Home › Forum › Ask A Member › Impeller stops sucking at higher speed

- This topic has 11 replies, 7 voices, and was last updated 4 years, 6 months ago by

crosbyman.

-

AuthorPosts

-

July 13, 2021 at 4:15 pm #242757

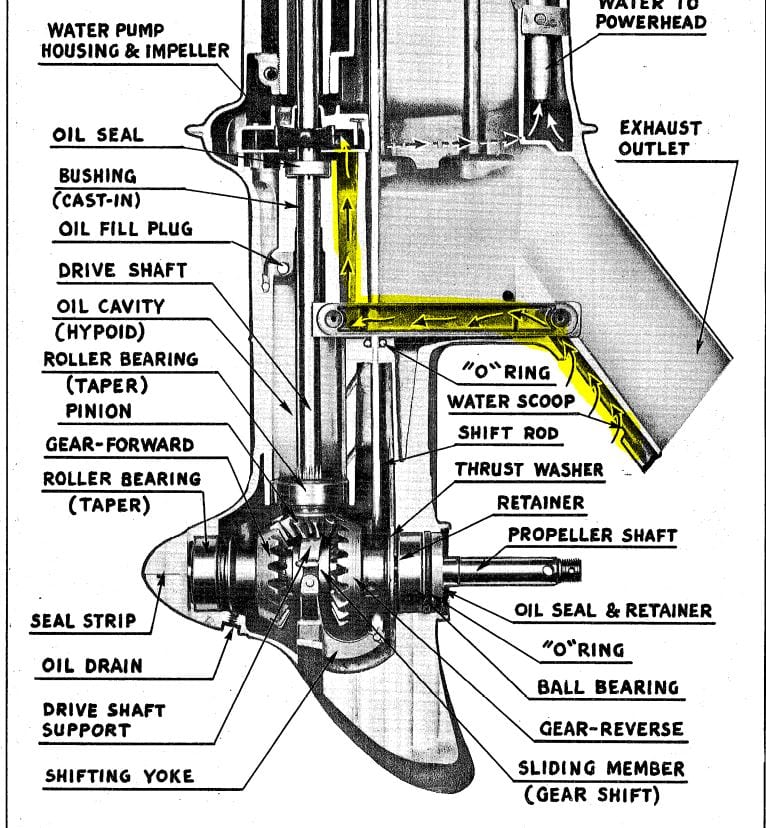

I have a big twin 35hp 1958 that spits water out beautifully out the exhaust while at idle or low speed. As soon as it’s on plane the water doesn’t come out at all. The transom is much shorter than this motors longer shaft. The cavetation plate is a good few inches below the bottom of the hull. Could this be why at high speeds the water isn’t getting picked up ?? Thanks guys !

July 13, 2021 at 6:21 pm #242765Have you checked the impeller and base plate/ housing, does the motor overheat, you can get a digital infrared thermometer on the Jungle website for under $20 to check head temp easily while out on the water .

1 user thanked author for this post.

July 13, 2021 at 7:37 pm #242780I didn’t run it too long because I didn’t want it to overheat. Splashed some water on the head and it sizzled very quickly and with vigour! When I was on a plane, there was zero water coming out the exhaust. I just installed the impeller today and it’s in good shape. As soon as I go back to idle speed, it’s spitting water again. So I don’t think it’s the housing for the impeller itself. I am wondering if it’s because I have a long shaft on a short transom

July 13, 2021 at 8:01 pm #242794Look behind the prop. Is the plug in place at the bottom end of the intake screen? Is the intake screen even there?

July 13, 2021 at 8:11 pm #242795Holy crow, now that you mention it, that little screen is broken right off. Does that normally direct water upwards at high speeds ? That would explain it though.

July 13, 2021 at 10:05 pm #242798Yep, the propeller force-feeds water to the pump inlet at higher speeds

July 13, 2021 at 11:20 pm #242803You really have no idea how much I appreciate this information. You just save me a lot of troubleshooting and trying and swearing… This website and its members are so valuable, YouTube has nothing on this place. Thanks again!!

Now I need to find a new gear case SMH 🤦♂️

July 13, 2021 at 11:37 pm #242804Holy crow, now that you mention it, that little screen is broken right off. Does that normally direct water upwards at high speeds ? That would explain it though.

You would still get water to the pump if the screen is missing but it’s the plug which is important. The small aluminum plug seals the gallery the screen is in and if the plug is missing, water would go through the screen and straight out the back instead of up to the pump.

-

This reply was modified 4 years, 6 months ago by

Mumbles.

Mumbles.

July 14, 2021 at 8:00 am #242813July 14, 2021 at 12:29 pm #242841If the intake screen/plug are both OK, then I would suspect the sealing surface between the SS impeller plate and the gearcase housing. At slow speeds, the water level is high inside the gearcase, so there wouldn’t be much of an effect…But, once the boat speed increases, the water level inside the gearcase drops allowing air to be drawn in under the SS impeller plate…This is a weak link in many of the OMC gearcases due to aluminum corrosion/erosion in that area…. Oftentimes, guys break off the little impeller housing screws also, lousy repair jobs, or just leaving the broken screw there will lead to poor sealing also…

-

This reply was modified 4 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.