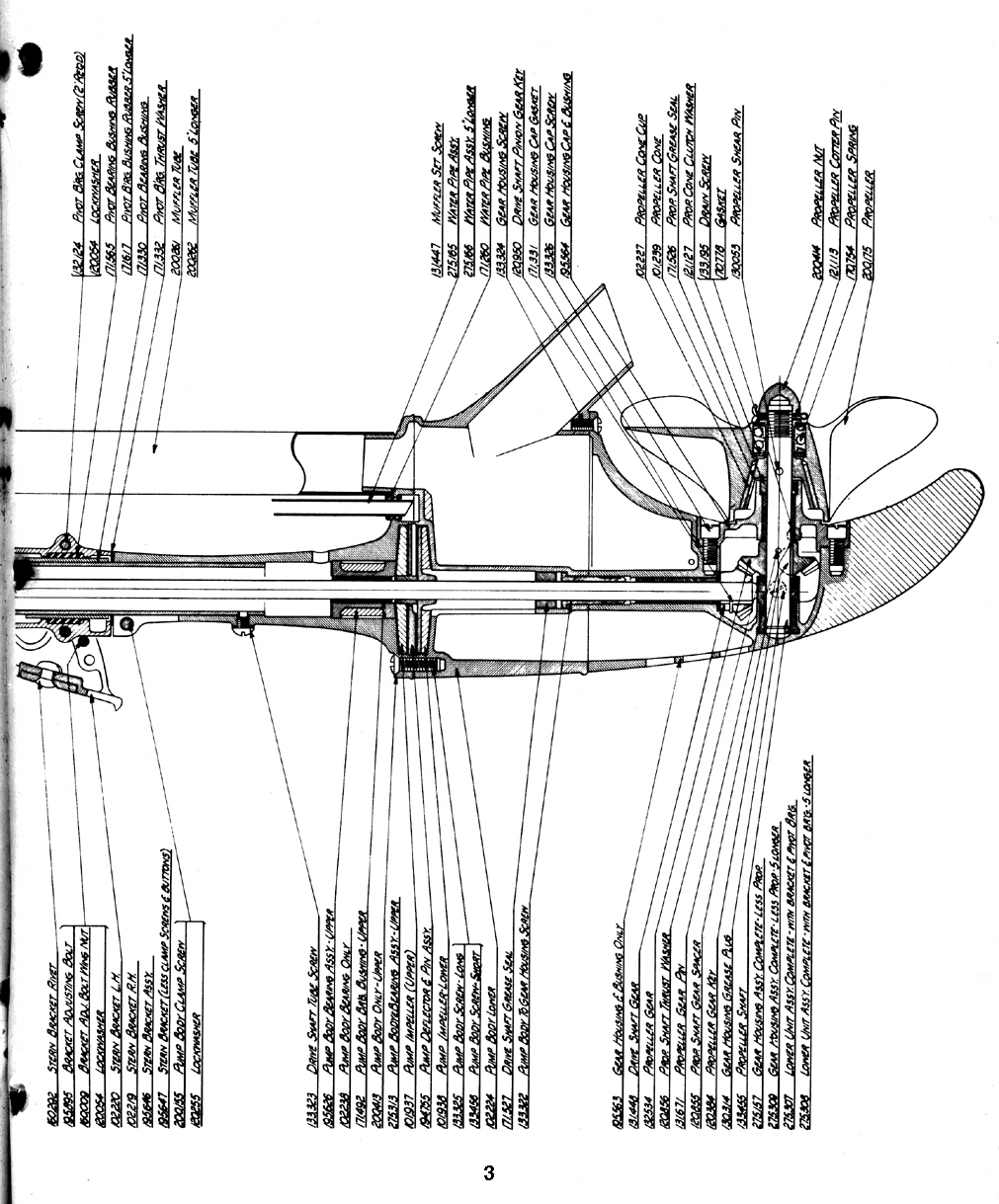

I am working on a gear foot from a 4362 Evinrude Zephyr. Clean up reveled a gasket of some sort between a brass cone shaped thing and the inside of the propeller. Is this something that is suppose to be in there? This prop protection mechanism is all new to me. It has a big spring under the prop nut to put pressure on the cone and it also has a brass shear-pin.

dale

-

This topic was modified 6 years, 1 month ago by

labrador-guy.

labrador-guy.

-

This topic was modified 6 years, 1 month ago by

labrador-guy.

labrador-guy.

January 18, 2020 at 12:15 pm #192384

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 18, 2020 at 2:59 pm #192413January 19, 2020 at 11:42 am #192519This old photo shows just the spring and nut without a washer. Not sure if that is correct though.

If the cone clutch was slipping, then I could see a washer being used to increase the friction between the cone and the prop. After cleaning them, I like to put a light coat of grease on them to help prevent them from corroding tightly together. If you hit something hard with the prop and the parts don’t release, you’ll have to take it all apart to replace the shear pin.

January 19, 2020 at 8:30 pm #192564Mumbles, mine is like yours no washer. I think I will put it back together minus the gasket and put a light coat of marine grease on the cone, the nut and spring. Mine has an aluminum nut and the flats are all worn off so channel locks are in order for adjusting the spring pressure!

thanks dale

January 19, 2020 at 11:01 pm #192584

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 20, 2020 at 2:05 am #192613Yes – it is a cone clutch.

January 21, 2020 at 1:37 pm #192724

January 21, 2020 at 1:37 pm #192724

Good eye Tubs! Yes, I did make that nut. Two of them actually as the first one had a crack in it I thought might have happened while threading it but it was the piece of stock I was using. It had a manufacturing crack running down the length of it.

-

This topic was modified 6 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.