Home › Forum › Ask A Member › Fuel pump repair kit

- This topic has 11 replies, 8 voices, and was last updated 10 years, 4 months ago by

dan-in-tn.

-

AuthorPosts

-

October 24, 2015 at 2:17 am #2841

hi is there a repair kit for the small square fuel pump part no. 388684? \if so can you provide me the part number for it?

Thanks

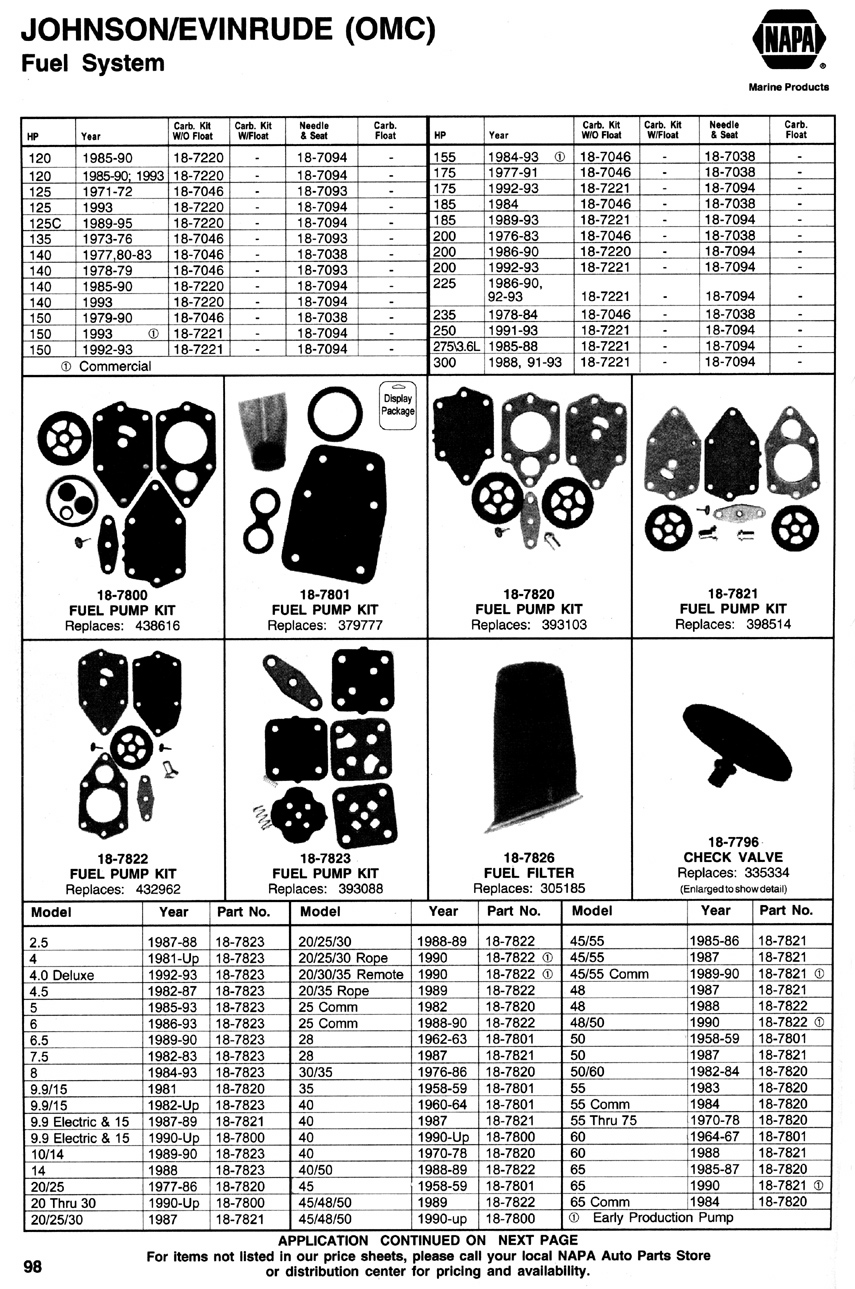

October 24, 2015 at 2:34 am #25939393088 sounds like a good number!

