Home › Forum › Ask A Member › Gear case lapping question

- This topic has 31 replies, 15 voices, and was last updated 10 years, 2 months ago by

jeff-register.

-

AuthorPosts

-

October 19, 2015 at 12:48 pm #25753

Where exactly are you seeing the leak? I can’t say as I’ve ever had a problem resealing the skeg as long as it’s the matching skeg to the housing. Is the spaghetti seal cut square and overlapping the gear case head a bit? The 847 is thick and should adequately seal up any small imperfections without aggressive sanding. Are you using the 847 around the bolt holes and into the threads themselves? I like to goop it on reasonably thick around all the mating surfaces and the o-ring being careful not to allow much excess 847 to squeeze into the gear case.

Wayne

Upper Canada Chapteruccaomci.com

October 19, 2015 at 2:48 pm #25758I have had issues with Scott Attwater clam shells leaking from the threaded holes pulling up & making a high spot. I use a flat surface to check for that is all. I never polish the mating surfaces. I leave the factory surface alone as a little roughed up will bond better. Cut the seal with square ends & with a little preload on the ends. Get the mating surfaces acetone clean then apply sealer. I let the sealer cure for a few days before adding oil as well. Check to be sure they are still a machined pair.

October 19, 2015 at 6:04 pm #25763Like Papster says, it is the spaghetti seal that seals the gearcase halves together. Have you checked the surfaces for flatness on your surface plate/glass? It is surely possible that the gearcase is distorted after hitting something causing the pieces not to sit flat together.

Are the two halves both from the same gearcase? These pieces really are matched sets, and should not be mixed and matched. I know, I know, guys do it all the time. But, maybe you are the unlucky one.

Papster offers sound advice when advising you to mark the spot(s) where the gearcase is leaking, this will allow you to have a much closer look at the problem area, perhaps the casting is porous or cracked.

Finally, you must be real careful not to remove too much/any material from those halves. The halves must fit properly around the bearings/housings, or you will distort the pieces while tightening the screws.October 21, 2015 at 12:50 am #25826Thank you for replies. Got it soaking now to get all the 847 off. Will go back and check flatness tomorrow. It is leaking in 3 places, again only after going up to 10 plus psi but definitely from between the halves. About the third screw from rear on both sides. Then one from the front on one side of rear. Checking under water with Stevens tester. Looking for bubbles.

As far as I know halves are mates but anything is possible.

Definitely in the camp that my "lapping" process messed it up from normal. Lesson learned. Going to try it one more time, it a no go then I will put on a donor with no special surface treatment. Will update all this weekend on results.

Thank you for help,

Allen

October 21, 2015 at 3:41 am #25835Hopefully not too much has been lapped off that the spaghetti and 847 wont fill the gap !

I think it was Frank Robb that said he uses a hand held impact driver to snug the halves together. I have had to use a wrench on my square shank Craftsman screwdriver to get some halves to seal. Knock on wood that I haven’t stripped any yet 😮

October 21, 2015 at 3:44 am #25836I just put in the the "spaghetti seal" and slap some "ackempuckee" (847) on it, as my Dad used to say. Dad called anything sticky, slimey, or gooey that you use to seal, glue or lube, "Ackempuckee". One of my favorite catch-all words….

October 21, 2015 at 4:12 am #25837Why are you going to 10 psi ?

No need for pressures like that. Less than 5psi is more than adequate for that style gearcase and seal arrangement.

October 21, 2015 at 11:37 am #25846The more time I spend with these darn clam shell gearcases, the more I get frustrated with the designs. Everything must be right for a good seal, and you have a big mess to clean up if you have to go back in there to reseal again.

Again, just one picture is worth a million of my words. But, I am frustrated that the skeg retaining screws are inside the spaghetti seal, so any imperfection on the screws or skeg mating surface will create a leak. Too bad OMC didn’t design the screws with gaskets or orings to ensure a good seal.

