Home › Forum › Ask A Member › Frustrating little Cub — Now Running!

- This topic has 15 replies, 9 voices, and was last updated 8 years, 3 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

October 22, 2017 at 2:56 am #66481

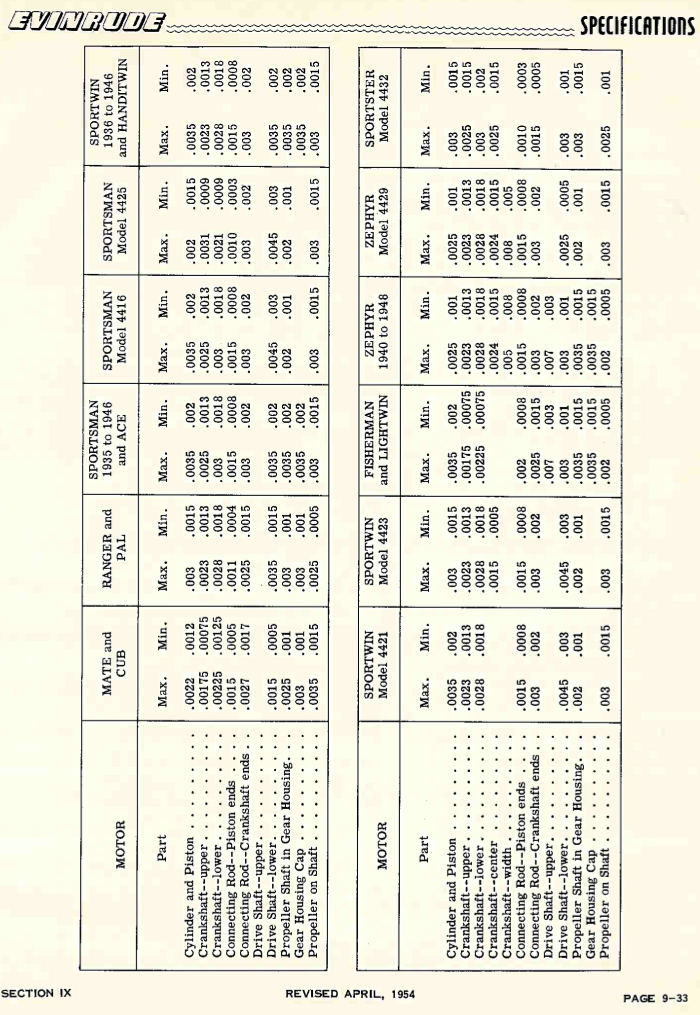

Three thousandths of an inch piston clearance is too loose for the Mate and Cub. . . 😮

October 22, 2017 at 8:17 pm #66506

October 22, 2017 at 8:17 pm #66506Is there any way to replace the crank seals once they go bad? I looked more closely at mine and figured that’s definitely the culprit

October 23, 2017 at 1:43 am #66517No seals – but you can compensate for ware by tinning the bronze bushings with silver bearing solder, then ream out to standard size. . . 😉

Garry in Tampa October 23, 2017 at 2:30 am #66518quote Mike Stroz:Is there any way to replace the crank seals once they go bad? I looked more closely at mine and figured that’s definitely the culprit

October 23, 2017 at 2:30 am #66518quote Mike Stroz:Is there any way to replace the crank seals once they go bad? I looked more closely at mine and figured that’s definitely the culprit

The oil is the seal.

Its pretty common with these.

The oil back when wasn’t what it is today

so they were wore out pretty quickly. If it

wont run using extra oil I would think the

bushings could be partially reamed out,

new pressed in with some adhesive, and then

line bored out to factory specs BUT it would

be expensive (unless you know somebody)

and they need to know what they are doing.

If they aren’t in alignment it will be in a bind.

More often they get cleaned up real well and

find a wall to hang on. There tons of people

out there looking for parts if your not into

that.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

November 7, 2017 at 6:32 pm #67118It took me a couple weeks, but I was finally able to get my hands on an appropriate cap for this little motor. Using BobD’s suggestion, I ended up getting an Orange Drop cap that was similar in specs to the one he suggested on the previous page of this thread.

I made a small bracket for it out of .030 brass shim stock. Soldered everything up and finally had a nice blue spark.

The little Cub actually fired and ran for about 4 seconds on the first pull. I finally got the needle dialed in and have it running pretty nicely now. Starts every pull and will idle down and run up nicely.

I also found that its time in the attic of that barn made its water passages a perfect home for some dirt dobbers. A little work with the air compressor made quick work of that and now I’ve got it pumping water too.

Thank you again to all that offered ideas to get it running.

Some pics of my restoration and the finished motor are at this link…

November 7, 2017 at 10:32 pm #67126Nice job! Looks like you’re ready to go into

the restoration business!Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.