Home › Forum › Ask A Member › have u repaired hood clasp hole? 1955 RD-17 25 hp Johnson

- This topic has 10 replies, 10 voices, and was last updated 3 years, 4 months ago by

opposedtwin.

opposedtwin.

-

AuthorPosts

-

August 16, 2022 at 11:27 am #264454

What I was thinking about doing is taking the hood to a welder.

Have them lay a piece of solid copper wire in the remaining part of the hole.

Have the welder build up the embossment.

Then grind to shape.

I am thinking the built up aluminum would not adhere to the copper?

or another idea –

Just break out the JB weld and build the embossment up my self.

Maybe it would be strong enough?

What are your thoughts?

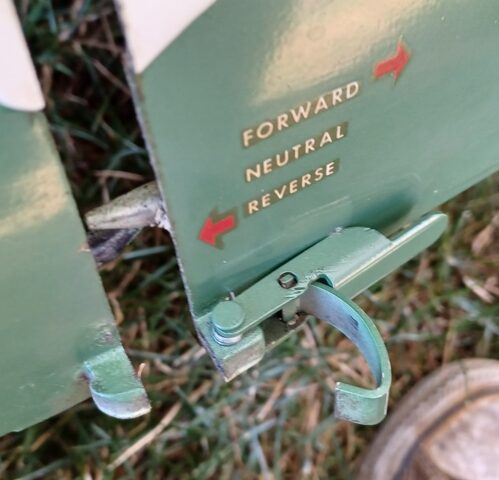

I have included picture of a good hood clasp and the broken hood claspAugust 16, 2022 at 3:24 pm #264463how about redrilling for the pin???????

August 16, 2022 at 3:33 pm #264464Dave- I’m not sure what you mean

There is not enough materiel to drill.

please compare the two pictures of a good one and the bad one (arrow)August 16, 2022 at 8:55 pm #264478A skilled welder should be able to build that broken area up and reshape it and then you could just rebore the hole……….unfortunately the paintwork would be damaged.

A dremel tool would be my choice to do the reshapingMonte NZ

August 17, 2022 at 8:41 am #264483Consider sourcing a good used one….. use a WTB add on our classifieds page.

August 17, 2022 at 9:16 am #264484

My approach would be to reshape the piece with files after welding.

If you’re still using grandpas files go to an Ace hardware store and

get some new Nicholson files. Its what I use to reshape coil

laminates and a new file goes through the steel like butter. Then

drill the hole from the bottom when you have the proper shape. I think

that is what Dave was suggesting. Its going to be a challenge to

find a way to hold the cover so you can work the cover if you do

decide to file it.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 21, 2022 at 9:17 pm #264682I have a ’57 Javelin cowling that I plan on doing the same thing to. I’ll just have the extrusion built up with a TIG welder. I will then shape the weld and re-drill the hole. I am not worried about the paint since I will be sandblasting and repainting the hood anyway. Please let me know how yours turns out. What you learn will be a benefit to me.

-

This reply was modified 3 years, 5 months ago by

JZago.

JZago.

August 22, 2022 at 5:36 am #264708Around here, if I had to pay a welder to do that, it would cost more than the motor was worth. I have never actually tried this; but just looking at it, what I would try is this: I would cut and file off what’s left of the broken area. Then I would make a small aluminum block, the same depth and height as the original part but 50% longer, fore and aft. It looks like there is enough swing room on the hasp, to do that. Then I would drill my pivot hole. Next, I would carefully drill and tap two mounting holes in the little block , with corresponding holes in the cover, and attach with a couple of maybe 4-40 pan head machine screws. Just a thought. It would not be easy but it would save welding cost and paint.

Long live American manufacturing!

-

This reply was modified 3 years, 5 months ago by

billw.

August 22, 2022 at 9:34 am #264712Here is a way using a milled piece of aluminum. Hint: Be sure to make the drilled nub high enough that the drilled hole can be well above the surface of the hood. Notice that the clasp covers one of the screws.

August 24, 2022 at 11:19 am #264871what if you were to reverse the clip direction.

it would provide a solid base by just drilling a new mounting hole the ” hook-part” and then just reshape the other part so the hook can grab it.

Joining AOMCI has priviledges 🙂

-

This reply was modified 3 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.