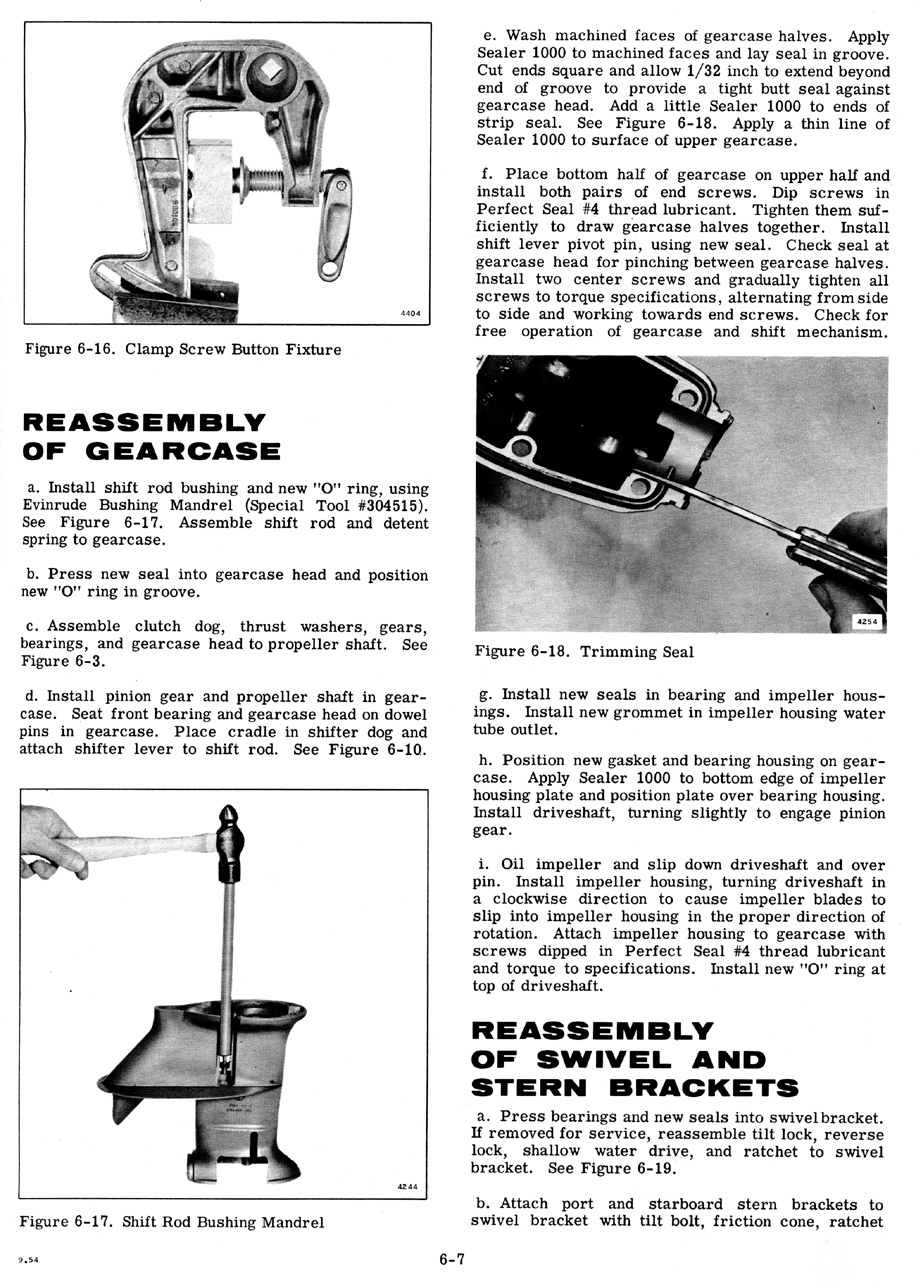

Is it me losing it, or has anyone else questioned why the spaghetti seal does not but up against the prop shaft seal/bushing oring, seems like an obvious leak area. I know, probably just me over thinking it.October 21, 2015 at 3:49 pm #25852There is the danger of having gaps as material is sanded/polished away because the inside still has to accommodate the bearings and seal housings that were in side. The most common leaks are where the spaghetti seal butts against the rear bearing & seal housing. The ends MUST be cut perfectly square . . . I find this is most easily done with the seal out of the L/U and flat on the workbench, using a very sharp X-acto knife. I trust everyone knows the Marprox Sealer 1000 has been replaced by Scotch Grip 847

. . . 🙂

October 26, 2015 at 1:57 am #26072

October 26, 2015 at 1:57 am #26072Well for the update. Put the bearings back in without the gears and as suspected, suggested, and hypothesized it is my error. I took off too much material and have just the slightest rocking over the bearing od’s between skeg and housing. I compared this to another un touched version and no rocking was present.

Thanks to all for the help. Hard lesson learned. On the positive side Now I have a gear case for a motor mail box image that my wife does not know about….yet

-

AuthorPosts

- You must be logged in to reply to this topic.