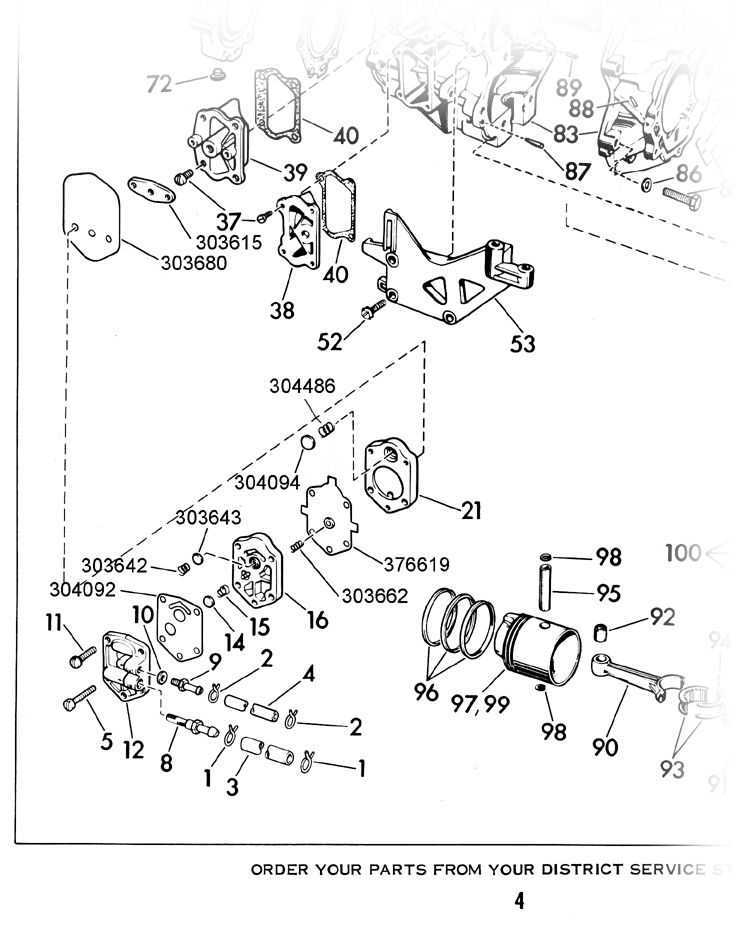

October 24, 2015 at 2:38 am #25941I don’t know if this is any help – It’s ah earlier pump …

Then there is this – 393088

October 24, 2015 at 2:42 am #25942

October 24, 2015 at 2:42 am #25942I have never had good success rebuilding fuel pumps. Maybe it is just me. I consider myself pretty handy at fixing stuff, but never had much success with pumps.

http://www.ebay.com/itm/New-OEM-Johnson … 1846029011

October 24, 2015 at 2:53 am #25944quote Greg O:I have never had good success rebuilding fuel pumps.

http://www.ebay.com/itm/New-OEM-Johnson … 1846029011Having a clean work area and a way to keep the parts aligned really helps. So does following the instructions to a T.

October 24, 2015 at 7:23 am #25956The reason they quit supplying parts for that early pump was because the cost of the labor to repair them was more than the cost of a whole new pump. At least, that was the official reason given back then, in a different time.

Personally, I find that rebuilding the square style pumps to be a PITA. If the person doing it is a pro in the shop, at normal labor rates, the original reasoning still applies. Some other pump styles are so simple and well worth repairing.

October 24, 2015 at 2:31 pm #25973I agree Frank R. They are a pain getting everything lined up and keeping springs in place. I don’t mess with them anymore.

October 24, 2015 at 10:21 pm #26002they are not bad if you read 3 times and understand the instructions

work on a clean surface

glue the little mushroom caps on their respective springs with a touch of crazy gluenext step is to glue the springs on their nipples (plastic) to keep them from flying away to nowhere ….with a touch of crazy glue

pile the layers and reassemble do a blow test when done

Joining AOMCI has priviledges 🙂

October 25, 2015 at 12:45 am #26005Frank, who was it that showed us his jig and step by step procedure for building the little pumps on the old site? I don’t like to build them either, but that was a pretty impressive setup he had. Just one of the many things we lost off the old site.

Dan in TN

October 25, 2015 at 1:52 am #26009A couple of the extra screws which come with the new coils and have their heads removed can be used to make a little fixture to help keep everything where it should be while working on the pumps.

-

AuthorPosts

- You must be logged in to reply to this topic.